Method and device for synchronously removing sulfur dioxide and nitric oxide by flue gas biological method

A flue gas and biological method technology, applied in chemical instruments and methods, nitrogen preparation, separation methods, etc., can solve the problem of not taking into account the removal, and achieve the requirements of low intake air, cost saving, and water consumption reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

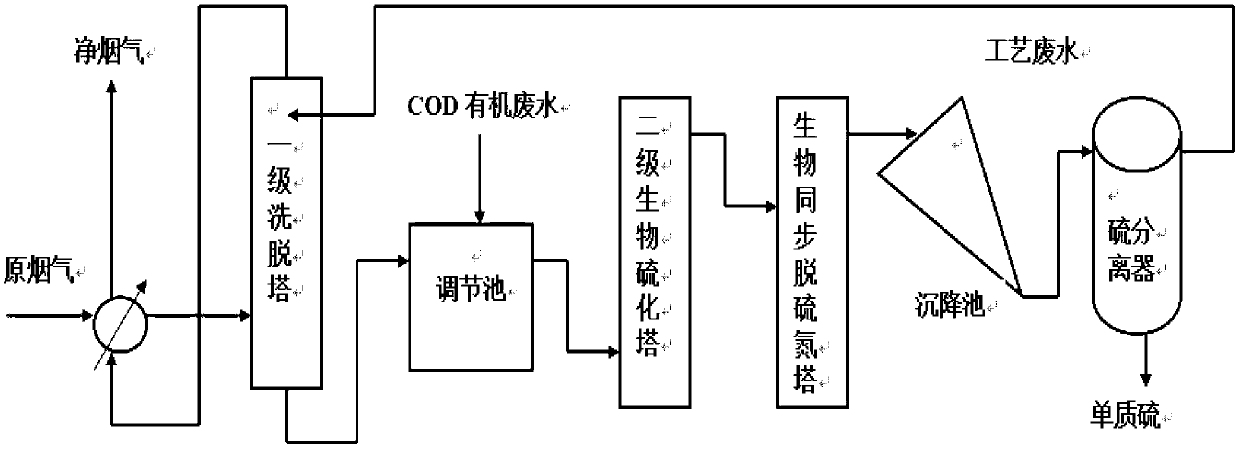

Embodiment 1

[0029] Example 1: The flue gas enters the elution tower after heat exchange, and within 2-3 seconds of the medium residence time, the pollutant SO in the gas phase is 2 / NO X Eluted down, so that after the purification treatment, the emission of gas reaches the standard (SO 2 / NO X≤100mg / Nm 3 ). The eluted waste liquid enters the regulating tank, and COD organic wastewater is added at the same time, and after homogenization, it enters the biosulfurization tower. The microorganisms mainly composed of sulfate-reducing bacteria are in an anaerobic environment with a pH value of 5-6 and a temperature of 25-30°C. , the SO in the liquid phase 4 2- / SO 3 2- Convert to S 2- / HS - . Then the wastewater mainly containing sulfide enters the biological desulfurization nitrogen tower, and the microorganisms mainly composed of Thiobacillus denitrification convert the desulfurization compound into elemental sulfur in an anaerobic environment with a pH value of 7-8 and a temperature...

Embodiment 2

[0030] Embodiment 2: The flue gas enters the elution tower after heat exchange, and the pollutant SO 2 / NO X Eluted down, so that after the purification treatment, the emission of gas reaches the standard (SO 2 / NO X ≤100mg / Nm 3 ). The eluted waste liquid enters the regulating tank, and COD organic wastewater is added at the same time, and after homogenization, it enters the biosulfurization tower. The microorganisms mainly composed of sulfate-reducing bacteria are in an anaerobic environment with a pH value of 6-7 and a temperature of 35-40°C. , the SO in the liquid phase 4 2- / SO 3 2- Convert to S 2- / HS - . Then the wastewater mainly containing sulfide enters the biological desulfurization nitrogen tower, and the microorganisms mainly composed of Thiobacillus denitrification convert the desulfurization compound into elemental sulfur in an anaerobic environment with a pH value of 6.5-7.5 and a temperature of 35-40°C. Nitrogen is turned into nitrogen gas and discha...

Embodiment 3

[0031] Embodiment 3: The flue gas enters the elution tower after heat exchange, and within 2-3 seconds in the medium residence time, the pollutant SO in the gas phase is 2 / NO X Eluted down, so that after the purification treatment, the emission of the gas reaches the standard (SO 2 / NO X ≤100mg / Nm 3 ). The eluted waste liquid enters the regulating tank, and COD organic wastewater is added at the same time, and after homogenization, it enters the biosulfurization tower. The microorganisms mainly composed of sulfate-reducing bacteria are in an anaerobic environment with a pH value of 5-7 and a temperature of 30-35°C. , the SO in the liquid phase 4 2- / SO 3 2- Convert to S 2- / HS - . Afterwards, the wastewater mainly composed of sulfides enters the biological desulfurization nitrogen tower, and the microorganisms mainly composed of Thiobacillus denitrification convert the desulfurized compounds into elemental sulfur in an anaerobic environment with a pH value of 6-7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com