Weakly acidic transparent soap and preparation method thereof

A transparent soap, weak acid technology, applied in chemical instruments and methods, surface active non-soap compounds and detergent compositions, preparations for skin care, etc., can solve the problems of easy formation of soap scum, high pH value, high irritation , to achieve the effect of no residue, acid-base balance, no tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

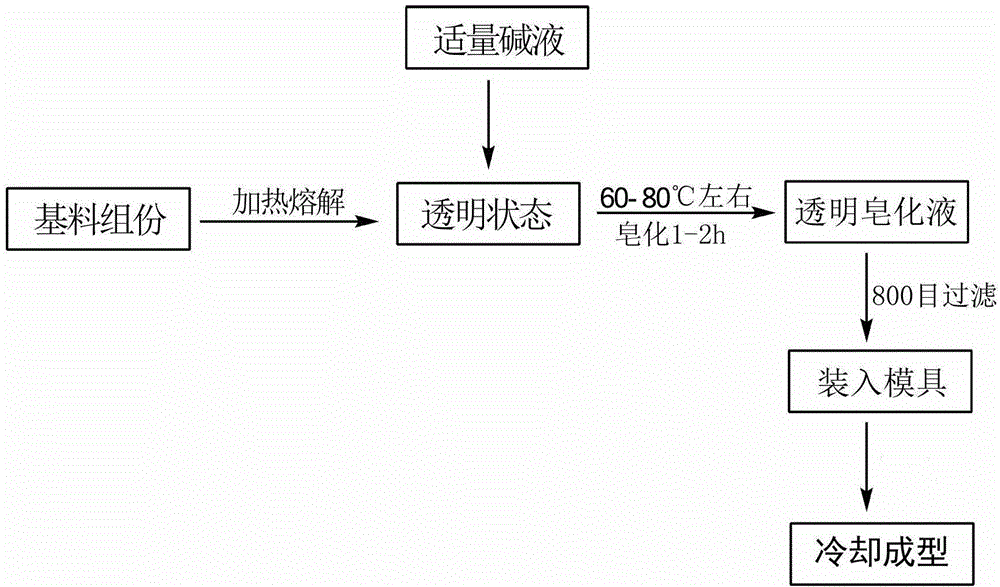

Method used

Image

Examples

Embodiment 1

[0040] The weakly acidic transparent soap composition of the present embodiment, its raw material composition by weight percentage is:

[0041] N-Cocoyl-L-Glutamic Acid 30.0%

[0042] Propylene Glycol 10.0%

[0043] Glycerin 5.0%

[0044] Lemon Yellow 0.01%

[0045] Fragrance 0.2%

[0046] Preservatives 0.3%

[0047] Triethanolamine Adjust the pH to 5.5-6.5

[0048] Deionized water balance

[0049] The production method of the weakly acidic transparent soap of the present embodiment is as follows: Weigh the amounts of each component in proportion, disperse N-cocoyl-L-glutamic acid in propylene glycol and glycerin, and slowly heat to melt and become transparent while stirring. Add the pre-prepared triethanolamine solution, adjust the pH value of the reaction solution to 5.5-6.5, after the addition is complete, continue to heat up to about 65°C, and keep it for 1.5h, so that N-cocoyl-L-glutamic acid and three Ethanolamine fully reacts to obtain a completely transparent sa...

Embodiment 2

[0051] The weakly acidic transparent soap composition of the present embodiment, its raw material composition by weight percentage is:

[0052] N-Cocoyl-L-Glutamic Acid 35.0%

[0053] Propylene Glycol 12.0%

[0054] Glycerin 10.0%

[0055] Plant additives 6.0%

[0056] Lemon Yellow 0.01%

[0057] Fragrance 0.2%

[0058] Preservatives 0.3%

[0059] Triethanolamine Adjust the pH to 5.0-6.5

[0060] Deionized water balance

[0061] The plant additive consists of 5 parts by weight of aloe extract, 2 parts by weight of witch hazel extract, 3 parts by weight of oat extract, 4 parts by weight of ginger extract, 4 parts by weight of rose extract, and 3 parts by weight of lavender extract. It consists of 4 parts by weight of cucumber extract, 3 parts by weight of tea extract, 1 part by weight of angelica extract, 2 parts by weight of ginseng extract, 4 parts by weight of chamomile extract and 4 parts by weight of seaweed extract.

[0062] The production method of the weakly aci...

Embodiment 3

[0064] N-Cocoyl-L-Glutamic Acid 40.0%

[0065] Propylene Glycol 10.0%

[0066] Glycerin 10.0%

[0067] Sucrose 8.0%

[0068] Ethanol 3.0%

[0069] Plant additives 6.0%

[0070] Potassium hydroxide to adjust the pH to 5.0-6.5

[0071] Deionized water balance

[0072] The plant additive is composed of 1 part by weight of aloe extract, 1 part by weight of witch hazel extract, 1 part by weight of ginger extract, 1 part by weight of rose extract, 1 part by weight of lavender extract and 1 part by weight of cucumber extract .

[0073] The production method of the weakly acidic transparent soap of the present embodiment is as follows: take the amount of each component in proportion, disperse N-cocoyl-L-glutamic acid and sucrose in propylene glycol and glycerin, and slowly heat to melt and become transparent while stirring . Add the pre-prepared potassium hydroxide solution to adjust the pH value of the reaction solution to 5.0-6.5. After the addition is complete, continue to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com