Rhizomucor miehei strain and application thereof in preparation of Beta-glucanase and chymosin

A technology of Rhizomucor miehei and dextranase, which is applied in the direction of biochemical equipment and methods, hydrolytic enzymes, fungi, etc., can solve the problems of long production cycle, low rennet level, high fermentation cost, etc., and achieve the production cycle Short, high enzyme production, low fermentation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, isolation and identification of bacterial strain

[0053] 1. Isolation of strains

[0054] The Rhizomucor miehei CAU432 provided by the invention is screened from soil.

[0055] The preparation method of the separation medium: oat (0.18-0.3mm particle size powder) 20g, soybean peptone 10g, KH 2 PO 4 5g, MgSO 4 ·7H 2 O 0.3g, CaCl 2 0.3g, 20g agar, add water to 1L, natural pH.

[0056] The preparation method of the primary screening medium: oat (0.18-0.3mm particle size powder) 20g, soybean peptone 10g, KH 2 PO 4 5g, MgSO 4 ·7H 2 O 0.3g, CaCl 2 0.3g, Congo red 0.05g, agar 20g, add water to 1L, natural pH.

[0057] Preparation method of fermentation medium: oat (0.18-0.3mm particle size powder) 20g, soybean peptone 10g, KH 2 PO 4 5g, MgSO 4 ·7H 2 O 0.3g, CaCl 2 0.3g, add water to 1L, natural pH.

[0058] The fresh soil samples were diluted, spread on the separation medium, and cultivated in a constant temperature incubator at 50°C. Whe...

Embodiment 2

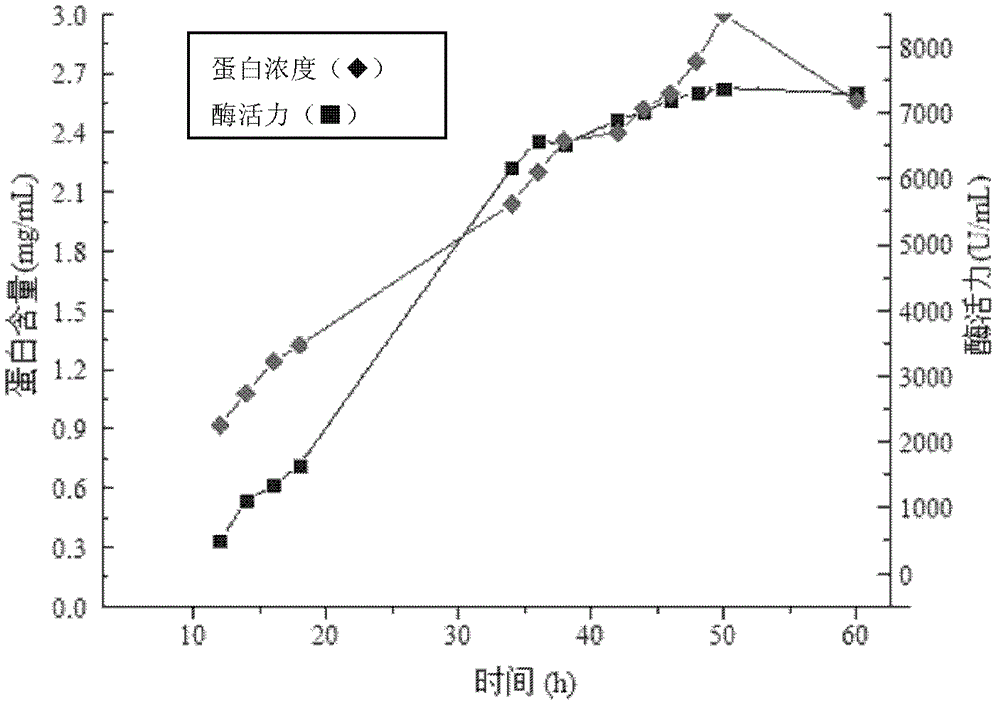

[0064] Example 2, Optimization of Conditions for the Preparation of β-Glucanase by Shake Flask Fermentation

[0065] 1. Screening of carbon source in fermentation medium

[0066]The preparation method of the fermentation medium in this step: carbon source 10g (0.45-0.9mm particle size range powder), peptone 10g, KH 2 PO 4 5g, MgSO 4 ·7H 2 O 0.3g, CaCl 2 0.3g, add water to 1L, natural pH. The following 15 carbon sources were used respectively: sugarcane husk, corn husk, corn stalk, oats, wheat bran, bagasse, corn cob, beer grains, rice husk, soluble starch, chitin, sorghum stalk, liquor distillers grains, bran and straw.

[0067] 1. Activation of strains

[0068] The preserved Rhizomucor miehei CAU432 was activated on the activation medium plate.

[0069] 2. Preparation of seed solution

[0070] The activated fresh strains were inoculated into the seed medium, and cultured on a reciprocating shaker in a constant temperature air bath at 50°C at 200 rpm for 24 hours to...

Embodiment 3

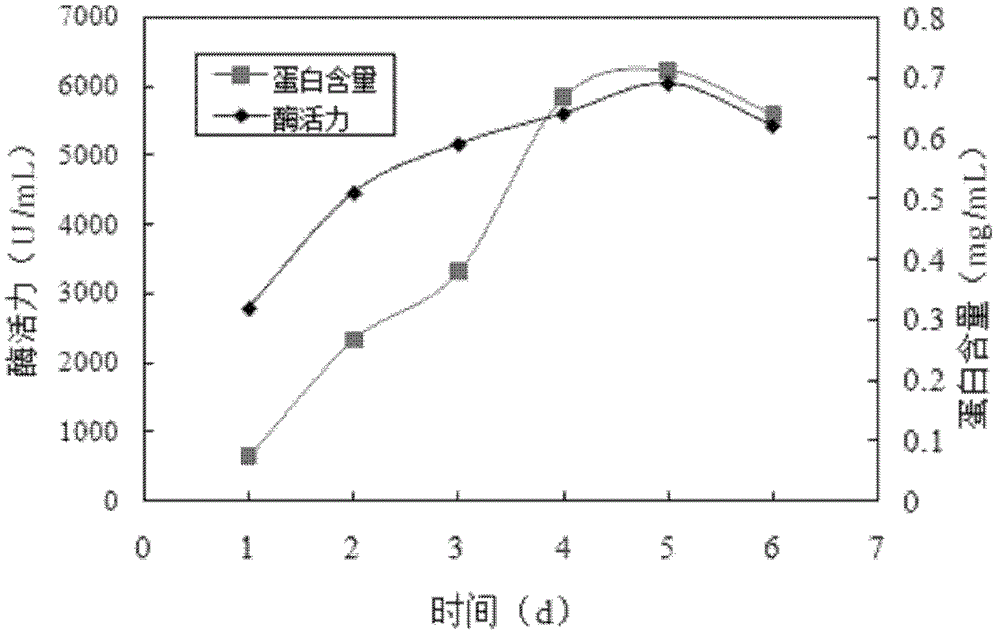

[0095] Example 3, Conditions for preparing β-glucanase by solid fermentation

[0096] 1. Screening of carbon source in solid fermentation medium

[0097] 1. Activation of strains

[0098] Same as step 1 of embodiment 2.

[0099] 2. Preparation of seed solution

[0100] Same as step 1 of embodiment 2.

[0101] 3. Solid fermentation to produce β-glucanase

[0102] Basic culture solution A: peptone 10g, KH 2 PO 4 5g, MgSO 4 ·7H 2 O 0.3g, CaCl 2 0.3g, add water to 1L, natural pH.

[0103] Take by weighing 5g carbon source (the powder of 0.18-0.3mm particle diameter range) in 250mL Erlenmeyer flask, pour into basal culture solution A, obtain solid fermentation medium (adjust the content of solid fermentation medium by the addition of basal culture solution A) The water content is 80%), stir evenly with a glass rod, and sterilize at 121°C for 20 minutes; inoculate 1mL of the seed liquid in step 2 after the solid fermentation medium is cooled, mix it and place it in a 50°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com