Full-degradation deworming mulching film and preparation method thereof

A fully degradable and mulching technology, applied in animal repellants, animal husbandry, applications, etc., can solve problems such as inability to absorb and utilize crops, crop production reduction agricultural operations, and harvest decline, so as to maintain full biodegradability and reduce harm to humans. Threat, effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

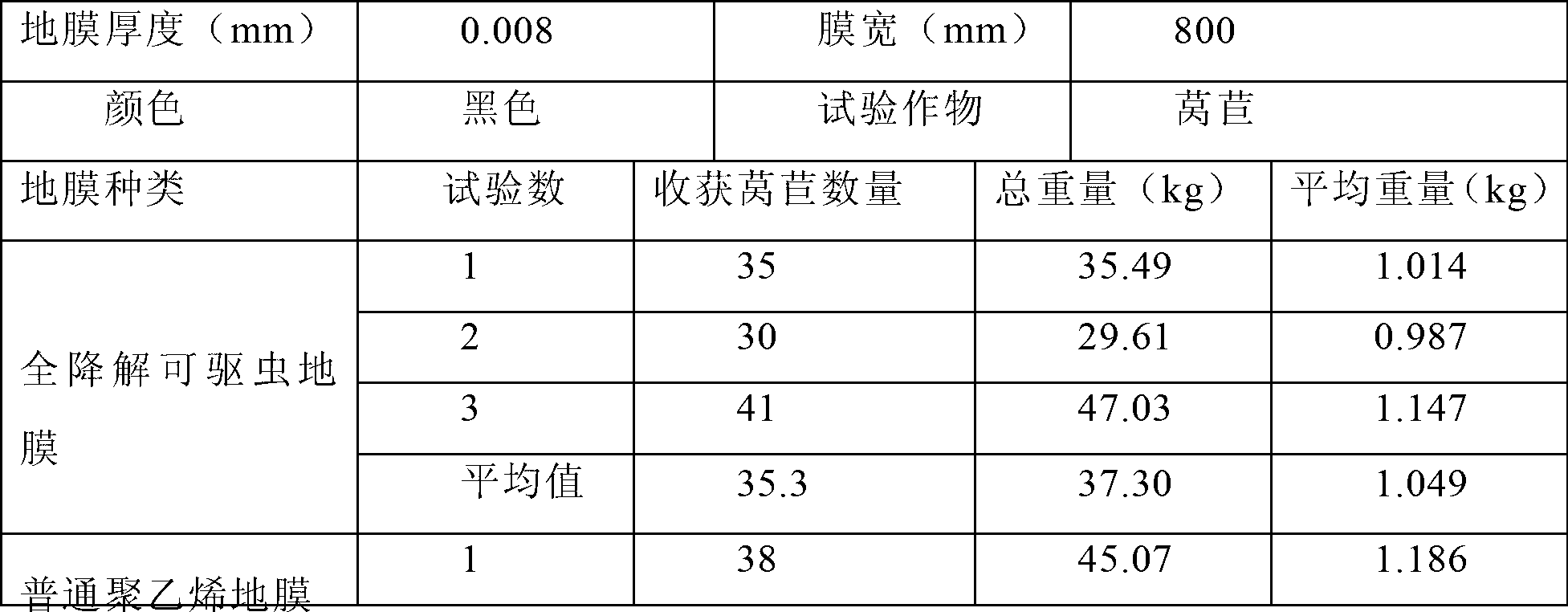

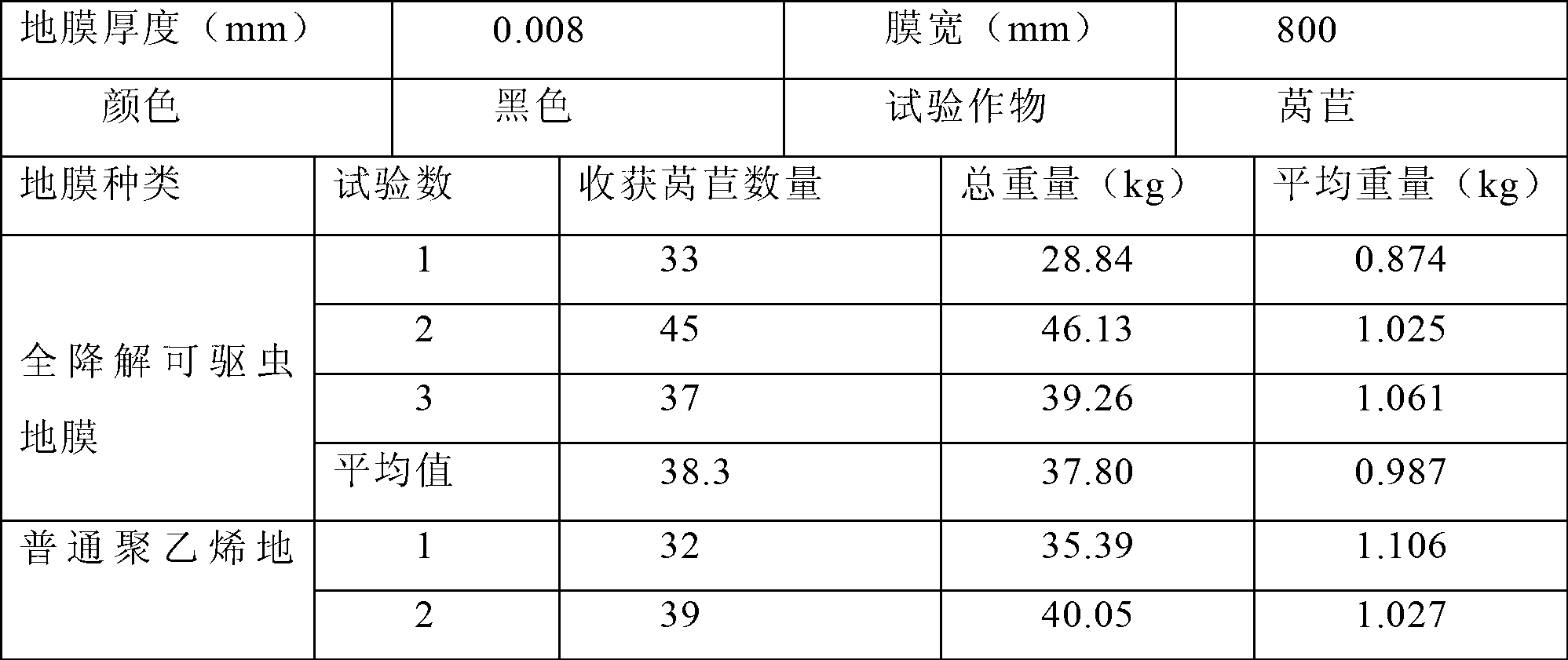

Examples

Embodiment 1

[0043] The diatomite powder was completely soaked in peppermint oil, ultrasonically oscillated for 4 hours, suction filtered, and dried to obtain diatomite powder loaded with peppermint oil. Disperse the powder in a glycerol solution of polyvinyl alcohol, spray the mixture into an inert hot air current to make the droplets shrink into a spherical shape, and then dry to obtain peppermint oil microcapsules.

[0044] 40 parts by mass of PBAT, 20 parts by mass of polylactic acid, 20 parts by mass of cornstarch, 5 parts by mass of glycerin, 2 parts by mass of BASF chain extender JONCRYL ADR-4368, 5 parts by mass of peppermint oil microcapsules and 8 parts by mass of light Calcium carbonate is mixed evenly in a high-speed mixer, and then the mixture is mixed in a twin-screw extruder, and the temperature of each section of the twin-screw extruder is set to T 1 =140°C, T 2 =150℃, T 3 =150℃, T 4 =155℃, T 5 =155℃, T 6 =155°C, the speed of the twin-screw extruder is R=300r·min -1; ...

Embodiment 2

[0049] The diatomite powder was completely soaked in cinnamon oil, ultrasonically oscillated for 6 hours, filtered and dried to obtain diatomite powder loaded with cinnamon oil. Disperse the powder in a glycerol solution of polyvinyl alcohol, spray the mixture into an inert hot air stream to make the droplets shrink into a spherical shape, and then dry to obtain cinnamon oil microcapsules.

[0050] Mix 30 parts by mass of PBAT, 30 parts by mass of polylactic acid, 10 parts by mass of tapioca starch, 5 parts by mass of ethylene glycol, 20 parts by mass of cinnamon oil microcapsules and 5 parts by mass of talc in a high-speed mixer, and then mix the mixture in Mixing in the twin-screw extruder, the temperature of each section of the twin-screw extruder is set to T 1 =155℃, T 2 =160°C, T 3 =165°C, T 4 =165°C, T 5 =160°C, T 6 =165°C, the speed of the twin-screw extruder is R=300r·min -1 ; Afterwards, extrude, cool, and granulate to obtain materials for fully degradable insec...

Embodiment 3

[0055] Diatomaceous earth powder was completely soaked in Artemisia chrysanthemum oil, ultrasonically oscillated for 8 hours, filtered, and dried to obtain diatomite powder loaded with Artemisia chrysanthemum oil. Then disperse the powder in the glycerin solution of polyvinyl alcohol, and then spray the mixture into an inert hot air flow to make the droplets shrink into a spherical shape, and then dry them to obtain Artemisia chrysanthemum oil microcapsules.

[0056] Mix 60 parts by mass of poly PBAT, 10 parts by mass of polylactic acid, 10 parts by mass of cornstarch, 5 parts by mass of propylene glycol, 10 parts by mass of Artemisia chrysanthemum oil microcapsules and 5 parts by mass of light calcium carbonate in a high-speed mixer, and then The mixture is mixed in the twin-screw extruder, and the temperature of each section of the twin-screw extruder is set to T 1 =145°C, T 2 =155℃, T 3 =160°C, T 4 =160°C, T 5 =165°C, T 6 =165°C, the speed of the twin-screw extruder is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com