Preparation method of modified carboxyl-terminated hyperbranched polyester resin and coating containing resin

A hyperbranched polyester and carboxyl-terminated technology, which is applied in the field of polyester resin, can solve the problems of inconvenient and quick use, cracking, poor flexibility, etc., and achieve high heat resistance, good flexibility, good heat resistance and flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

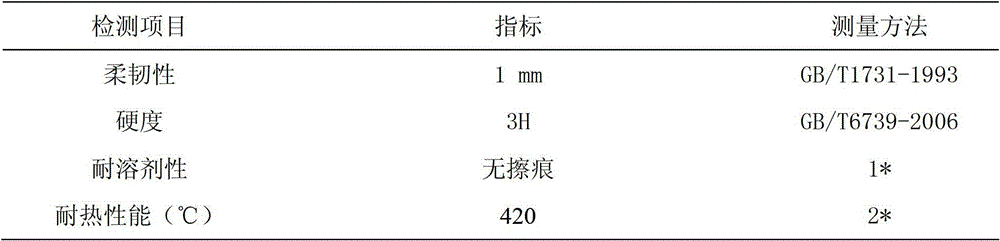

Embodiment 1

[0036] 1) Preparation of modified carboxyl-terminated hyperbranched polyester resin

[0037] a) Composition:

[0038] Diol: neopentyl glycol 104g (1mol);

[0039] Tribasic acid: 1,3,5-benzenetricarboxylic acid 210g (1mmol)

[0040] Silanol: Shin-Etsu KR220L 5.2g

[0041] Xylene: 2.08g

[0042]Silicone oligomer: Shin-Etsu silicone resin KR150 156g

[0043] Epoxy resin: Dicyclopentadiene dioxide 10g;

[0044] Crosslinking catalyst: tetrabutyl titanate 1.04g;

[0045] Organic solvent: propylene glycol methyl ether acetate 300g;

[0046] b) Synthesis steps:

[0047] Mix the dihydric alcohol and tribasic acid evenly, heat to 70°C, add silanol and xylene; after heating at 180°C for 1 h, heat up to 240°C, and heat for 1 h; cool down to 90°C, add 1.0% of the weight of trihydric alcohol times of organic solvent, organosilicon oligomer, epoxy resin and cross-linking catalyst; heated to 110 °C for 2 h; cooled to 90 °C, and finally added the remaining organic solvent.

[0048] c)...

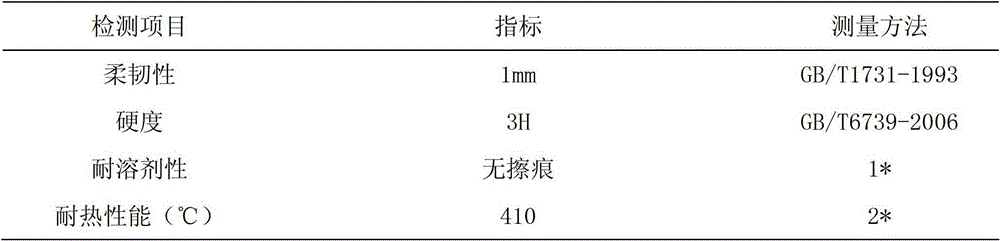

Embodiment 2

[0065] 1) Preparation of modified carboxyl-terminated hyperbranched polyester resin

[0066] a) Composition:

[0067] Diol: neopentyl glycol 62.4g (0.6mol); 2-methyl-1,3 propanediol 36g (0.4mol);

[0068] Tribasic acid: 1,2,4-benzenetricarboxylic acid 210g (1.0mol), 1,3,5-benzenetricarboxylic acid 105g (0.5mol) Silanol: heptapoly(cyclopentyl)silsesquioxane trisilicon Alcohol 4.84g, Heptaisobutylsilsesquioxane trisilanol 5.0g Xylene: 9.84g

[0069] Silicone oligomer: Shin-Etsu silicone resin KR150 100g, Shin-Etsu KR21247.6g

[0070] Epoxy resin: trimethylolpropane glycidyl ether 49.2g;

[0071] Crosslinking catalyst: tetrabutyl titanate 4.9g

[0072] Organic solvent: 147 g of propylene glycol methyl ether acetate, 23 g of butanol

[0073] b) Synthesis steps:

[0074] Mix the dihydric alcohol and tribasic acid evenly, heat to 90°C, add silanol and xylene; after heating at 200°C for 3h, heat up to 220°C, and heat for 2h; cool down to 90°C, add propylene glycol methyl ether ...

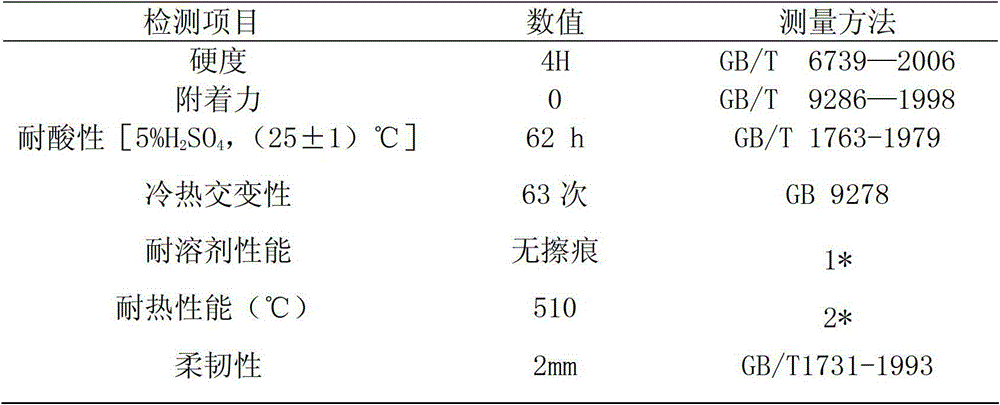

Embodiment 3

[0090] 1) Preparation of hydroxy silicone oil

[0091] a) Recipe

[0092] Octamethylcyclotetrasiloxane: 200g

[0093] Tetramethylammonium hydroxide: 0.02g

[0094] Water: 7.4g

[0095] DMF: 60g

[0096] b) Preparation process

[0097] In a reactor equipped with a condenser, a thermometer, a dropping funnel and a stirrer, add octamethylcyclotetrasiloxane, tetramethylammonium hydroxide and DMF in sequence according to the proportions, start stirring and heat up, and heat up to 90°C After the temperature was kept constant, distilled water was added dropwise with stirring. After the dropwise addition was completed, the reaction was performed at a constant temperature for 9.5 hours, then the temperature was raised to 150 °C for 1 hour, and the temperature was lowered to 80 °C. The vacuum distillation was started, and the pressure was controlled at 0.06 MPa, and the reaction was evaporated. The small molecules produced in the process were cooled to room temperature, and the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com