Method for extracting ginsenoside

A technology of ginsenoside and extraction method, which is applied in the field of medicine, can solve the problems of loss of active ingredients, decomposition, and high content of impurities in products, and achieve the effects of being suitable for industrial production, maintaining biological activity, and improving extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

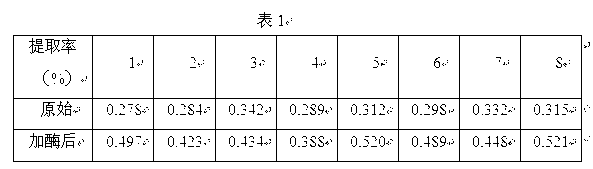

Examples

Embodiment 1

[0023] a. Crush the ginseng raw materials, pass through a 40-mesh sieve, and then put them into the extraction tank;

[0024] b. Add laccase into the extraction tank, the weight-volume ratio of ginseng powder to the crude enzyme extract is 1kg:10L, enzymatically hydrolyze at 60°C for 2h, filter with 200 mesh filter cloth;

[0025] c. Add methanol to the filter residue, the weight-volume ratio of the filter residue to methanol is 1kg:100L, after soaking for 0.5h, supplemented with microwave action for 3min, microwave power is 300W, continue to extract for 1h, filter, the filtrate is concentrated under reduced pressure, and dried The crude ginsenoside is obtained.

Embodiment 2

[0027] a. Crush the ginseng raw materials, pass through a 40-mesh sieve, and then put them into the extraction tank;

[0028] b. Add lignin peroxidase to the extraction tank, the weight-volume ratio of ginseng powder to the crude enzyme extract is 1kg:20L, enzymatically hydrolyze at 60°C for 1 hour, and filter with 200 mesh filter cloth;

[0029] c. Add ethanol to the filter residue, the weight-volume ratio of the filter residue to ethanol is 1kg:150L, after soaking for 0.5h, supplemented with microwave action for 3min, microwave power is 300W, continue to extract for 1.5h, filter, concentrate the filtrate under reduced pressure, and dry Then the crude ginsenoside was obtained.

Embodiment 3

[0031] a. Crush the ginseng raw materials, pass through a 40-mesh sieve, and then put them into the extraction tank;

[0032] b. Add manganese peroxidase into the extraction tank, the weight-volume ratio of ginseng powder to the crude enzyme extract is 1kg:50L, enzymatically hydrolyze at 0°C for 2h, filter with 200 mesh filter cloth;

[0033] c. Add methanol to the filter residue, the weight-volume ratio of the filter residue to methanol is 1kg:100L, after soaking for 0.5h, assisted by microwave action for 5min, the microwave power is 300W, continue to extract for 0.5h, filter, concentrate the filtrate under reduced pressure, and dry Then the crude ginsenoside was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grinding particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com