Method for preparing lamellar-form borate crystal material

A crystal material and morphology technology, applied in the field of preparation of boric acid crystal materials, can solve the problems of complex preparation process, harsh reaction conditions, and large environmental pollution, and achieve the effects of low preparation temperature, cheap raw materials, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Dissolve 1g of analytically pure borax and 0.2mL of 80% acetic acid in 50mL of distilled water to prepare a solution;

[0019] 2) Transfer the solution into a polytetrafluoroethylene-lined hydrothermal kettle, control the filling ratio to 70%, then put the reaction kettle into a constant temperature reactor, control the temperature at 80°C, and react for 15 hours;

[0020] 3) After the reaction system is naturally cooled to room temperature, the product in the hydrothermal kettle is centrifuged and washed 3 to 8 times with distilled water and absolute ethanol. Dry in a vacuum drying oven to obtain a high-purity layered boric acid crystal material.

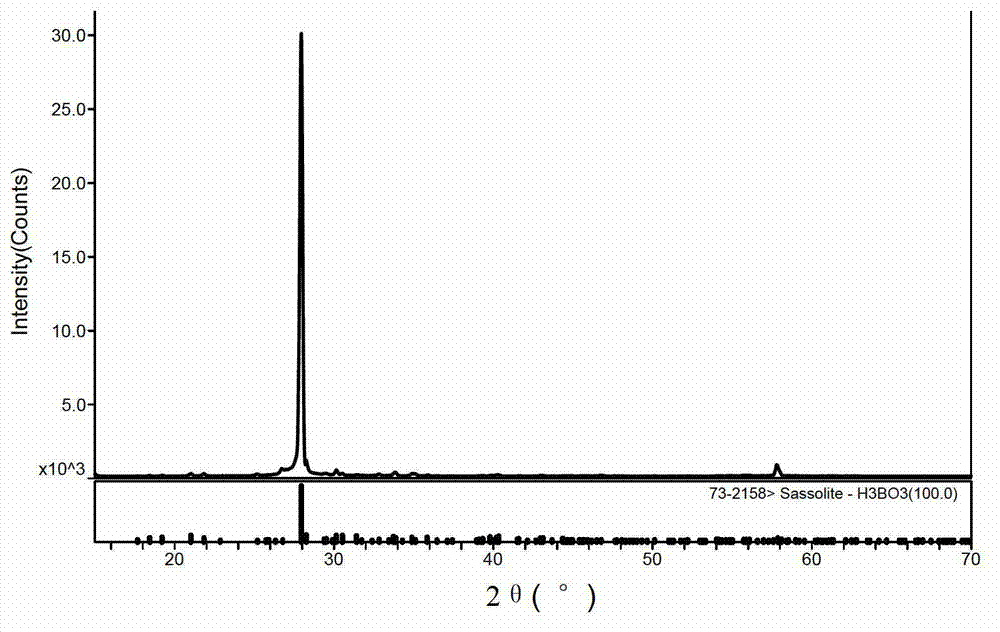

[0021] Depend on figure 1 And the standard card 73-2158 shows that the product is a high-purity boric acid boric acid crystal material, and its diffraction peak on the (002) crystal plane is extremely sharp, and the diffraction peak intensity is very large.

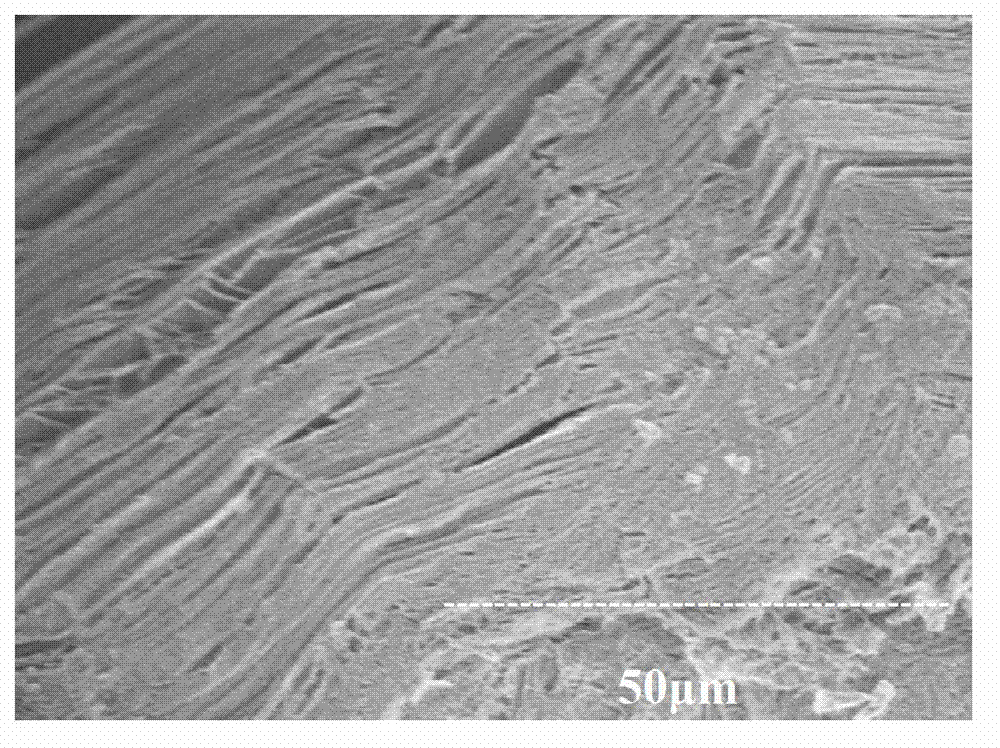

[0022] to combine figure 1 Depend on figure 2 It can be se...

Embodiment 2

[0024] 1) Dissolve 1 g of analytically pure borax and 0.5 mL of 80% acetic acid in 75 mL of distilled water to prepare a solution;

[0025] 2) Transfer the solution into a polytetrafluoroethylene-lined hydrothermal kettle, control the filling ratio to 60%, then put the reaction kettle into a constant temperature reactor, control the temperature at 120°C, and react for 9 hours;

[0026] 3) After the reaction system is naturally cooled to room temperature, the product in the hydrothermal kettle is centrifuged and washed 3 to 8 times with distilled water and absolute ethanol respectively, the centrifugal speed is 1200r / min, and the centrifugation time is 5min each time. Dry in a vacuum drying oven to obtain a high-purity layered boric acid crystal material.

Embodiment 3

[0028] 1) Dissolve 1 g of analytically pure borax and 0.8 mL of 80% acetic acid in 100 mL of distilled water to prepare a solution;

[0029] 2) Transfer the solution into a polytetrafluoroethylene-lined hydrothermal kettle, control the filling ratio to 50%, then put the reaction kettle into a constant temperature reactor, control the temperature at 160°C, and react for 4 hours;

[0030] 3) After the reaction system is naturally cooled to room temperature, the product in the hydrothermal kettle is centrifuged and washed 3 to 8 times with distilled water and absolute ethanol respectively, the centrifugation speed is 800r / min, and the centrifugation time is 3min each time, and finally the product is washed at 60°C. Dry in a vacuum drying oven to obtain a high-purity layered boric acid crystal material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com