Silver phosphate/P25 bi-functional composite material, preparation method and application thereof

A composite material, dual-function technology, applied in the fields of botanical equipment and methods, applications, chemical instruments and methods, etc., can solve the problems of poor purification effect and singleness, and achieve low energy consumption, efficient degradation, and strong broad-spectrum bactericidal performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 300 mg of P25 in 40 ml of deionized water and sonicate for 30 minutes to obtain a P25 dispersion; weigh 1.529 g of silver nitrate and dissolve it in 20 ml of deionized water, and stir for 10 minutes to obtain a silver nitrate solution; Added dropwise to the P25 dispersion under the condition of , stirred slowly for 12 hours to form a mixed solution A; weighed 0.426 g Na 2 HPO 4 The solid was dissolved in 20 ml of deionized water, and dissolved by ultrasonic to obtain a disodium hydrogen phosphate solution; the prepared disodium hydrogen phosphate solution was added dropwise to the mixed solution A, and brownish yellow turbidity appeared in the reaction system, and after the addition was completed, The mixed solution was stirred continuously for 30 minutes, and the obtained product was vacuum-dried after repeated washing with absolute ethanol and deionized water several times after suction filtration.

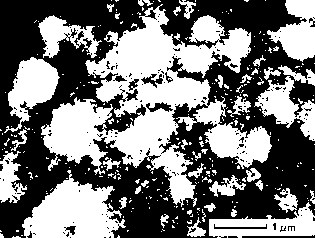

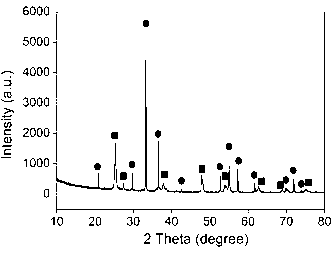

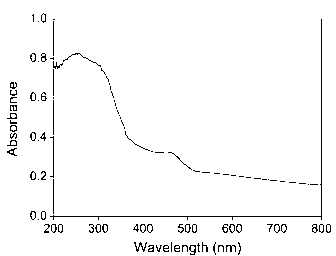

[0025] figure 1 For the scanning electron micrograph of ...

Embodiment 2

[0027] Dissolve 400 mg of P25 in 40 ml of deionized water and sonicate for 30 minutes to obtain a P25 dispersion; weigh 1.529 g of silver nitrate and dissolve it in 20 ml of deionized water, and stir for 10 minutes to obtain a silver nitrate solution; Add dropwise into the P25 dispersion under stirring conditions, and stir slowly for 12 hours to form a mixed solution A; weigh 0.426 g Na 2 HPO 4 Dissolve the solid in 20 ml of deionized water, and obtain a disodium hydrogen phosphate solution after ultrasonic dissolution, and then add the prepared disodium hydrogen phosphate solution dropwise into the mixed solution A, and brownish yellow turbidity appears in the reaction system; after the addition is completed The obtained mixed solution was continuously stirred for 60 minutes, and the obtained product was suction-filtered, washed repeatedly with absolute ethanol and deionized water for several times, and then vacuum-dried.

Embodiment 3

[0029] Dissolve 800 mg of P25 in 40 ml of deionized water and sonicate for 30 minutes to obtain a P25 dispersion; weigh 1.529 g of silver nitrate and dissolve it in 20 ml of deionized water, and stir for 10 minutes to obtain a silver nitrate solution; Add dropwise into the P25 dispersion under stirring conditions, and stir slowly for 12 hours to form a mixed solution A; weigh 0.426 g Na 2 HPO 4 Dissolve the solid in 20 ml of deionized water, and obtain a disodium hydrogen phosphate solution after ultrasonic dissolution, and then add the prepared disodium hydrogen phosphate solution dropwise into the mixed solution A, and brownish yellow turbidity appears in the reaction system; after the addition is completed The obtained mixed solution was continuously stirred for 45 minutes, and the obtained product was suction-filtered, washed repeatedly with absolute ethanol and deionized water for several times, and then vacuum-dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com