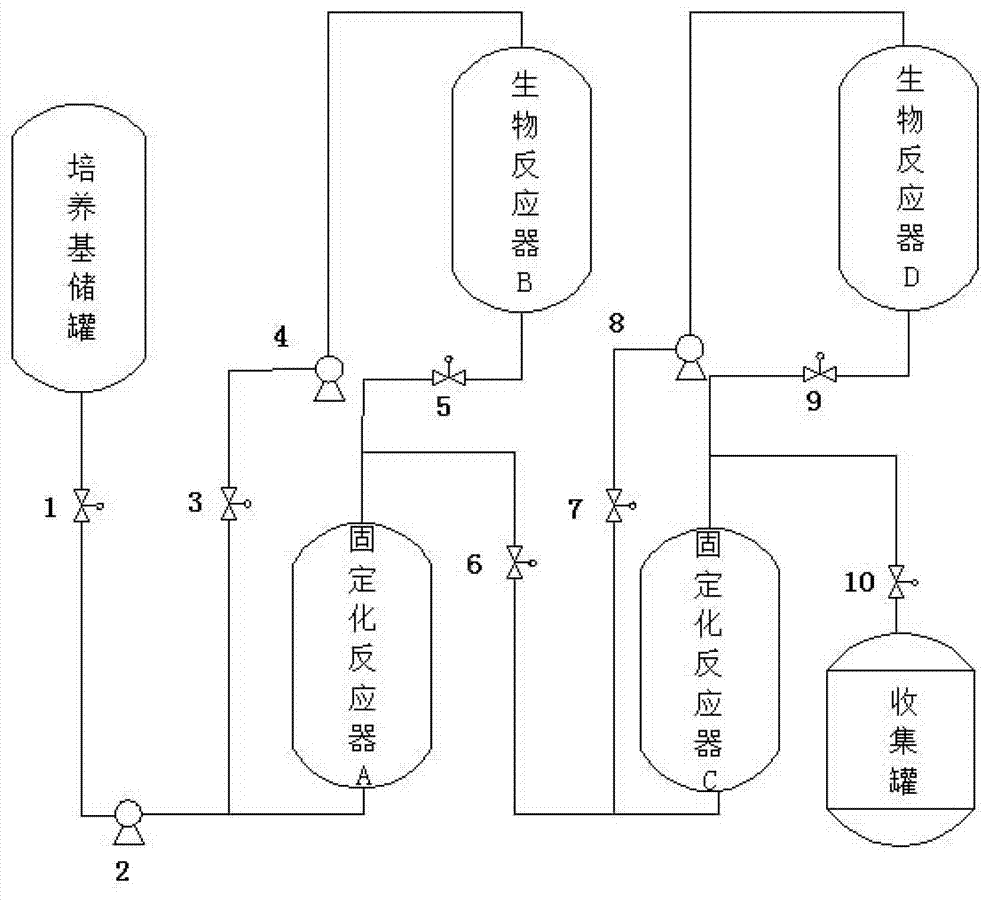

Apparatus and method for butanol production through dual bacteria immobilization anaerobic fermentation

A technology for anaerobic fermentation and butanol production, which is applied in the field of bioengineering, can solve the problems of low butanol yield, yield and ABE yield and yield, so as to shorten the fermentation cycle, improve the utilization rate, and improve the output per unit time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

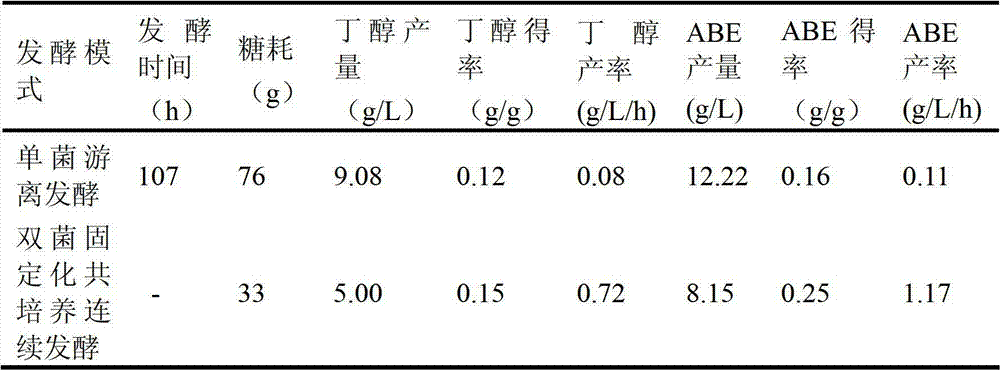

Embodiment 1

[0032] Bacterial species: Clostridium tyrobutyricum ATCC 25755 (Clostridium tyrobutyricum) is the butyric acid-producing bacteria, and Clostridium beijerinckii ATCC 55025 (Clostridium beijerinckii) is the butanol-producing bacteria.

[0033] Seed Medium:

[0034] Seed medium for Clostridium beijerinckii Ⅰ (CM 149) ( / L): Yeast extract 3g, beef extract 10g, peptone 10g, glucose 5g, soluble starch 1g, NaCl 5g, sodium acetate 3g, cysteine hydrochloride 0.5 g, carbon source and nitrogen source are sterilized separately, pH 6.8±0.2.

[0035] Clostridium tyrobutyricum seed medium II (RCM) ( / L): mineral 1 solution 40mL; mineral 2 solution 40mL, trace metal element solution 10mL, vitamin solution 10mL, 0.005%NiCl 6H 2 O10mL, 0.2%FeSO 4 ·7H 2 O 2mL, glucose 30g, peptone 5g, yeast extract 5g, NaCl 6g, cysteine-HCl 0.3g, 0.1% resazurin 0.5mL, boil in a boiling water bath to remove oxygen, carbon source and nitrogen source are sterilized separately , pH 6.0.

[0036] Above-mentioned...

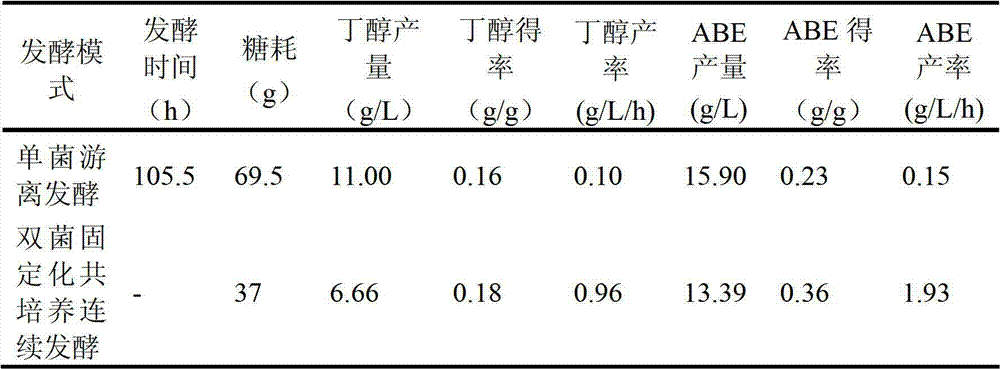

Embodiment 2

[0058] Bacterial species: Clostridium tyrobutyricum ATCC 25755 (Clostridium tyrobutyricum) is the butyric acid-producing bacterium, and Clostridium beijerinckiiATCC 55025 (Clostridium beijerinckii) is the butyric acid-producing bacterium.

[0059] Seed medium:

[0060] Seed medium for Clostridium beijerinckii Ⅰ (CM 149) ( / L): Yeast extract 3g, beef extract 10g, peptone 10g, glucose 5g, soluble starch 1g, NaCl 5g, sodium acetate 3g, cysteine hydrochloride 0.5 g, carbon source and nitrogen source are sterilized separately, pH 6.8±0.2.

[0061] Clostridium tyrobutyricum seed medium II (RCM) ( / L): mineral 1 solution 40mL; mineral 2 solution 40mL, trace metal element solution 10mL, vitamin solution 10mL, 0.005%NiCl 6H 2 O10mL, 0.2%FeSO 4 ·7H 2 O 2mL, glucose 30g, peptone 5g, yeast extract 5g, NaCl 6g, cysteine-HCl 0.3g, 0.1% resazurin 0.5mL, boil in a boiling water bath to remove oxygen, carbon source and nitrogen source are sterilized separately , pH 6.0.

[0062] Above-men...

Embodiment 3

[0079] Bacterial species: Clostridium tyrobutyricum ATCC 25755 (Clostridium tyrobutyricum) is the butyric acid-producing bacterium, and Clostridium tyrobutyricum ATCC 55025 (Clostridium beijerinckii) is the butanol-producing bacterium.

[0080] Seed medium:

[0081] Seed medium for Clostridium beijerinckii Ⅰ (CM 149) ( / L): Yeast extract 3g, beef extract 10g, peptone 10g, glucose 5g, soluble starch 1g, NaCl 5g, sodium acetate 3g, cysteine hydrochloride 0.5 g, carbon source and nitrogen source are sterilized separately, pH 6.8±0.2.

[0082] Clostridium tyrobutyricum seed medium II (RCM) ( / L): mineral 1 solution 40mL; mineral 2 solution 40mL, trace metal element solution 10mL, vitamin solution 10mL, 0.005%NiCl 6H 2 O10mL, 0.2%FeSO 4 ·7H 2 O 2mL, glucose 30g, peptone 5g, yeast extract 5g, NaCl 6g, cysteine-HCl 0.3g, 0.1% resazurin 0.5mL, boil in a boiling water bath to remove oxygen, carbon source and nitrogen source are sterilized separately , pH 6.0.

[0083] Above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com