Microwave dielectric ceramics and preparation process thereof

A microwave dielectric ceramic and carbonate technology, applied in the field of microwave dielectric ceramics, can solve the problems of volatile material density, high ceramic sintering temperature, damage to the performance of ceramic materials, etc. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

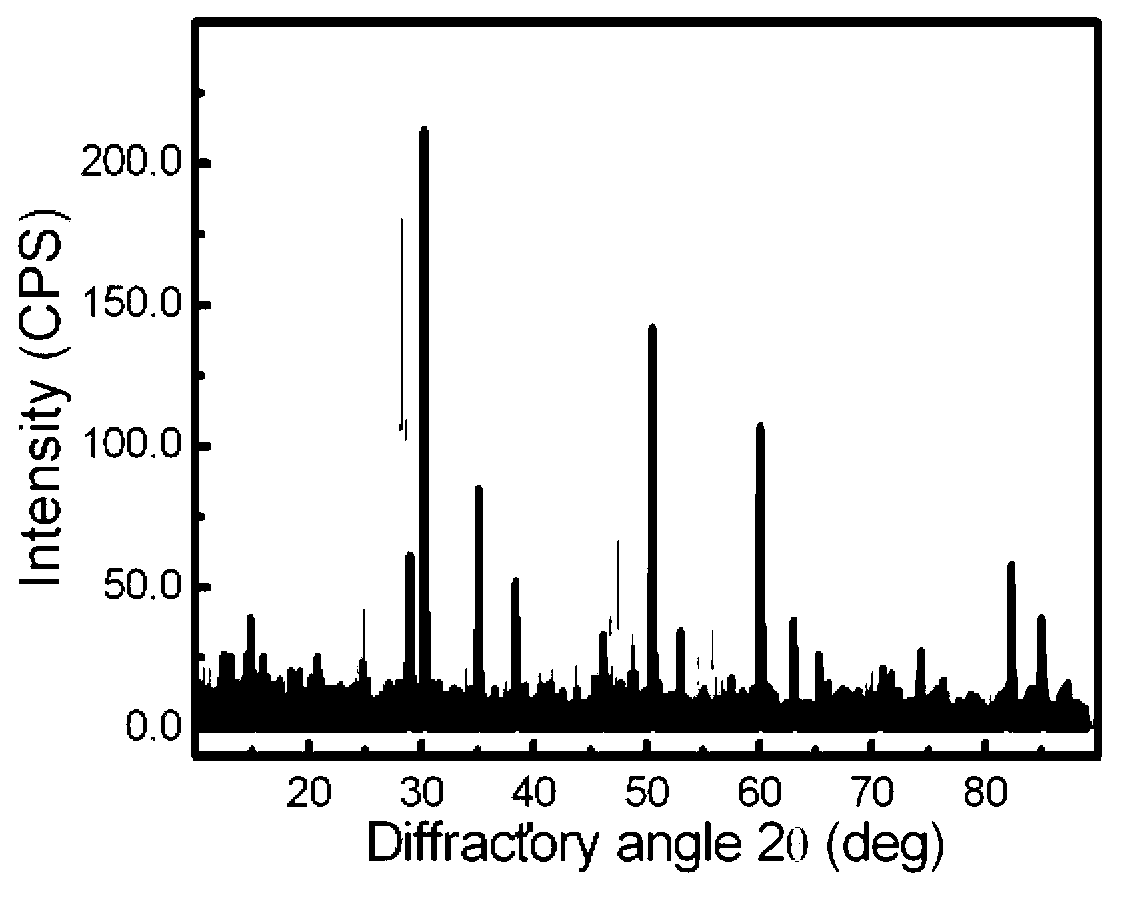

Embodiment 1

[0046] Weigh the raw materials according to the molecular formula of the formula: the molecular formula is Na 0.5 Gd 4.5 Ti 4 o 15 , the molecular weight is 1150.7109, the mass of ingredients is 12.78g, and the molar number of ingredients is 0.011;

[0047] The preparation method is:

[0048] (1) Weigh the required raw material Na 2 CO 3 Mass is 0.2950 g; Gd 2 o 3 The mass is 8.7184 g, (C 4 h 9 O) 4 The mass of Ti is 15.4358 g.

[0049] Prepare 0.011 moles of Na 0.5 Gd 4.5 Ti 4 o 15 , take 0.22 moles of EDTA acid, take 0.275 liters of 25% to 28% ammonia water, add EDTA acid to the ammonia solution, and add the designed amount of butyl titanate, at 60 o C~100 o Under C, adjust the pH value to 3-5 with nitric acid, keep warm and stir to dissolve;

[0050] Add nitric acid into gadolinium oxide, stir until gadolinium oxide is completely dissolved, generate gadolinium nitrate and add it to the above mixed solution, and add the designed amount of sodium carbonate to...

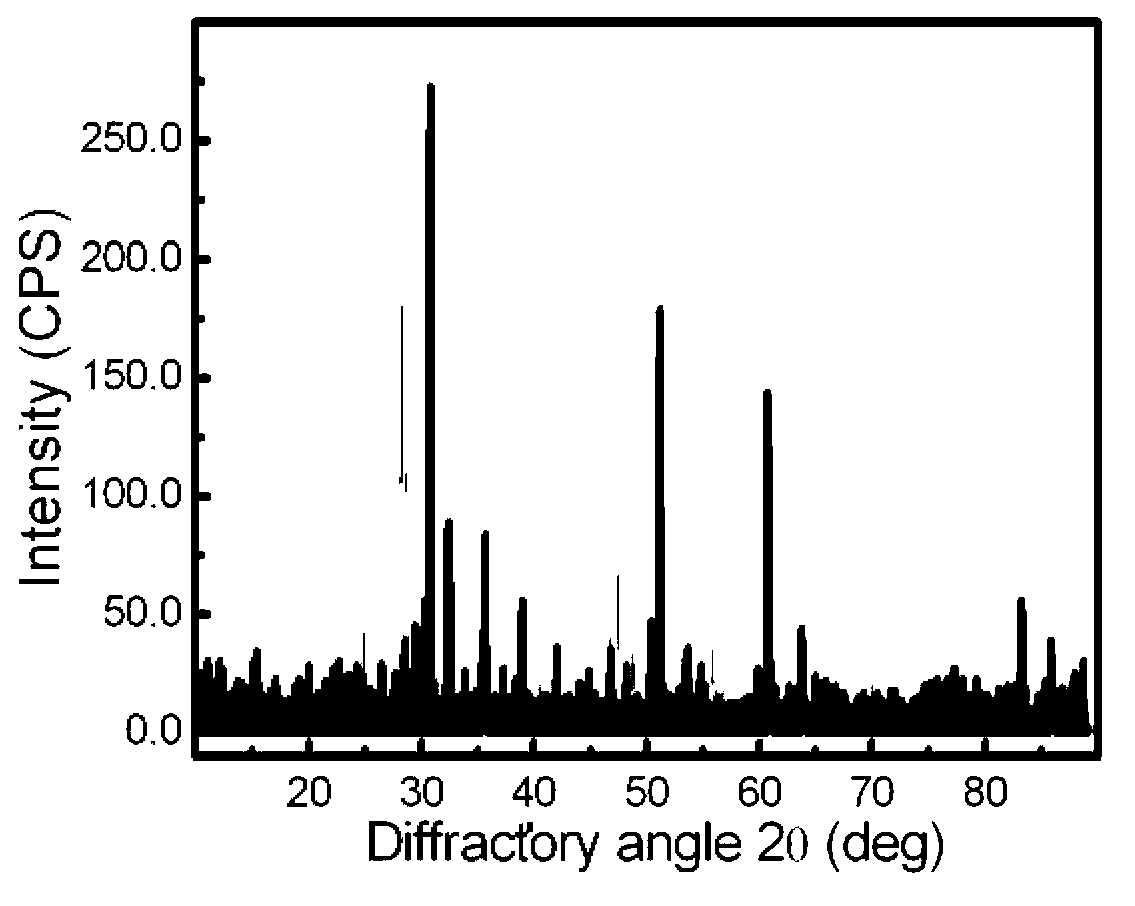

Embodiment 2

[0057] Weigh the raw materials according to the molecular formula of the formula: the molecular formula is Na 0.5 Dy 4.5 Ti 4 o 15 , the molecular weight is 1174.3359, the mass of ingredients is 13.05 g, and the molar number of ingredients is 0.011;

[0058] The preparation method is:

[0059] (1) Weigh the required raw material Na 2 CO 3 Mass is 0.2950 g; Dy 2 o 3 The mass is 9.3574 g, (C 4 h 9 O) 4 The mass of Ti is 15.4358 g.

[0060] Prepare 0.011 moles of Na 0.5 Dy 44.5 Ti 4 o 15 , with 0.132 moles of EDTA acid, take 0.22 liters of 28% ammonia water, add EDTA acid to the ammonia solution, and add a designed amount of butyl titanate, at 60 o Under C, adjust the pH value to 3-5 with nitric acid, keep warm and stir to dissolve;

[0061] Add nitric acid to dysprosium oxide, stir until dysprosium oxide is completely dissolved, add to the above mixed solution, and add the designed amount of sodium carbonate to the above solution.

[0062] The above mixed soluti...

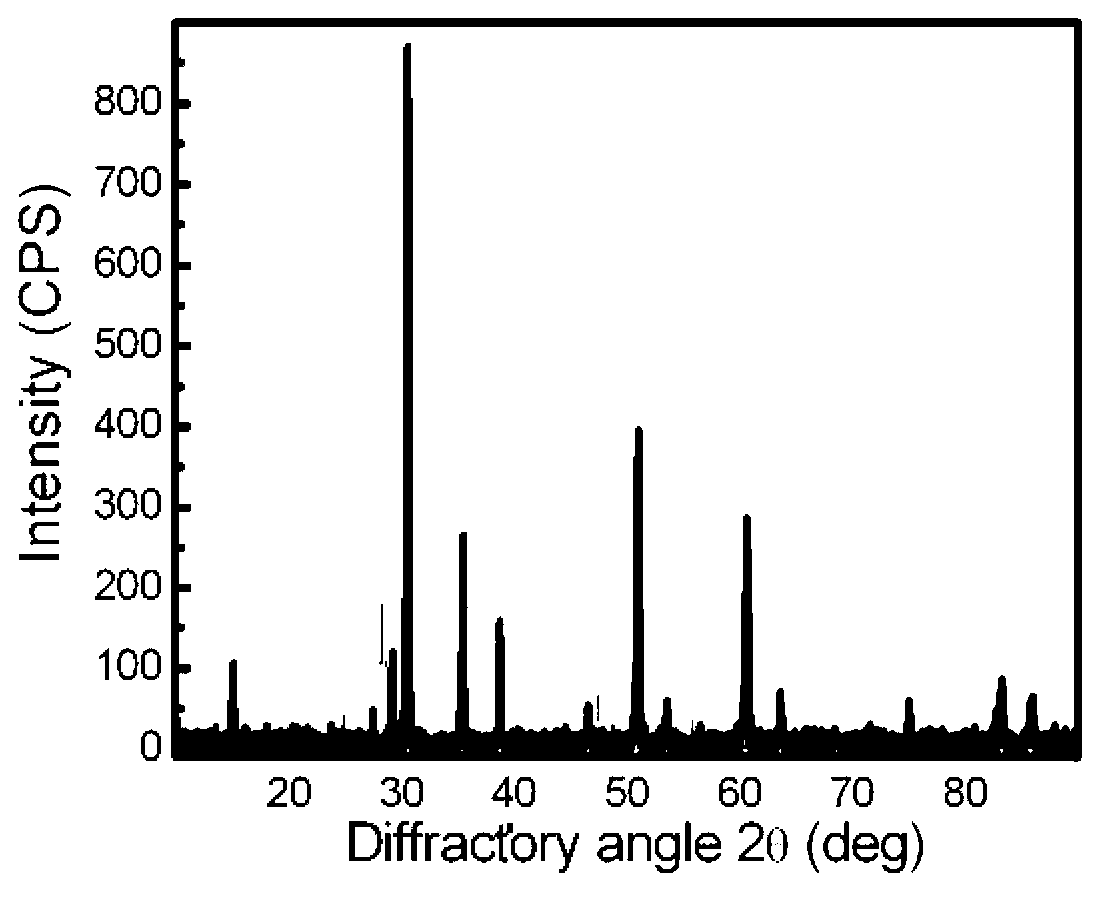

Embodiment 3

[0068] Weigh the raw materials according to the molecular formula of the formula: the molecular formula is Na 0.5 Er 4.5 Ti 4 o 15 , the molecular weight is 1195.7559, the mass of ingredients is 13.29 g, and the molar number of ingredients is 0.011;

[0069] The preparation method is:

[0070] (1) Weigh the required raw material Na 2 CO 3 Mass is 0.2950 g; Er 2 o 3 The mass is 9.5640 g, (C 4 h 9 O) 4 The mass of Ti is 15.4358 g.

[0071] Prepare 0.011 moles of Na 0.5 Er 4.5 Ti 4 o 15, with 0.275 moles of EDTA acid, take 0.33 liters of 25% ammonia water, add EDTA acid to the ammonia solution, and add a designed amount of butyl titanate, at 100 o Under C, adjust the pH value to 3-5 with nitric acid, keep warm and stir to dissolve;

[0072] Nitric acid is added to the erbium oxide, stirred until the erbium oxide is completely dissolved and added to the above mixed solution, and the designed amount of sodium carbonate is also added to the above solution.

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com