Method for preparing carbon/carbon composite yttrium silicate whisker reinforced C-AlPO4-SiCn complex external coating

A technology of c-alpo4-sicn and carbon composite materials, which is applied in the field of preparing carbon/carbon composite composite outer coatings, can solve the problems of easy cracking of the outer coating surface, inability to complete the preparation at one time, and insufficient coating thickness, etc., to achieve Good anti-oxidation performance, short preparation cycle, complete and sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

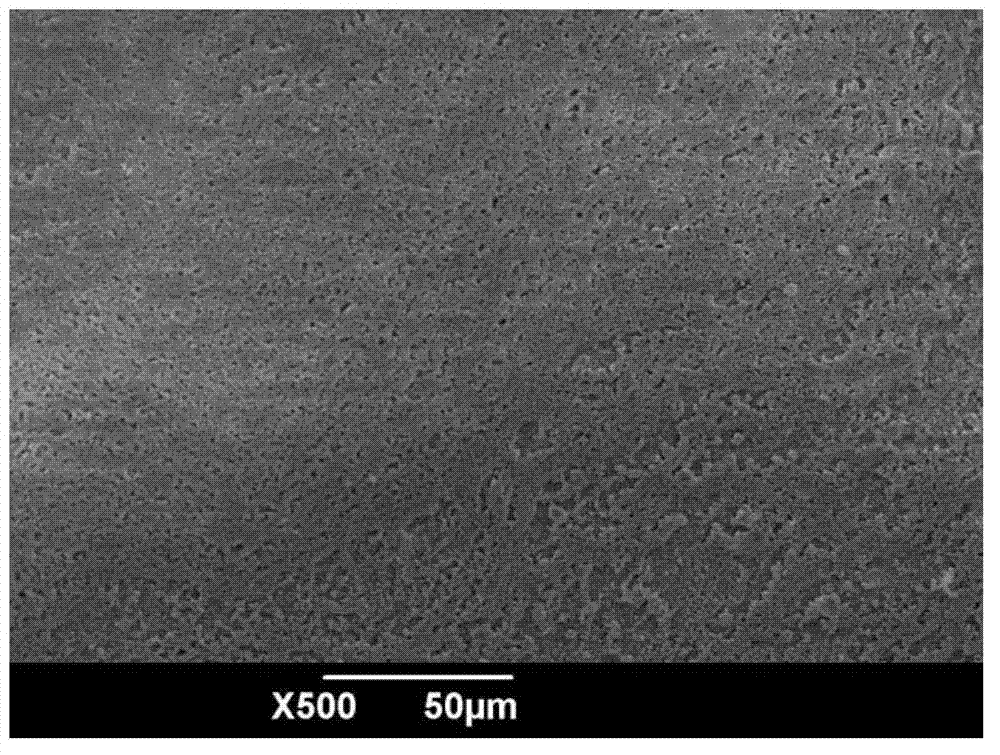

Image

Examples

Embodiment 1

[0020] 2) Take 1.0g of Y 2 Si 2 o 7 Whiskers, 2.0g of C-AlPO 4 Add 1.0g of nano-silicon carbide into the conical flask, then pour 300ml of isopropanol into the conical flask to obtain a suspension, then put the suspension into a 300W ultrasonic generator and vibrate for 80min, take it out and put it in Magnetic rotor, placed on a magnetic stirrer and stirred for 12 hours to obtain suspension A;

[0021] 3) Add 0.1g tellurium simple substance to the suspension A, put it into a 300W ultrasonic generator and shake it for 80min, take it out and stir it on a magnetic stirrer for 12h to get solution B;

[0022] 4) Pour solution B into the hydrothermal reaction kettle, and the filling degree is controlled at 68%; then the carbon / carbon composite material sample with SiC inner coating is clamped on the cathode clamp in the hydrothermal kettle, with graphite as the Anode, put the hydrothermal kettle into the coil of the electromagnetic induction heater; then connect the positive an...

Embodiment 2

[0025] 2) Take 8.0g of Y 2 Si 2 o 7 Whiskers, 5.0 g of C-AlPO 4 and 5.0g of nano-silicon carbide into the conical flask, then pour 500ml of isopropanol into the conical flask to obtain a suspension, then put the suspension into a 500W ultrasonic generator and vibrate for 60min, take it out and put it in Magnetic rotor, placed on a magnetic stirrer and stirred for 24 hours to obtain suspension A;

[0026] 3) Add 1.0g tellurium elemental substance to the suspension A, put it into a 500W ultrasonic generator and shake it for 60min, take it out and stir it on a magnetic stirrer for 24h to get solution B;

[0027] 4) Pour solution B into the hydrothermal reaction kettle, and the filling degree is controlled at 65%; then the carbon / carbon composite material sample with SiC inner coating is clamped on the cathode clamp in the hydrothermal kettle, with graphite as the Anode, put the hydrothermal kettle into the coil of the electromagnetic induction heater; then connect the positiv...

Embodiment 3

[0030] 2) Take 5.0g of Y 2 Si 2 o 7 Whiskers, 3.0 g of C-AlPO 4 and 3.0g of nano-silicon carbide were added to the conical flask, and then 400ml of isopropanol was poured into the conical flask to obtain a suspension, and then the suspension was placed in an 800W ultrasonic generator to vibrate for 50min, and then put into Magnetic rotor, placed on a magnetic stirrer and stirred for 36h to obtain suspension A;

[0031] 3) Add 0.5g tellurium elemental substance to the suspension A, put it into an 800W ultrasonic generator and shake for 50min, take it out and stir it on a magnetic stirrer for 36h to get solution B;

[0032] 4) Pour solution B into the hydrothermal reaction kettle, and the filling degree is controlled at 67%; then the carbon / carbon composite material sample with SiC inner coating is clamped on the cathode clamp in the hydrothermal kettle, with graphite as the Anode, put the hydrothermal kettle into the coil of the electromagnetic induction heater; then connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com