Titanium-tungsten alloy oxide nano-tube electrode with characteristic of in-situ vertical growth, preparation method and applications thereof

A titanium-tungsten alloy, vertical growth technology, applied in the field of pollution control and material chemistry, can solve the problems of weakening the catalytic performance of photocatalysts, easy to fall off from the body, small specific surface area of the coating film, etc., to enhance the photocatalytic performance and increase the scope of use , the effect of efficient catalytic degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation and characterization of a titanium-tungsten alloy oxide nanotube array for efficient photoelectric degradation of organic pollutants, which specifically includes the following steps:

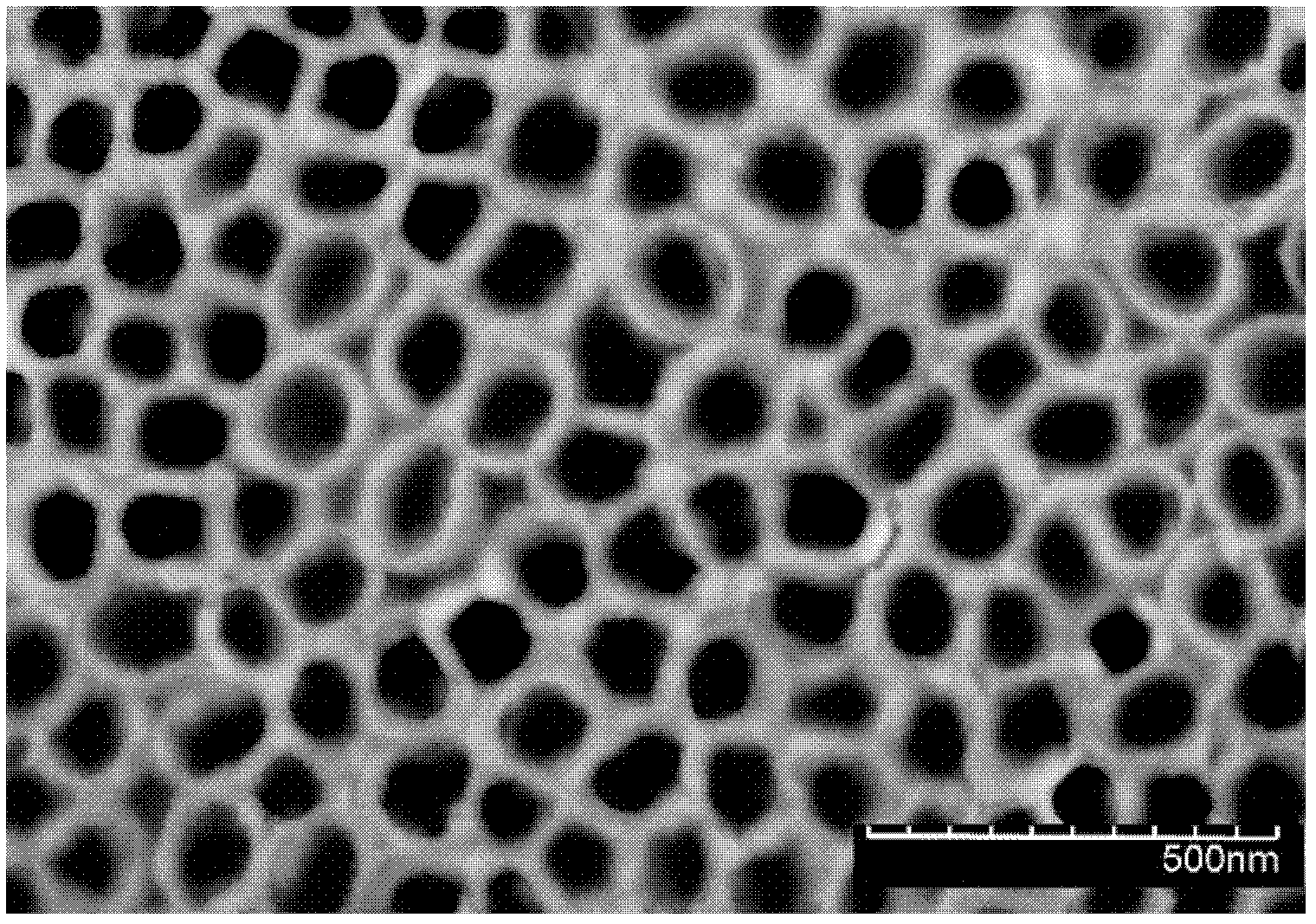

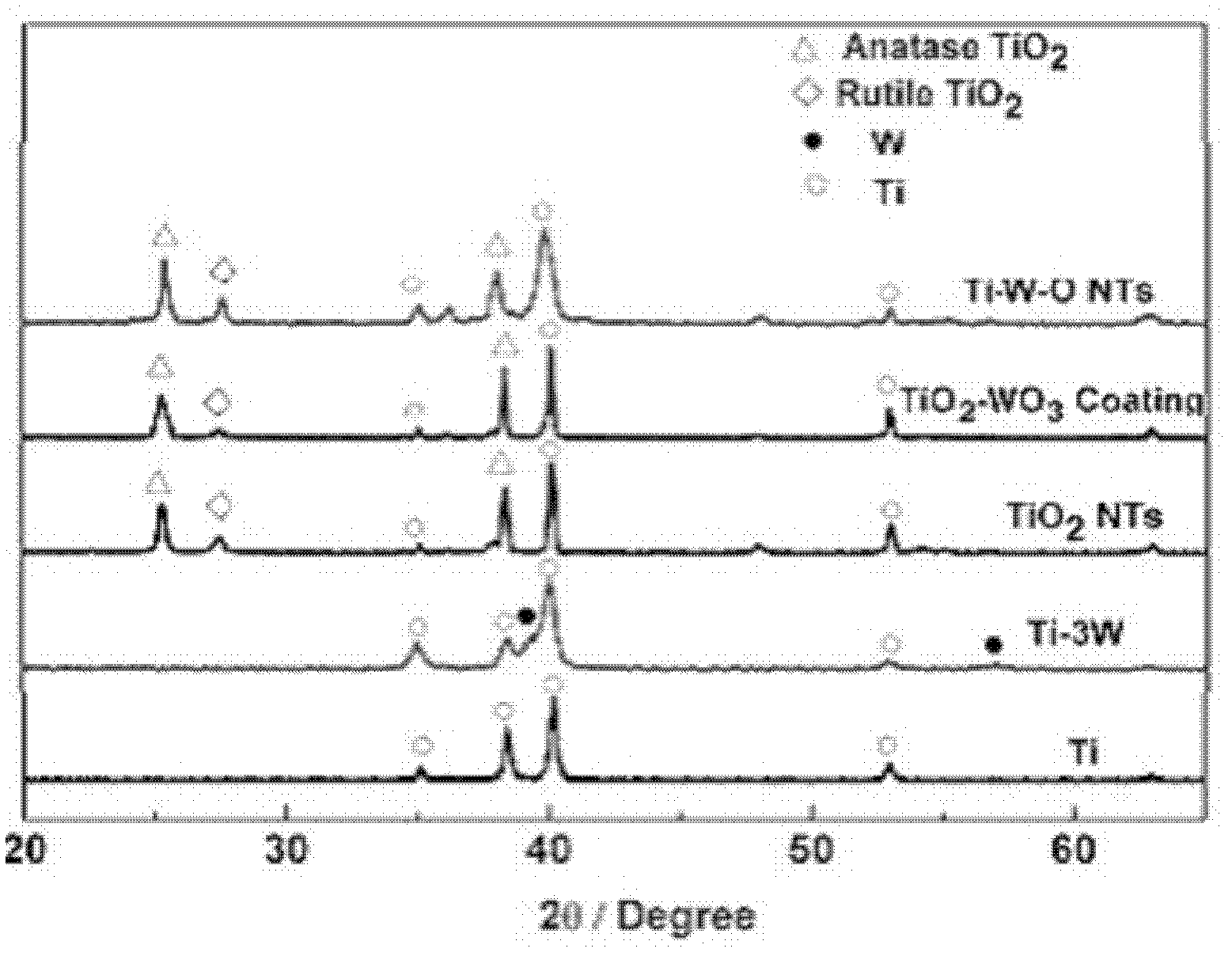

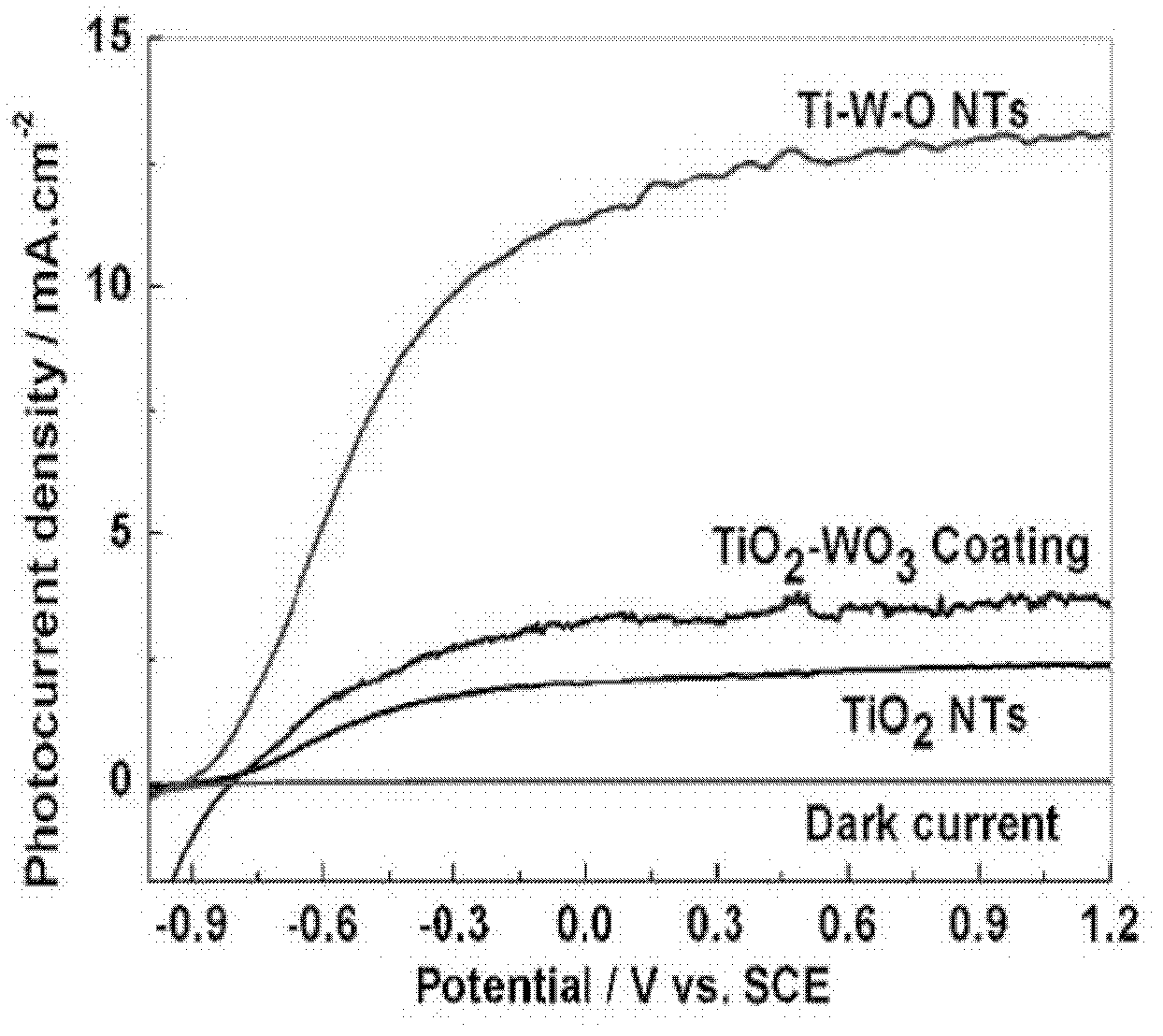

[0028] A Ti plate with a purity of 99.9% and a W wire with a purity of 99.9% are mixed in a certain proportion, and melted in a high-temperature arc melting furnace under the protection of an argon atmosphere to obtain a Ti-W alloy. It was cut into samples with a size of 15×50×1 mm using a wire cutting machine. The exact mass percentage of W in the alloy was determined to be 3% by inductively coupled plasma-atomic emission spectrometry (Optima 2100, Perkin-Elmer). After the alloy plate was polished with 100# and 500# sandpaper in turn, it was polished into a mirror surface with metallographic sandpaper, and then ultrasonically cleaned in acetone, distilled water, and absolute ethanol for 15 minutes each. At room temperature, the pretreated titanium-tungsten alloy sheet wa...

Embodiment 2

[0035] A preparation of a titanium-tungsten alloy oxide nanotube array for photoelectrically degrading organic pollutants with high efficiency, specifically comprising the following steps:

[0036] A Ti plate with a purity of 99.9% and a W wire with a purity of 99.9% are mixed in a certain ratio, and melted in a high-temperature arc melting furnace under the protection of an argon atmosphere to obtain a Ti-W alloy. It was cut into samples with a size of 15×50×1 mm using a wire cutting machine. The exact mass percentage of W in the alloy was determined to be 3% by inductively coupled plasma-atomic emission spectrometry (Optima 2100, Perkin-Elmer). After the alloy plate was polished with 100# and 500# sandpaper in turn, it was polished into a mirror surface with metallographic sandpaper, and then ultrasonically cleaned in acetone, distilled water, and absolute ethanol for 10 minutes respectively. At room temperature, the pretreated titanium-tungsten alloy sheet was used as the ...

Embodiment 3

[0038] A preparation of a titanium-tungsten alloy oxide nanotube array for photoelectrically degrading organic pollutants with high efficiency, specifically comprising the following steps:

[0039] A Ti plate with a purity of 99.9% and a W wire with a purity of 99.9% are mixed in a certain ratio, and melted in a high-temperature arc melting furnace under the protection of an argon atmosphere to obtain a Ti-W alloy. It was cut into samples with a size of 15×50×1 mm using a wire cutting machine. The exact mass percentage of W in the alloy was determined to be 5% by inductively coupled plasma-atomic emission spectrometry (Optima 2100, Perkin-Elmer). After the alloy plate was polished with 100# and 500# sandpaper in turn, it was polished into a mirror surface with metallographic sandpaper, and then ultrasonically cleaned in acetone, distilled water, and absolute ethanol for 20 minutes respectively. At room temperature, the pretreated titanium-tungsten alloy sheet was used as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com