Alloy inert anode for aluminium electrolysis and preparation method thereof

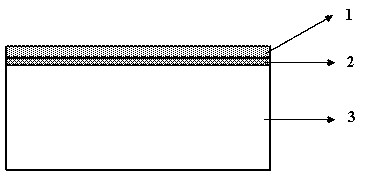

An inert anode and aluminum electrolysis technology, which is applied in the field of low-temperature aluminum electrolysis alloy inert anode and its preparation, can solve the problems of increasing anode cost, useless industrial application, thin precious metal coating, etc., to achieve corrosion reduction and long-term stable corrosion Protection, low porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of alloy inert anode for aluminum electrolysis of the present invention, the step of its preparation process comprises:

[0027] (1) Before spraying the alloy inert anode matrix alloy for aluminum electrolysis, clean it with organic matter (such as acetone) to remove oil stains; then use ceramic or metal sand (such as brown corundum sand or steel sand) to sandblast or shot the surface treatment to increase surface roughness;

[0028] (2) The iron-nickel-based alloy powder with a weight ratio of iron and nickel of 1:2 to 2:1 is used as the spraying powder, the content of iron and nickel is more than 90%, and the rest is Al, Cu, Co, Zn, Si, Mn, etc. One or several metal elements of the element, the content is 0-10%. Prepare iron-nickel-based alloy inner coating (thickness: 100μm-200μm) on the alloy surface by plasma spraying method, specific spraying process parameters: spraying voltage 40V-50V, spraying current 400A-500A, main gas flow: 40L / ...

Embodiment 1

[0031] (a) Before spraying the alloy substrate, wash it with acetone to remove oil stains; then use brown corundum sand to sandblast the surface to increase the surface roughness;

[0032] (b) Use iron-nickel alloy powder with a weight ratio of iron and nickel of 1:2 as the spraying powder, and use the plasma spraying method to prepare an iron-nickel alloy inner coating with a thickness of 100 μm on the surface of the alloy substrate. The specific spraying process parameters: spraying Voltage 40V, spraying current 400A, main air flow: 40L / min, auxiliary air flow: 5L / min, powder feeding volume 20g / min, spraying distance 80mm;

[0033] (c) Using nickel ferrite ceramic powder as the spraying powder, the nickel ferrite ceramic powder is sprayed onto the surface of the alloy substrate with an iron-nickel alloy coating by plasma spraying method to prepare a nickel ferrite ceramic outer coating with a thickness of 150 μm Layer, specific spraying process parameters: spraying voltage 4...

Embodiment 2

[0036] (a) Before spraying the alloy substrate, wash it with acetone to remove oil stains; then use brown corundum sand to sandblast the surface to increase the surface roughness;

[0037] (b) Use iron-nickel-aluminum alloy powder with a weight ratio of iron and nickel of 1:2 and 6% aluminum as the spraying powder, and use the plasma spraying method to prepare an inner coating of iron-nickel-aluminum alloy with a thickness of 150 μm on the surface of the alloy substrate Layer, specific spraying process parameters: spraying voltage 45V, spraying current 450A, main air flow: 50L / min, auxiliary air flow: 7.5L / min, powder feeding amount 25g / min, spraying distance 90mm;

[0038] (c) Using nickel aluminate ceramic powder as the spraying powder, the nickel aluminate ceramic powder is sprayed onto the surface of the alloy substrate with iron-nickel-aluminum alloy coating by plasma spraying method to prepare a nickel aluminate ceramic surface with a thickness of 100 μm. Coating, specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com