Graphene and fabrication method thereof and super capacitor

A graphene and nanographite flake technology, applied in graphene, hybrid capacitor electrodes, nanocarbons, etc., can solve the problems of poor conductivity, low energy density of activated carbon, and low energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

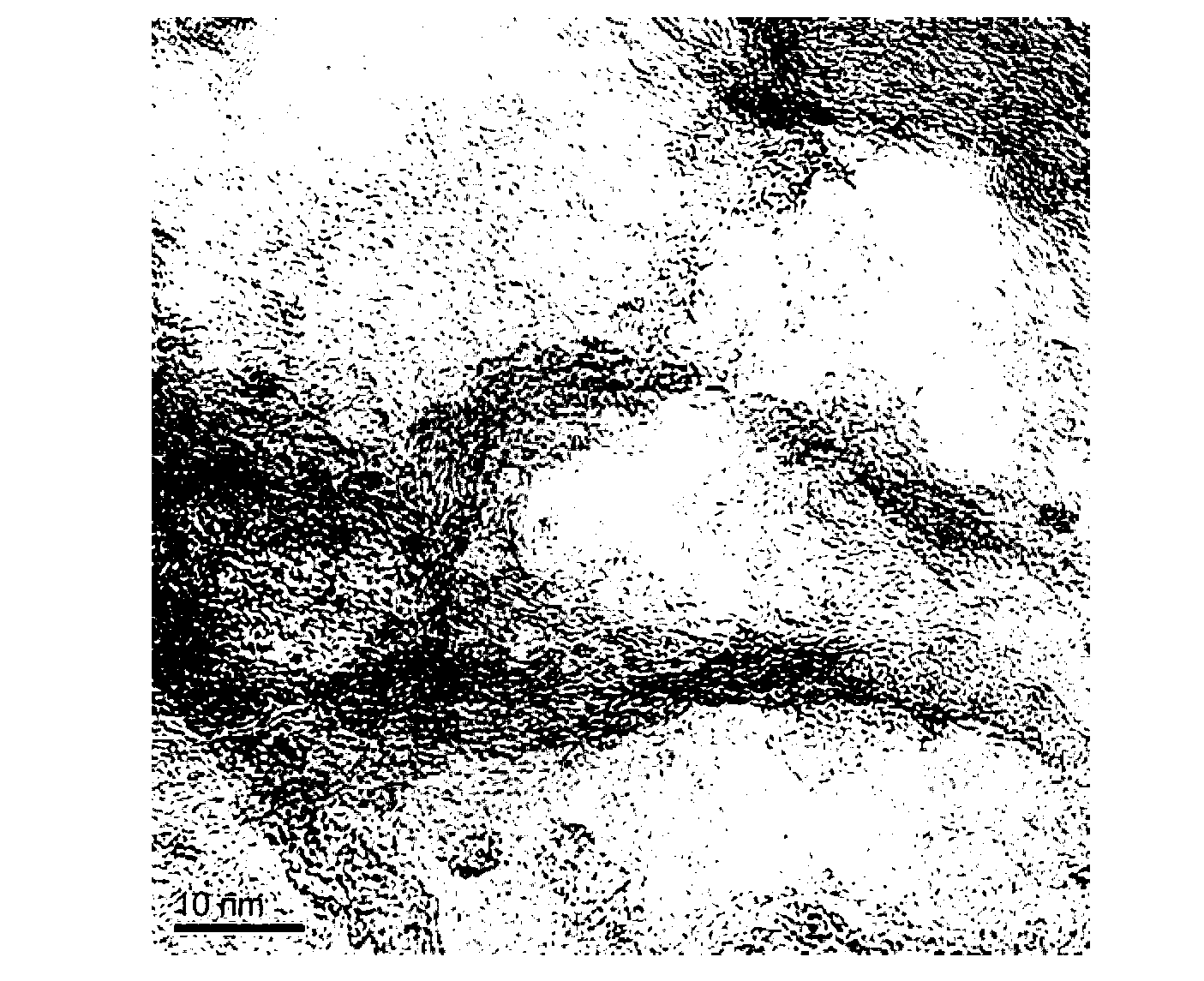

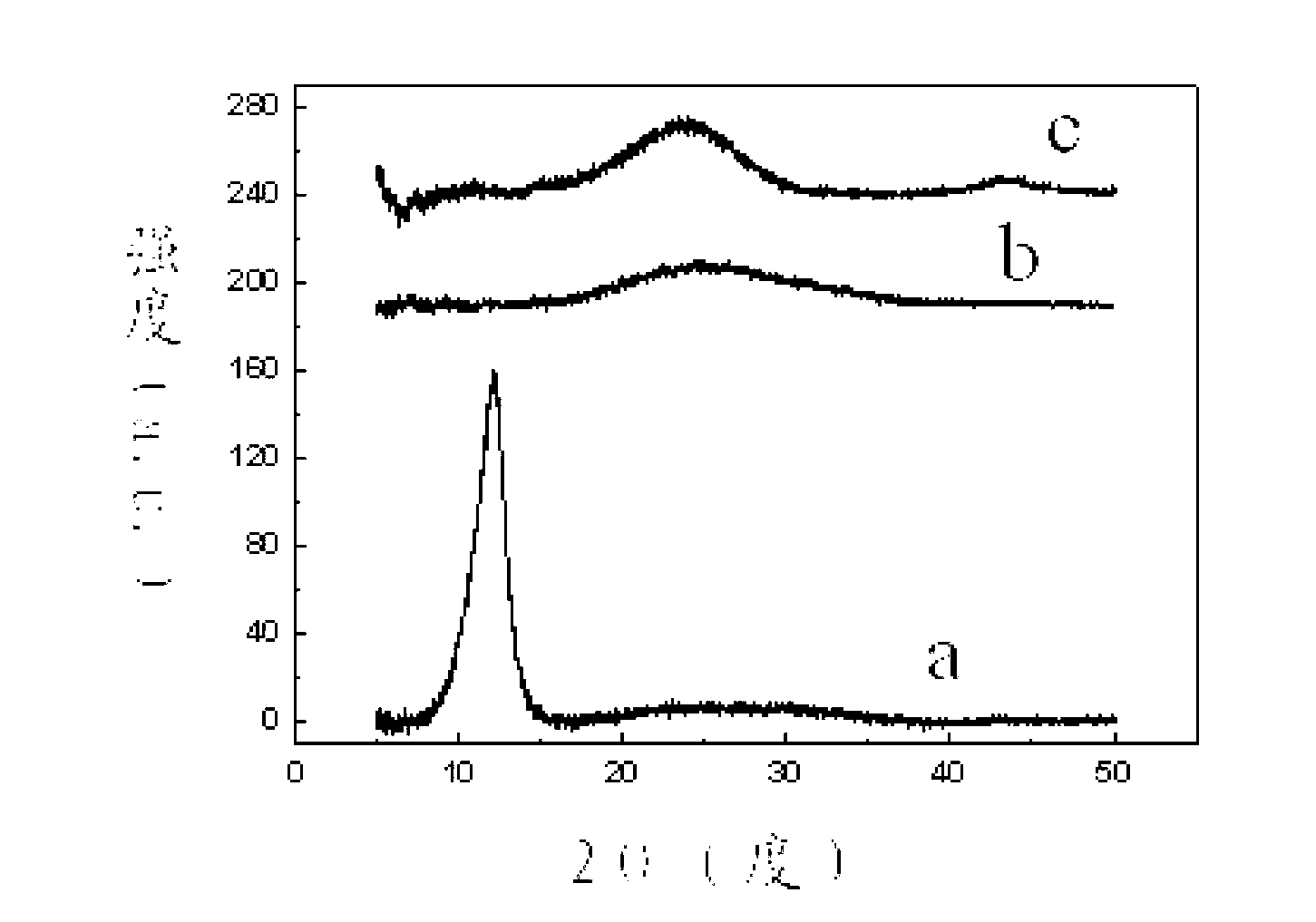

[0033] The invention provides a preparation method of graphene, comprising the following steps: A) ball milling expanded graphite to obtain nano-graphite flakes with a thickness of 15-200 nm; B) oxidizing the nano-graphene flakes to obtain partially oxidized Graphene; the carbon-to-oxygen ratio of the partially oxidized graphene is 20:1 to 3:1; C) mixing the partially oxidized graphene with a first activator, heating for the first pore forming to obtain micropores Graphene; D) The microporous graphene is mixed with a second activator, and heated to form holes for the second time to obtain graphene.

[0034] Wherein, the expanded graphite can be the expanded graphite well-known to those skilled in the art, and there is no special limitation. The expanded graphite in the present invention is preferably expanded graphite with a size of 50-300 μm, more preferably 100-200 μm. After the expanded graphite is ball milled, flake graphite with a nanometer thickness is obtained, and the...

Embodiment 1

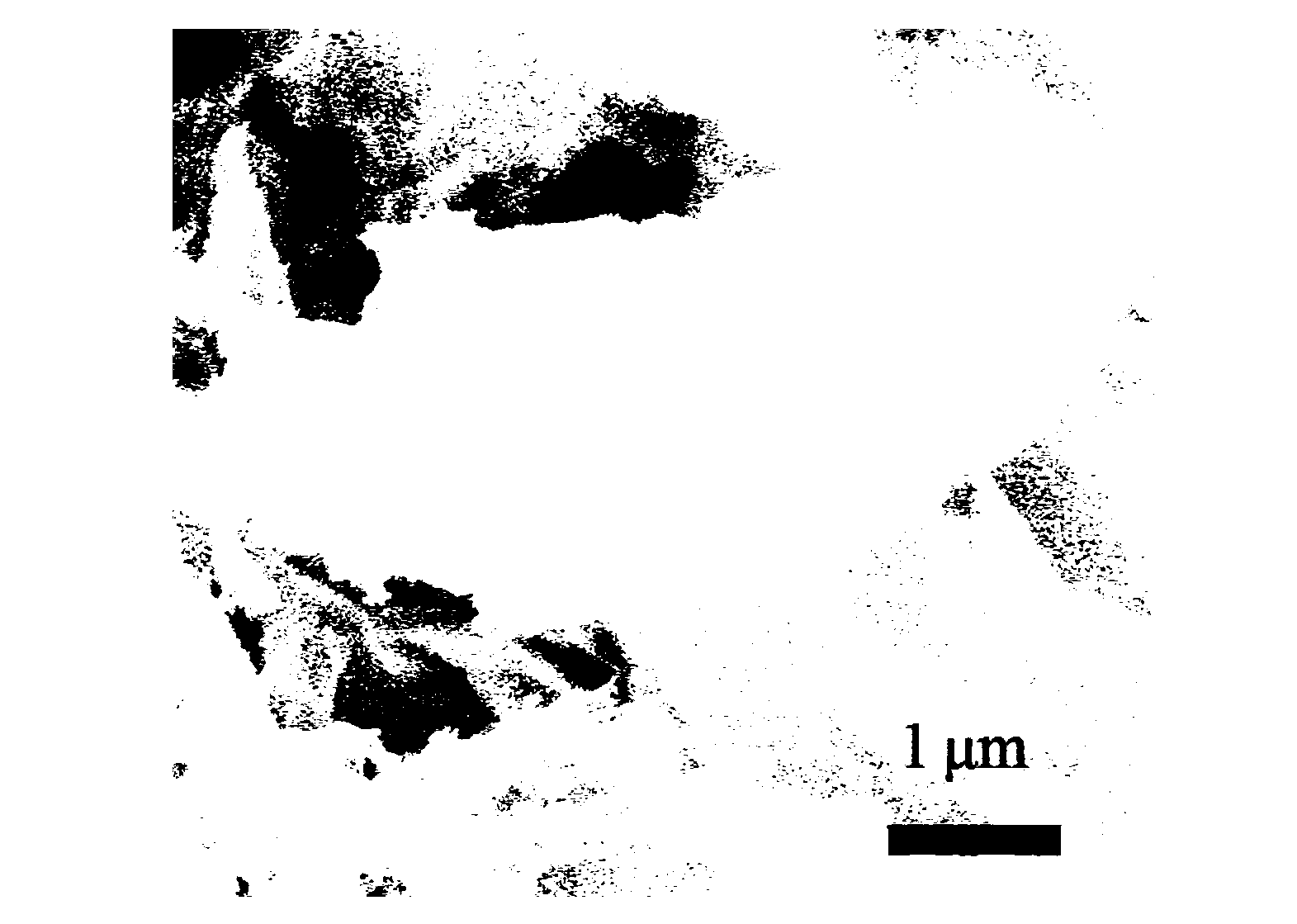

[0057] 1.1 Mill 5 g of expanded graphite with a size of 50 μm in a ball mill at 300 r / min for 5 hours to obtain graphite nanosheets with a thickness of 100 nm.

[0058] 1.2 Mix 5g of nano-graphite flakes obtained in 1.1, 87.5ml of concentrated hydrochloric acid and 45ml of concentrated nitric acid, then slowly add 45g of potassium chlorate, and react for 24 hours in an ice-water bath to obtain partially oxidized graphene, which is repeatedly washed with deionized water Wash to neutral pH.

[0059] 1.3 After fully impregnating 5g of partially oxidized graphene obtained in 1.2 in 0.5mol / L oxalic acid solution, heat it in a tube furnace to 500°C for low temperature expansion for 20s, and mix the expanded graphene with potassium hydroxide according to the mass After mixing evenly at a ratio of 1:6, heat to 600°C for 12 hours in a tube furnace containing water vapor and nitrogen atmosphere to obtain microporous graphene.

[0060] 1.4 After the microporous graphene obtained in 1.3 ...

Embodiment 2

[0072] 2.1 5 g of expanded graphite with a size of 50 μm was ball-milled for 24 hours in a ball mill under the condition of 200 r / min to obtain graphite nanosheets with a thickness of 15 nm.

[0073] 2.2 Mix 5g of nano-graphite flakes obtained in 2.1, 87.5ml of concentrated hydrochloric acid and 45ml of concentrated nitric acid, then slowly add 45g of sodium chlorate, and react for 48h under the condition of an ice-water bath to obtain partially oxidized graphene, which is deionized Water was washed repeatedly until the pH was neutral.

[0074] 2.3 After fully impregnating 5g of partially oxidized graphene obtained in 2.2 in 1mol / L oxalic acid solution, heat it in a tube furnace to 600°C for low temperature expansion for 30s, and mix the expanded graphene and potassium hydroxide according to the mass ratio After mixing evenly at a ratio of 1:8, heat to 900°C for 5 hours in a tube furnace containing water vapor and nitrogen atmosphere to obtain microporous graphene.

[0075] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com