Nano-silicon dioxide and nano-silicon nitride composite material and preparation method thereof

A kind of technology of nano silicon dioxide and nano silicon nitride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

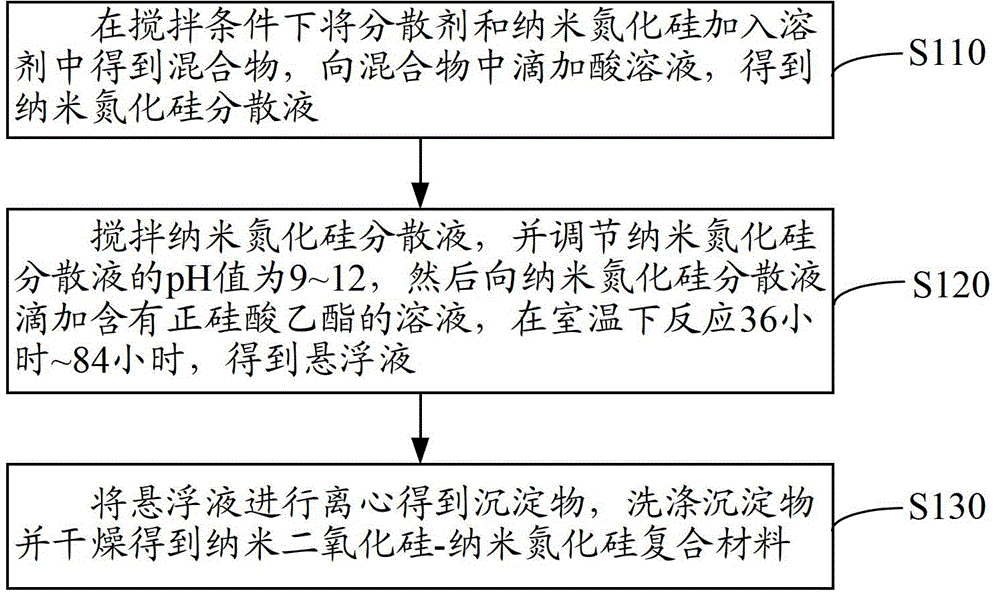

[0029] see figure 1 , the preparation method of the nano-silica-nano-silicon nitride composite material of an embodiment, comprises the steps:

[0030] Step S110: adding the dispersant and nano-silicon nitride into the solvent under stirring condition to obtain a mixture, and adding an acid solution dropwise to the mixture to obtain a nano-silicon nitride dispersion.

[0031] The dispersant is used to uniformly disperse the nano-silicon nitride to obtain a stable nano-silicon nitride dispersion.

[0032] The dispersant is preferably at least one selected from silane coupling agent KH-560 and silane coupling agent KH-550.

[0033] Nano-silicon nitride is preferably nano-silicon nitride with a particle size of 15 nm to 80 nm.

[0034] The solvent is at least one selected from ethanol, acetone and butanone.

[0035] In order to improve the dispersion effect of nano-silicon nitride, the process of preparing nano-silicon nitride dispersion liquid is to add dispersant and nano-si...

Embodiment 1

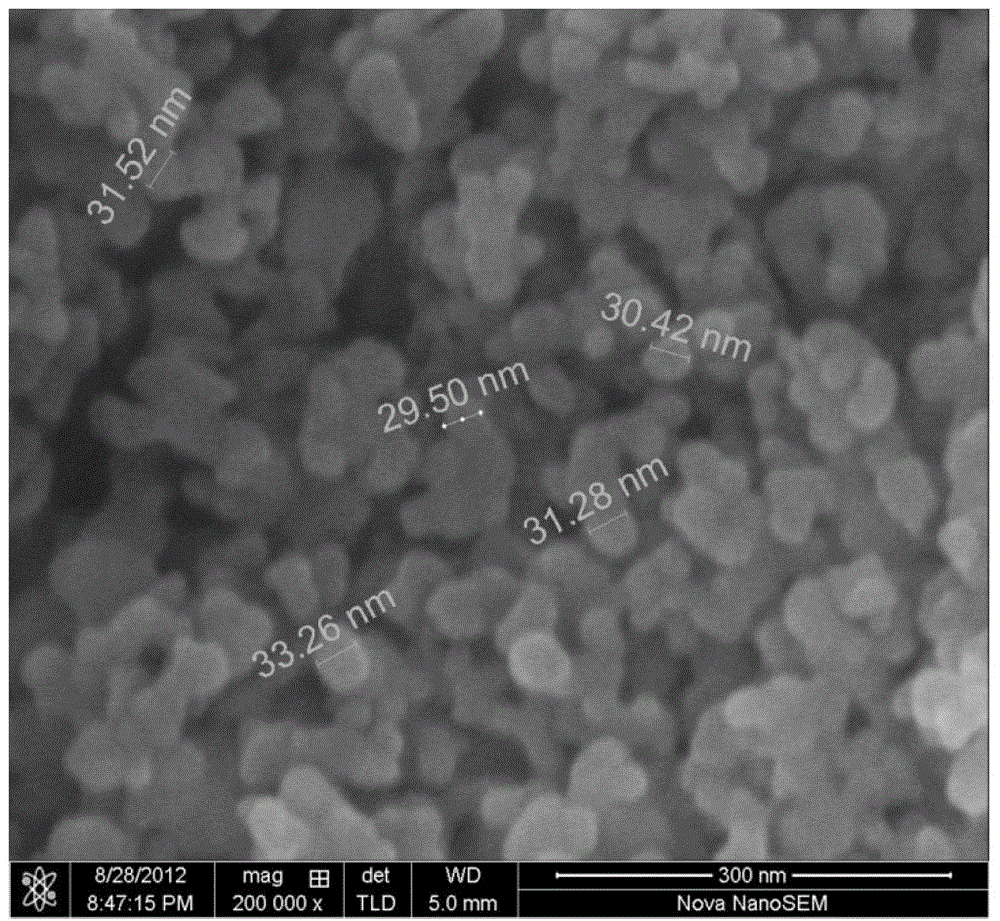

[0057] Preparation of Nano-SiO2-Nano-Silicon Nitride Composite Material

[0058] (1) Under the action of stirring and ultrasonic waves, weigh 0.1g of silane coupling agent KH550, 5g of nano-silicon nitride and add it into 10mL of acetone to prepare a mixture, and then slowly add dropwise an oxalic acid solution with a pH of 4 to it to obtain Nano-silicon nitride dispersion with better dispersibility;

[0059] (2) Place the nano-silicon nitride dispersion at 1000rpm and stir for 10 minutes, then add ammonia water dropwise to adjust the pH of the nano-silicon nitride dispersion to 9, and then slowly add the dissolved amount of ethyl orthosilicate that has been ultrasonically mixed uniformly 15 g of a solution containing ethyl orthosilicate was reacted at room temperature for 64 hours to obtain a white suspension, which was filtered to obtain a precipitate;

[0060] (3) The above precipitate was ultrasonically washed with acetone, and then centrifuged. The washing and centrifuga...

Embodiment 2

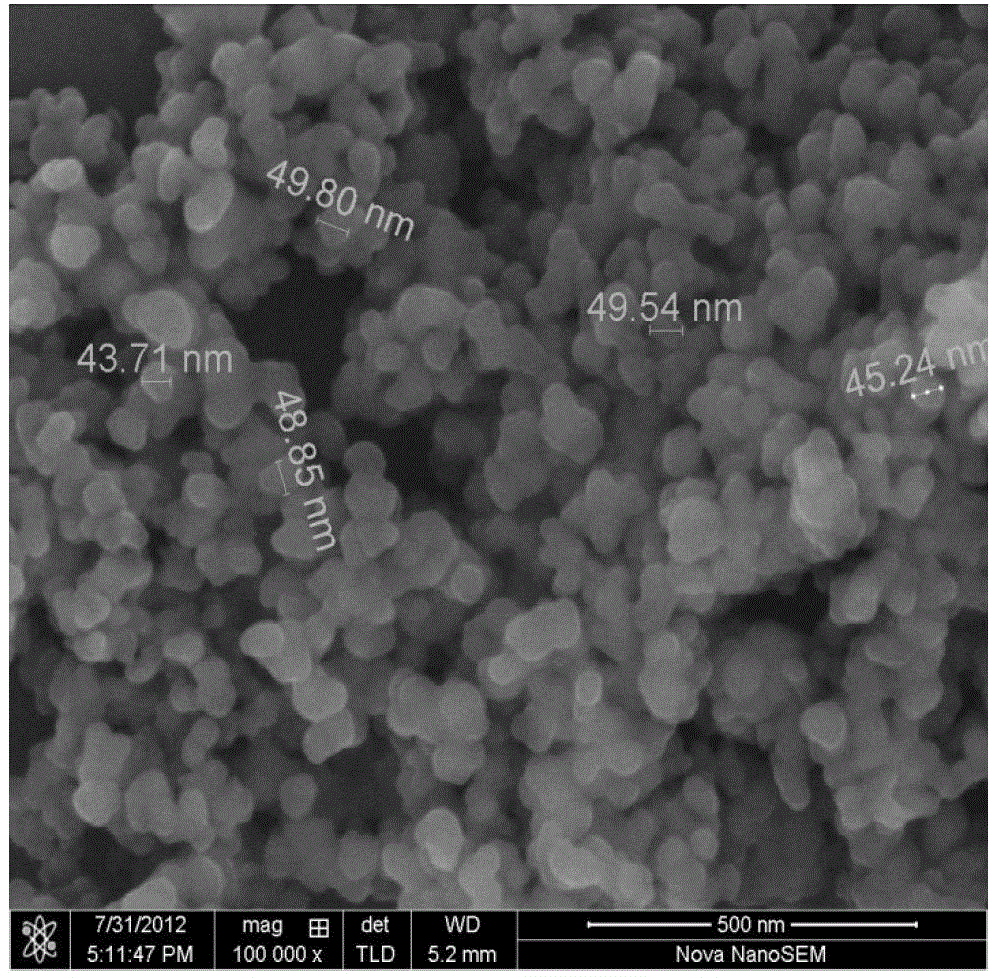

[0064] Preparation of Nano-SiO2-Nano-Silicon Nitride Composite Material

[0065] (1) Under the action of stirring and ultrasonic waves, weigh 0.2g of silane coupling agent KH550 and 10g of nano-silicon nitride into 20mL of ethanol to prepare a mixture, and then slowly dropwise add an oxalic acid solution with a pH of 5 to it to obtain Nano-silicon nitride dispersion with better dispersibility;

[0066] (2) Place the nano-silicon nitride dispersion at 1300rpm and stir for 15 minutes, then add ammonia water dropwise to adjust the pH of the nano-silicon nitride dispersion to 10, and then slowly add the dissolved amount of ethyl orthosilicate that has been ultrasonically mixed uniformly 30 g of a solution containing ethyl orthosilicate, reacted at room temperature for 50 h to obtain a white suspension, and filtered the suspension to obtain a precipitate;

[0067] (3) Ultrasonic wash the above precipitate with ethanol, then centrifuge, wash and centrifuge for 5 times to obtain a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com