Synthetic method for tazobactam

A synthetic method, the technology of tazobactam, applied in the field of drug synthesis, can solve the problems of long synthetic route, increased risk, difficult industrialization, etc., and achieve the effects of mild reaction conditions, improved safety, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

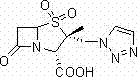

Image

Examples

Embodiment 1

[0017] 2ml of dimethylsulfoxide was contained in the reactor, and 0.57mmol of propiolic acid, 0.4mmol of 2β-azidomethylpenicillanic acid-1β-oxide, 0.14mmol of sodium ascorbate and 0.07mmol of Cuprous iodide, stirred and reacted at room temperature for 16 hours, extracted with ethyl acetate after the reaction, the organic layer was washed with saturated brine, dried over anhydrous sodium sulfate, filtered and distilled under reduced pressure to obtain the crude product, the crude product was used Ethyl acetate and petroleum ether at a volume ratio of 1:2 were used as the eluent for column chromatography to obtain tazobactam with a yield of 87%. The H NMR spectrum of tazobactam is: 1 H-NMR (400 MHz, CDCl 3 ): δ = 1.32(3H,s), 3.29(1H,dd), 3.70(1H,dd), 4.76(1H,s), 4.9(1H,dd), 5.16(1H,m), 5.25(1H, dd), 7.78(1H, s), 8.08(1H, s).

Embodiment 2

[0019] 2ml of dimethyl sulfoxide was contained in the reactor, and 0.55mmol of propiolic acid, 0.37mmol of 2β-azidomethylpenicillanic acid-1β-oxide, 0.14mmol of sodium ascorbate, 0.07mmol of Cuprous iodide and 0.19 mmol triethylamine were stirred and reacted at a temperature of 60°C for 3 hours, extracted with ethyl acetate after the reaction, the organic layer was washed with saturated brine, dried over anhydrous sodium sulfate, filtered and The crude product was obtained by distillation under reduced pressure, and the crude product was subjected to column chromatography with ethyl acetate and petroleum ether at a volume ratio of 1:5-1:3 as the eluent to obtain tazobactam with a yield of 80%.

Embodiment 3

[0021] 2ml of dimethyl sulfoxide was contained in the reactor, and 0.50mmol of propiolic acid, 0.34mmol of 2β-azidomethylpenicillanic acid-1β-oxide, 0.04mmol of sodium ascorbate, 0.02mmol of Cuprous iodide and 0.17mmol 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU), stirred and reacted for 5 hours at a temperature of 80°C, and reacted with acetic acid after the reaction ethyl acetate for extraction, the organic layer was washed with saturated brine, dried over anhydrous sodium sulfate, filtered and distilled under reduced pressure to obtain the crude product, and the crude product was washed with ethyl acetate and petroleum ether at a volume ratio of 1:5-1:2. The liquid was removed and column chromatography was carried out to obtain tazobactam with a yield of 84%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com