High-temperature resistant aromatic polysulfonamide base lithium ion battery diaphragm

A polyarylsulfone amide-based, lithium-ion battery technology is applied to the application of the above-mentioned polyarylsulfone amide-based nanofiber membrane in lithium ion batteries, and the field of preparation of the above-mentioned polyarylsulfone amide-based nanofiber membrane can achieve heat resistance. Good, excellent flame retardant performance, uniform distribution of pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 30g of N,N-dimethylacetamide and 4.88g of polyarylsulfoneamide into a 100ml reagent bottle, and then stir at room temperature for 6h to obtain a uniform polyarylsulfoneamide solution (mass fraction: 14%). Another 1.0ml polyarylsulfone amide solution was taken out for electrospinning, the needle diameter was 1.6mm, the spinning voltage was 35kV, the height from the needle tip to the receiving plate was 12cm, the electrospinning time was 3h, and polyarylsulfone with a thickness of 60μm was obtained. Amide nanofiber membrane. Then the membrane was placed in a roller press with a pressure of 13 MPa to stay for 2 minutes to obtain a polyarylsulfonamide nanofiber membrane with a thickness of 30 μm.

Embodiment 2

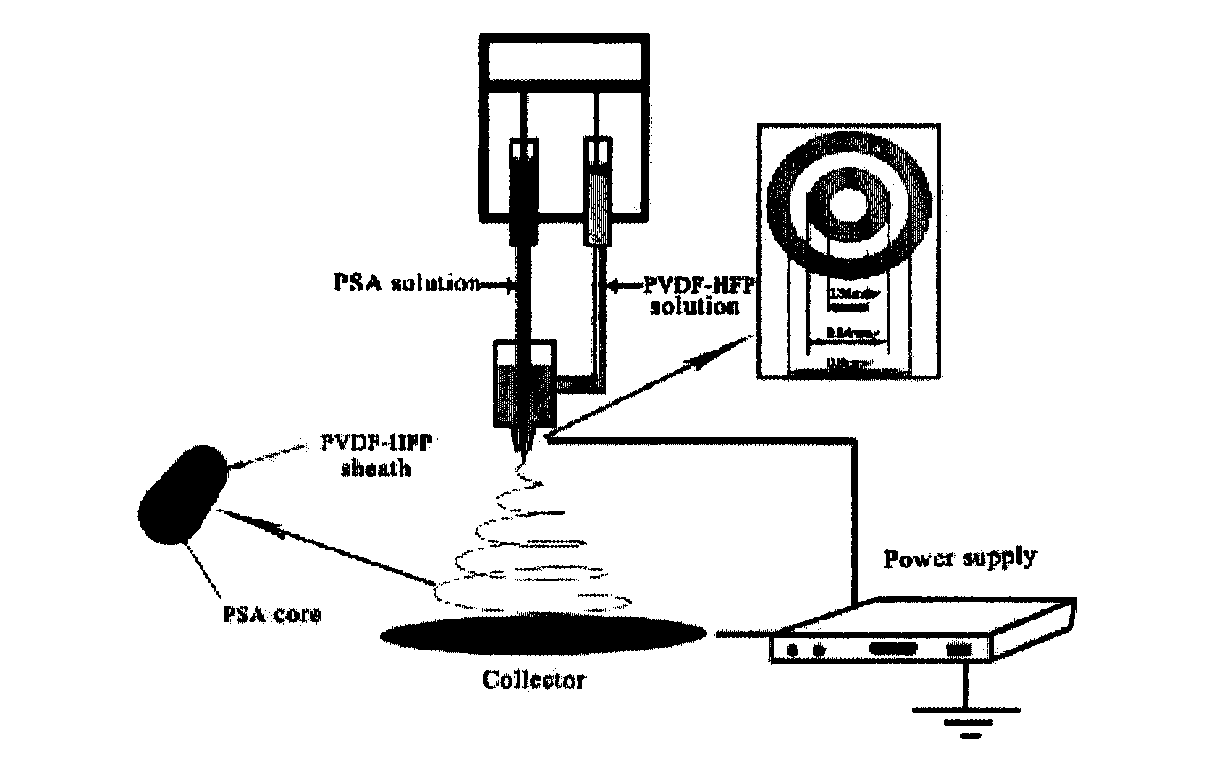

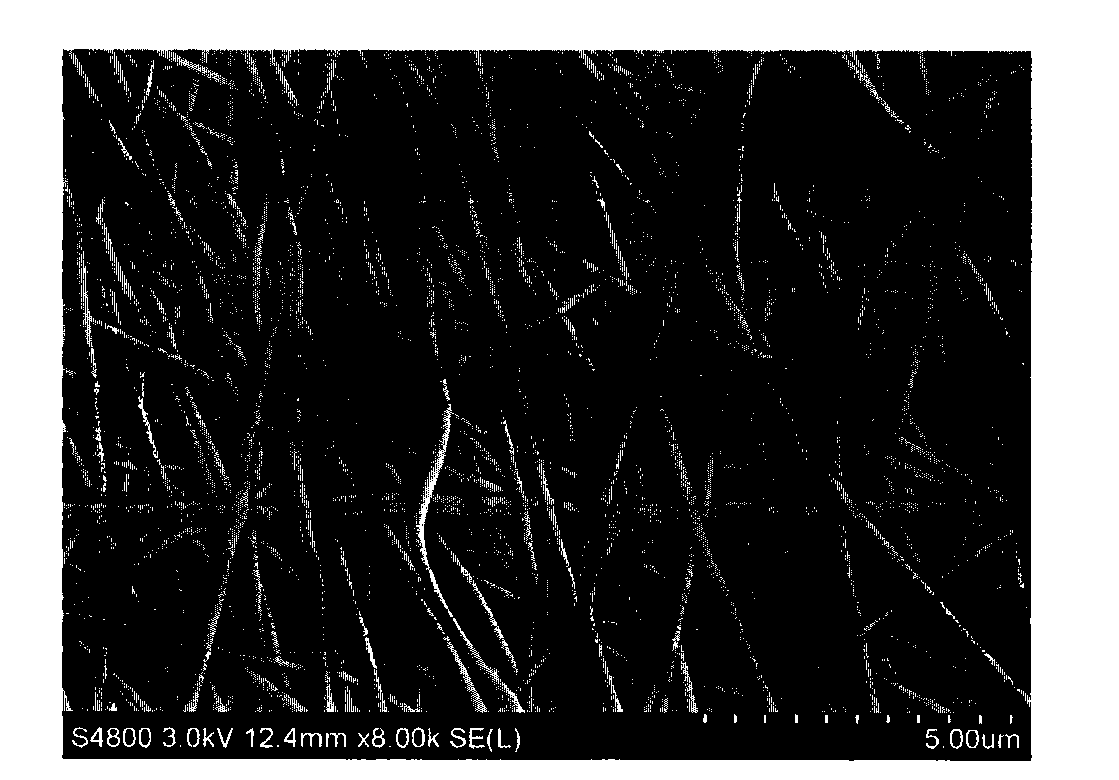

[0030] Add 4.88g of polyarylsulfoneamide and 10g of polyvinylidene fluoride-hexafluoropropylene into a 100ml reagent bottle, then add 30g of N,N-dimethylacetamide, and then stir at room temperature for 6h , to obtain a uniform polyarylsulfone amide solution (mass fraction is 14%) and polyvinylidene fluoride-hexafluoropropylene solution (mass fraction is 25%). In addition, 2ml of polyarylsulfoneamide solution and 2ml of polyvinylidene fluoride-hexafluoropropylene solution were taken out for coaxial electrospinning, the needle diameter was 0.34mm, the flow rate of spinning solution was 0.08ml / h, and the spinning voltage was 28kV. The height from the needle tip to the receiving plate was 12 cm, the electrospinning time was 5 h, and a polyarylsulfoneamide polyvinylidene fluoride-hexafluoropropylene nanofiber membrane with a thickness of 70 μm was obtained. Then the membrane was placed in a roller press with a pressure of 5 MPa to stay for 2 minutes to obtain a polyarylsulfoneamide...

Embodiment 3

[0032] Add 30g of dimethyl sulfoxide, 5.3g of polyarylsulfoneamide and 0.05g of nano silicon dioxide into a 100ml reagent bottle, then stir at room temperature for 8h to obtain a uniform polyarylsulfoneamide / nanometer silica Silicon solution (mass fraction is 27%). Another 2ml of polyarylsulfoneamide / nano-silica solution was taken out for electrospinning, the needle diameter was 1.6mm, the spinning voltage was 20kV, the height from the needle tip to the receiving plate was 12cm, the electrospinning time was 4h, and the obtained thickness was 80μm Polyarylsulfonamide / nanosilica nanofiber membrane. Then the membrane was placed in a roller press with a pressure of 8 MPa to stay for 2 minutes to obtain a polyarylsulfoneamide / nanometer silicon dioxide nanofiber membrane with a thickness of 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com