Rapid determination method for content of banned azo dye

A technology that prohibits azo and fast determination, is used in measurement devices, material separation, analysis materials, etc. It can solve the problems of long test process and shorten the analysis time of gas chromatography-mass spectrometer, achieve low column bleed, overcome the problem of instrument Long analysis process and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

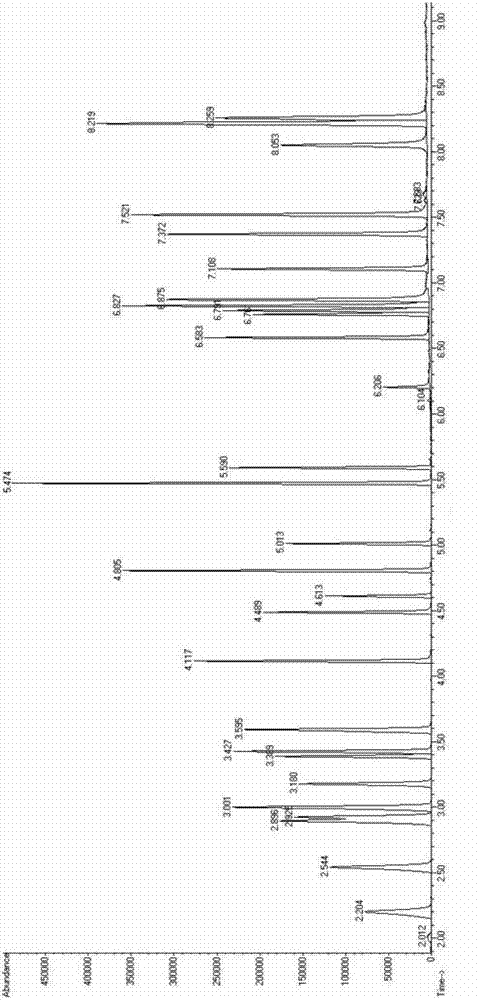

Image

Examples

Embodiment 1

[0018] 1) Preparation of sample spiked solution: Take 1 gram of blank cotton fabric without 24 kinds of aromatic amines in the reactor, add aromatic amines, and the prepared content is 30mg / kg;

[0019] 2) Reduction and extraction: Add 15ml of citrate buffer solution preheated to 70°C in the reactor, seal the reactor and keep it at 70±2°C for 30±1min, then add 3.0ml of 200mg / ml azo component Put the aqueous solution of sodium dithionite, the reducing cleavage agent, into the reactor, shake vigorously and directly keep it at 70±2°C for 30±1min, remove the reactor and cool it to room temperature within 2min;

[0020] Then, add 0.2ml of 10% m / m sodium hydroxide solution to the reaction solution and shake vigorously, transfer the reaction solution to a diatomaceous earth column, and let it fully absorb for 15min, and at the same time add 10ml of methyl tert-butyl ether to the reactor After 15 minutes, transfer the methyl tert-butyl ether and the fiber to the top of the column, col...

Embodiment 2

[0038] 1. Preparation of standard solution: Weigh 0.0100g of 24 kinds of standard aromatic amines, and set the volume to 100ml to obtain a mixed standard solution of 24 kinds of aromatic amines with a solubility of 100mg / L, and then use this solution to reconstitute the concentration of 1mg / L, 5mg / L, 30mg / L three standard solutions;

[0039] 2. Same as Example 1, analysis and qualitative and quantitative test results are shown in Table 2, and the analysis time is 9.15 minutes.

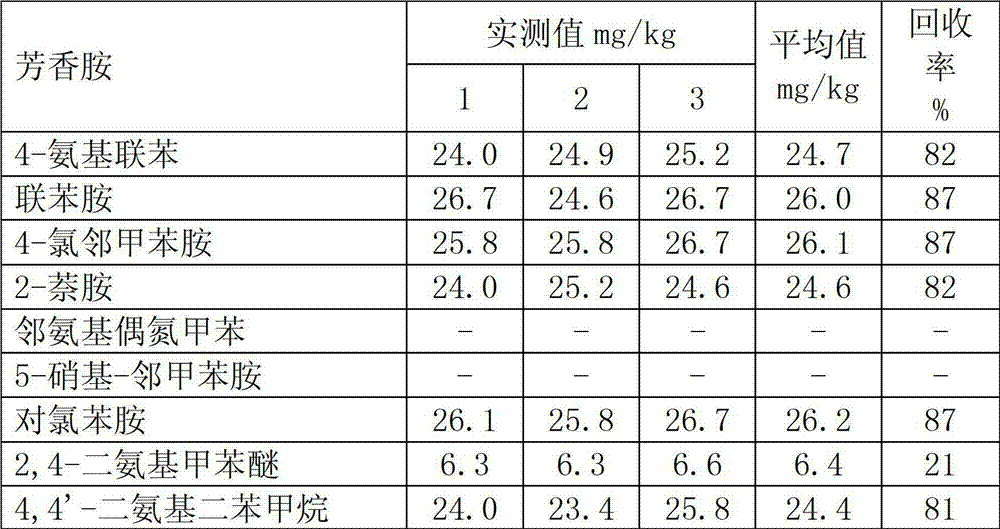

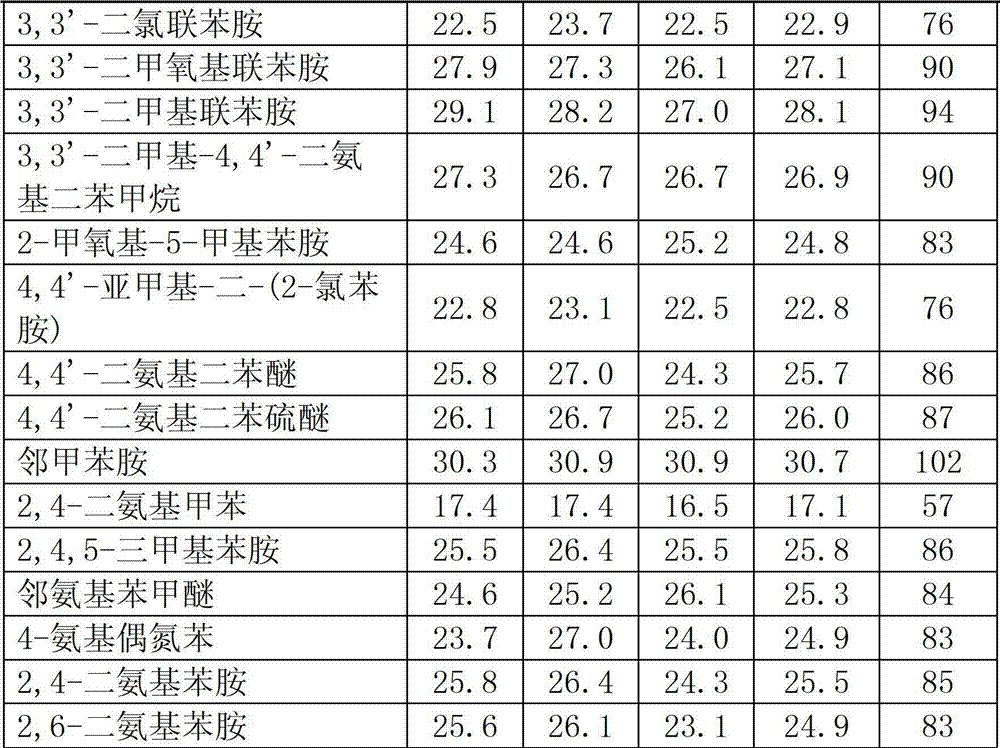

[0040] Table 2: Standard solution recovery rate

[0041]

[0042]

[0043] From above embodiment 1 and embodiment 2 as can be seen, adopt forbidden azo dye content measuring method of the present invention, its analysis time only needs 9.15 minutes, and adopt traditional testing method then need time spent 40-50 minutes, it can be seen The invention can greatly shorten the analysis time of the gas chromatography-mass spectrometer, and it can be judged from the test results that the recovery rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com