Method for preparing nanometer-level cube-like cobaltosic oxide

A technology for cobalt tetroxide and cubes, which is applied in the field of preparing nano-scale cubic cobalt tetroxide, can solve the problems of complex synthesis process, difficulty in reaching nanometer scale, and difficulty in controlling particle morphology, and achieves simple preparation process, low price, and easy realization of large-scale preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

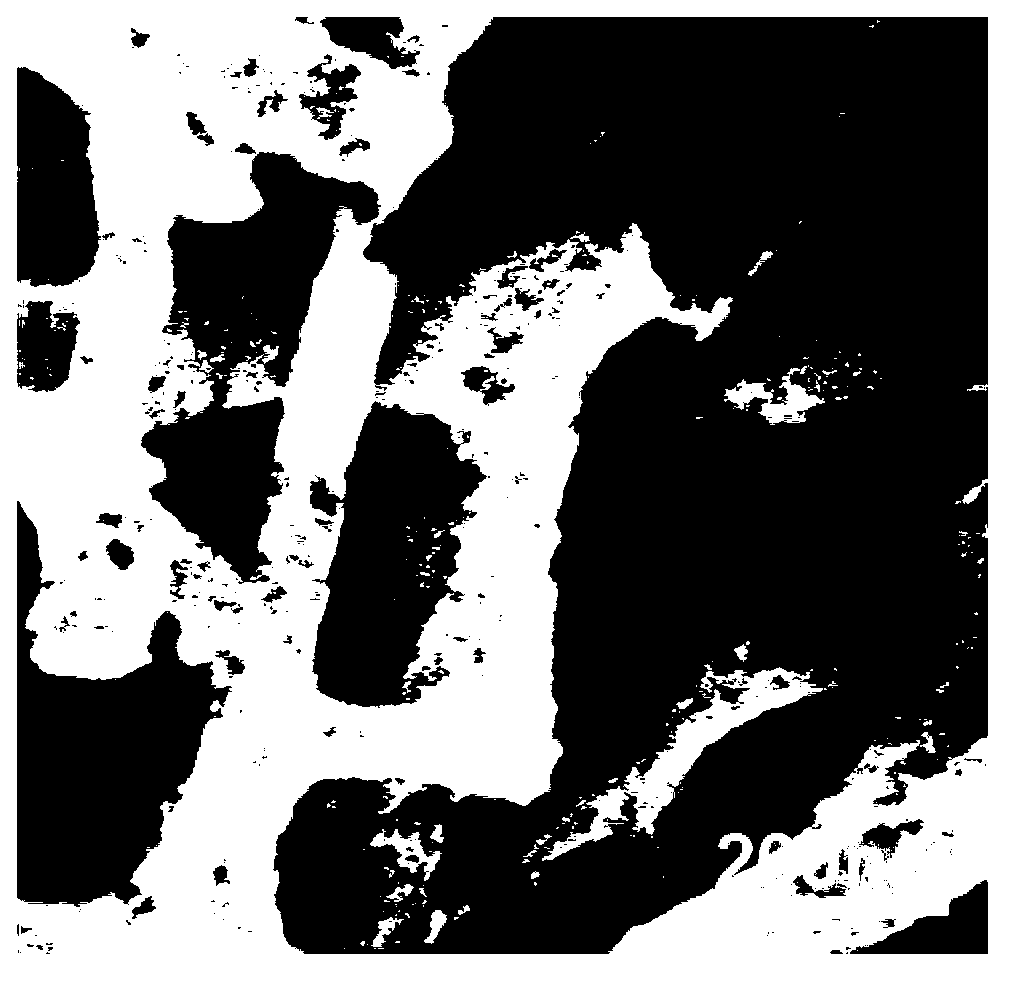

[0030] Disperse 0.3 g of dimethylglyoxime in 30 ml of absolute ethanol, and adjust the pH value of the dimethylglyoxime solution to 13.0 with 0.5 M sodium hydroxide ethanol solution. Dissolve 0.3 g of nickel chloride hexahydrate in 1 liter of water, and add the dimethylglyoxime solution dropwise into the nickel chloride solution under ultrasonic conditions to obtain a red flocculent substance. The above-mentioned red flocculent product was suction-filtered, washed and dried, and then calcined at 500°C for 1 h under Ar atmosphere to obtain a black powder. The nickel oxide and nickel in the black powder are etched away with 2.0mol / L hydrochloric acid to obtain nanostructured porous carbon, and its scanning electron microscope photo is as follows: figure 1 Shown:

Embodiment 2

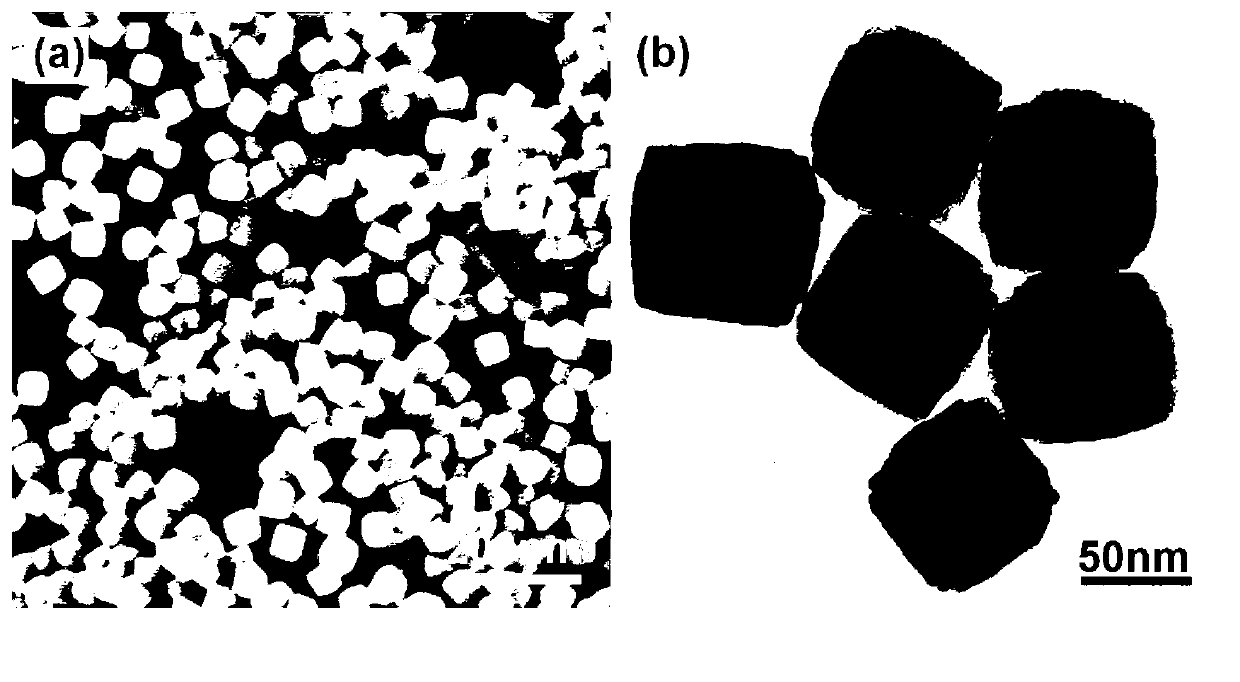

[0032] Add 0.3 mg of porous carbon to 40 ml of distilled water for ultrasonic dispersion, then add 28.0 mg of cobalt nitrate and 36.0 mg of urea, stir evenly, transfer to a 60 ml hydrothermal reaction kettle, react at 120 ° C for 12 hours, and naturally cool to room temperature Afterwards, after centrifugation and washing, nano-scale cubic cobalt tetroxide powder is obtained, and its scanning electron microscope and transmission electron microscope photos are as follows: figure 2 Shown:

Embodiment 3

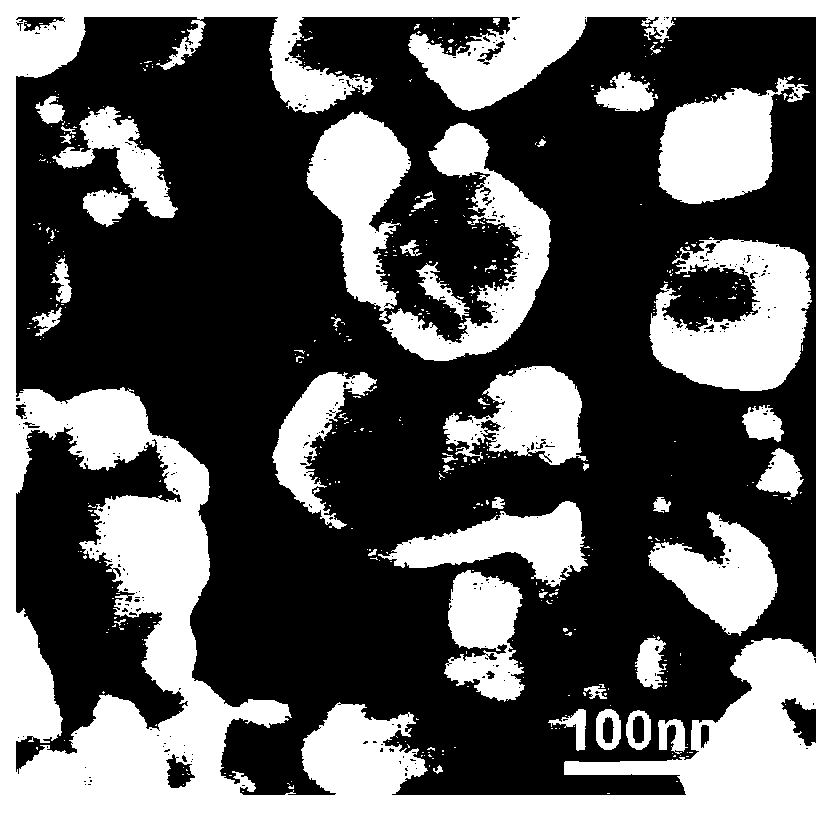

[0034] In the absence of porous carbon, add 28.0mg of cobalt nitrate and 36.0mg of urea to 40ml of distilled water, stir evenly, transfer to a 60ml hydrothermal reaction kettle, react at 120°C for 12 hours, cool to room temperature naturally, and centrifuge After separation and washing, cobalt trioxide powder of irregular shape is obtained, and its scanning electron microscope photo is as follows: image 3 Shown:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com