Preparation method of silicon and carbon-coated graphene composite cathode material

A graphene-coated, negative electrode material technology, applied in nanotechnology for materials and surface science, battery electrodes, electrical components, etc., can solve the problems of electrode cycle performance decline, limited commercial application, material structure damage, etc. To achieve the effect of convenient and practical preparation process, increase of irreversible capacity, and increase of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

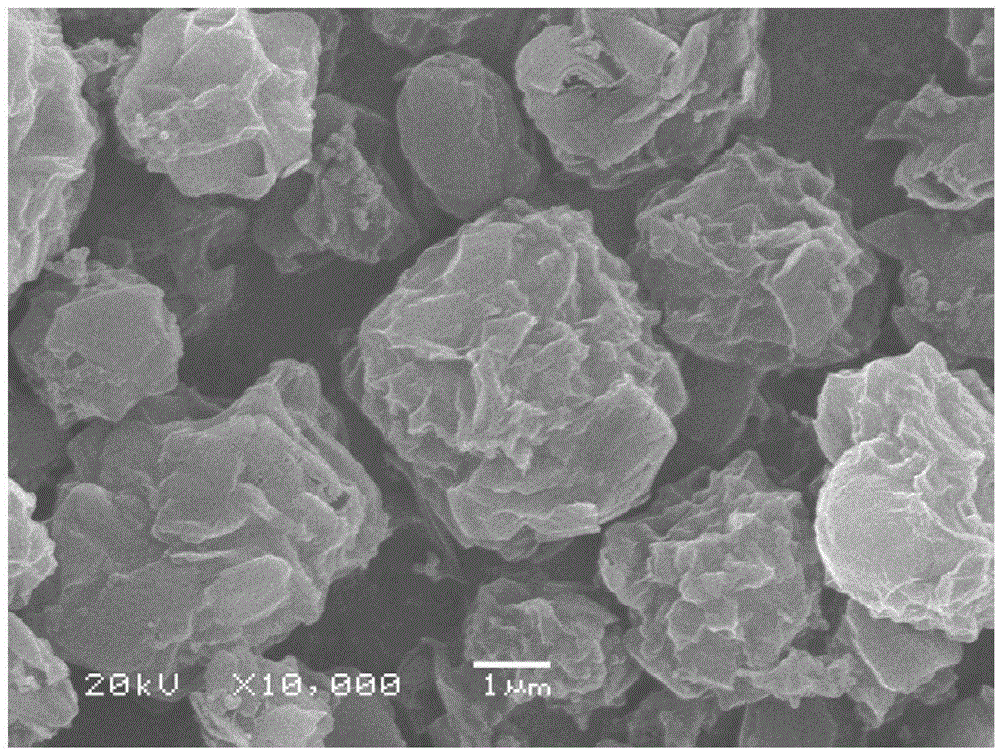

Image

Examples

Embodiment 1

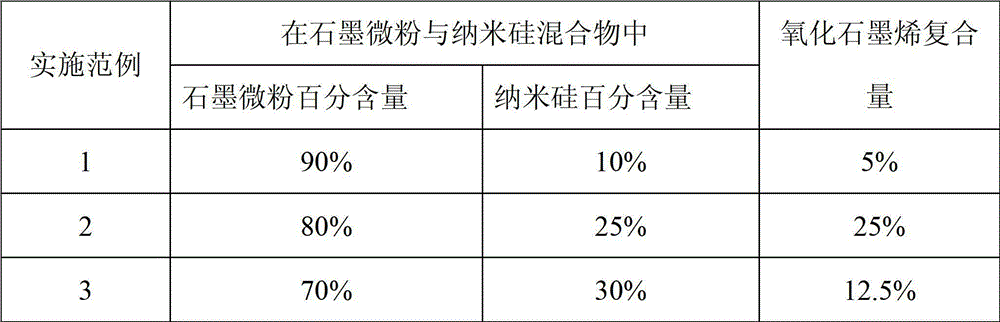

[0024] Prepare a certain concentration of graphene oxide dispersion by Hummer method, adjust the concentration of graphene oxide dispersion to 1mg / ml, add graphite powder (D50: 0.5μm) and nano-silicon (D50: 1nm) to the dispersion at the same time, graphite The mass ratio of micropowder and nano-silicon is 9: 1, adds dispersant polyethylene glycol 200 simultaneously (add-on is added by accounting for 1wt% of nano-silicon / graphite micropowder total mass), controls graphene oxide: nano-silicon and graphite micropowder The mass ratio is 1:20. Ultrasonic plus mechanical stirring is used to disperse for 1 hour to obtain a uniformly dispersed suspension. After the suspension is spray-dried at 170-200°C, the composite material precursor is obtained. The obtained powder was transferred to an argon atmosphere and treated at a constant temperature of 500°C for 2 hours, and then cooled with the furnace to obtain a thermally reduced graphene-coated silicon-carbon composite negative electrod...

Embodiment 2

[0027] Use the Hummer method to prepare a certain concentration of graphene oxide dispersion, adjust the concentration of graphene oxide dispersion to 10mg / ml, add graphite powder (D50: 5μm) and nano-silicon (D50: 500nm) to the dispersion at the same time, graphite powder The mass ratio with nano-silicon is 8:2, add dispersing agent polyvinyl alcohol simultaneously (add-on adds by accounting for 2wt% of nano-silicon / graphite micropowder gross mass), control graphene oxide: the mass ratio of nano-silicon and graphite micropowder is 5:20, ultrasound plus mechanical stirring for 1 hour to obtain a uniformly dispersed suspension, spray-dry the suspension at 170-200°C to obtain the composite material precursor. The obtained powder was transferred into an argon atmosphere and treated at a constant temperature of 600°C for 2 hours, and then cooled with the furnace to obtain a thermally reduced graphene-coated silicon-carbon composite negative electrode material.

[0028] The mixing r...

Embodiment 3

[0030] Use the Hummer method to prepare a certain concentration of graphene oxide dispersion, adjust the concentration of graphene oxide dispersion to 5mg / ml, add graphite powder (D50: 3μm) and nano-silicon (D50: 300nm) to the dispersion at the same time, graphite powder The mass ratio with nano-silicon is 7:3, while adding dispersant polyethylene oxide ((the addition is added by 2wt% accounting for the total mass of nano-silicon / graphite micropowder), control graphene oxide: the mass ratio of nano-silicon and graphite micropowder The ratio is 2.5:20, ultrasonic plus mechanical stirring for 2 hours to obtain a uniformly dispersed suspension, and after the suspension is spray-dried at 170-200°C, the composite material precursor is obtained. The obtained powder is transferred to an argon atmosphere and placed at a constant temperature of 800°C After processing for 2 hours, cooling with the furnace, the heat-reduced graphene-coated silicon-carbon composite negative electrode mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com