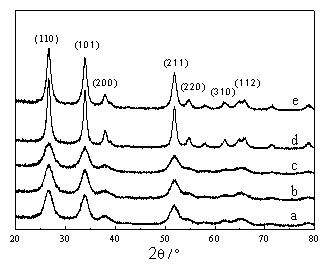

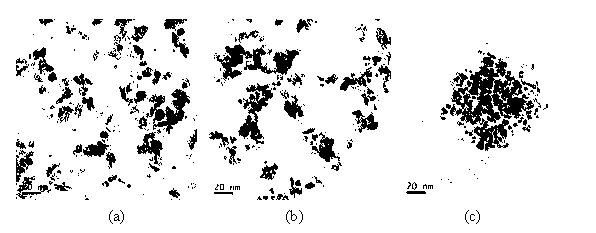

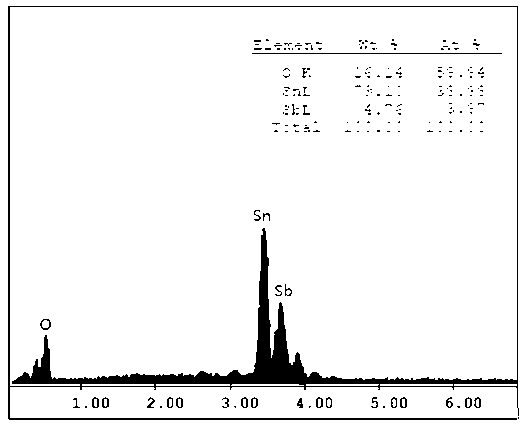

Method for preparing stibium doped stannic oxide nano-powder

A technology of antimony-doped tin oxide and nanopowder, which is applied in tin oxide, nanotechnology, nanotechnology, etc., can solve the problems of high powder resistance, uneven dopant dispersion, and large particle size impurities, and achieve excellent electrical resistance. properties, uniform dopant distribution, and small particle size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Weigh 3.506g SnC1 4 ·5H 2 O and 0.114g SbC1 3 (The molar ratio of Sb and Sn is 5:100), 50mL of absolute ethanol was added to a round bottom flask, 1ml of polyethylene glycol 400 was added, agate beads of a certain proportion were added, and ultrasonic waves were used for five minutes to make Mix evenly to obtain a mixed solution;

[0020] (2) Fix the round bottom flask on the rotary reactor, control the rotation speed at 15rad / min, and the temperature at 30°C. After stabilization, turn on the ammonia gas generator, control the flow rate of ammonia gas at 5ml / min, and transport the ammonia gas to the mixing tank through the pipeline. At the solution interface, after 1.5 hours, the mixed solution began to have a colorless, transparent, and white turbid emulsion. After continuing to react for 1 hour, stop filling the ammonia gas. After 10 minutes, increase the reaction temperature to 50°C and continue the reaction for 5 minutes, and fill the other interface with air...

Embodiment 2

[0024] Weigh 3.506g SnC1 4 ·5H 2 O and 0.114g SbC1 3 (The molar ratio of Sb and Sn is 5:100), add in 50mL absolute ethanol, weigh 1ml polyethylene glycol 400 again, disperse 5min under ultrasonic condition, make it mix uniformly, obtain mixed solution; Steps (2) and (3) of 1 obtained a white powder; the resulting white powder was calcined at 600 °C for 2 h to obtain light blue nano-Sb doped SnO 2 Particles, labeled 5%Sb-SnO 2 -600°C.

Embodiment 3

[0026] (1) Weigh 3.506g SnC1 4 ·5H 2 O and 0.228g SbC1 3 (The molar ratio of Sb and Sn is 10:100), 50 mL of absolute ethanol is added in a round-bottomed flask, 2ml of polyethylene glycol 400 is added, agate beads of a certain size are added, and the ultrasonic wave is ultrasonicated for five minutes, to disperse evenly;

[0027] (2) Fix the round-bottom flask on the rotary reactor, control the rotation speed to 30rad / min, and the temperature to 30°C. After stabilization, turn on the ammonia gas generator, control the flow rate of ammonia gas to 10ml / min, and transport the ammonia gas to the solution through the pipeline Interface, after 1.5 hours, the mixed solution began to have a colorless, transparent and white turbid emulsion. After continuing the reaction for 1 hour, stop filling the ammonia gas, stop the reaction after 10 minutes, raise the reaction temperature to 50°C for 5 minutes, and fill the other interface with air. Purify the ammonia in the device;

[0028] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com