Treatment method for circulating water sewerage and reverse osmosis concentrated water and equipment thereof

A technology for reverse osmosis concentrated water and a treatment method, which is applied to the treatment method and equipment field of circulating water sewage and reverse osmosis concentrated water, and can solve adverse environmental effects, high inorganic salt content, and TDS that do not meet the discharge or reuse standards. and other problems, to achieve the effect of avoiding scaling and vulnerability, long running time, and stable running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

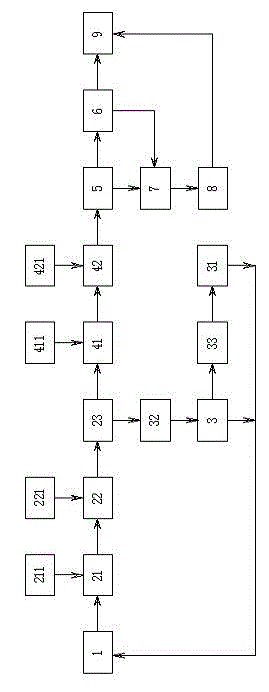

[0032] This embodiment takes the treatment of circulating water sewage and / or reverse osmosis concentrated water of a synthetic ammonia production enterprise as an example.

[0033] The equipment used in this embodiment includes waste water collection tank 1, softening sedimentation tank, sludge thickening tank, filter, nanofilter 5, electrodialysis device 6, concentrated water collection tank 7, evaporation crystallizer 8 and reuse water tank 9 ;

[0034] Described softening sedimentation tank comprises the first-level softening tank 21, the second-level softening tank 22 and the settling tank 23 connected successively; The water inlet of 21 links to each other with waste water collecting tank 1;

[0035] The sludge thickening tank is connected to the settling tank 23 through a sludge pump 32, and the sludge thickening tank 3 is equipped with a press filter 31 for sludge filtration; connected;

[0036] Described filter 4 comprises the multimedia filter 41 that links to eac...

Embodiment 3

[0058] This embodiment takes the treatment of reverse osmosis concentrated water produced by a coal-to-oil company as an example.

[0059] The equipment used in this embodiment is the same as that in Embodiment 1.

[0060] The circulating water sewage and reverse osmosis concentrated water to be treated in this embodiment have a TDS of about 8000mg / L, Ca 2+ About 1200mg / L, Mg 2+ About 860mg / L, COD about 90mg / L, and the treated water volume is 300t / h.

[0061] The method adopted in this embodiment includes the following steps:

[0062] (1) Softening and sedimentation: discharge the circulating water sewage and reverse osmosis concentrated water in the waste water collection tank 1 into the primary softening tank 21 at a flow rate of 300t / h, and pour the 25% lime water in the softening agent box 211 according to The amount of 1100l / h is added in the primary softening pool, and the waste water flows into the secondary softening pool 22 after 40min; the sodium carbonate with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com