Method for extracting biological protein from aurantiochytrium sp residue

A technology of Schizochytrium and protein, applied in animal feed, animal feed, application, etc., can solve the problem that it is difficult to perfectly replace fish meal, achieve comprehensive utilization and increase economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Preparation of secondary seed liquid: Put the above-mentioned primary seed liquid into a 500ml shake flask containing 100ml seed culture medium, in a shaker at 20~30℃, rotate at 150~200rpm, cultivate for 24~48h to obtain secondary For the seed liquid, the above-mentioned seed medium and the first-level seed liquid use the same medium.

[0028] Connect the secondary seed liquid into a fermenter equipped with fermentation medium, the inoculum amount is 2-10%v / v, the aeration rate is 0.2-2vvm, the rotating speed is 200-800rpm, the tank temperature is 20-30℃, and the pH is 6-7. Schizochytrium oil, the above fermentation medium includes the following components: glucose 20-60g / L, yeast extract 5-30g / L, peptone 5-20g / L, potassium dihydrogen phosphate 0.5-8g / L, magnesium sulfate 0.5~5g / L, sodium citrate 0.5~5g / L, sea crystal 5~30g / L, vitamin B110~100mg / L, vitamin B610~100mg / L, vitamin B123~50mg / L, biotin 2~50mg / L. The above fermentation method can be batch fermentation, fed-bat...

Embodiment 1

[0031] Centrifuge the above fermentation broth, wash the insoluble matter twice, collect the insoluble matter algae, add an appropriate amount of water to adjust the viscosity, perform high-pressure homogenization and break the wall at a pressure of 40Mpa, and cycle twice;

[0032] Add n-hexane and ethanol to extract 3 times, and the organic phase is evaporated to dry the solvent to obtain crude oil. After alkali refining, decolorization and deodorization, 562 grams of polyunsaturated fatty acid refined oil is obtained, containing 38.5% of DHA;

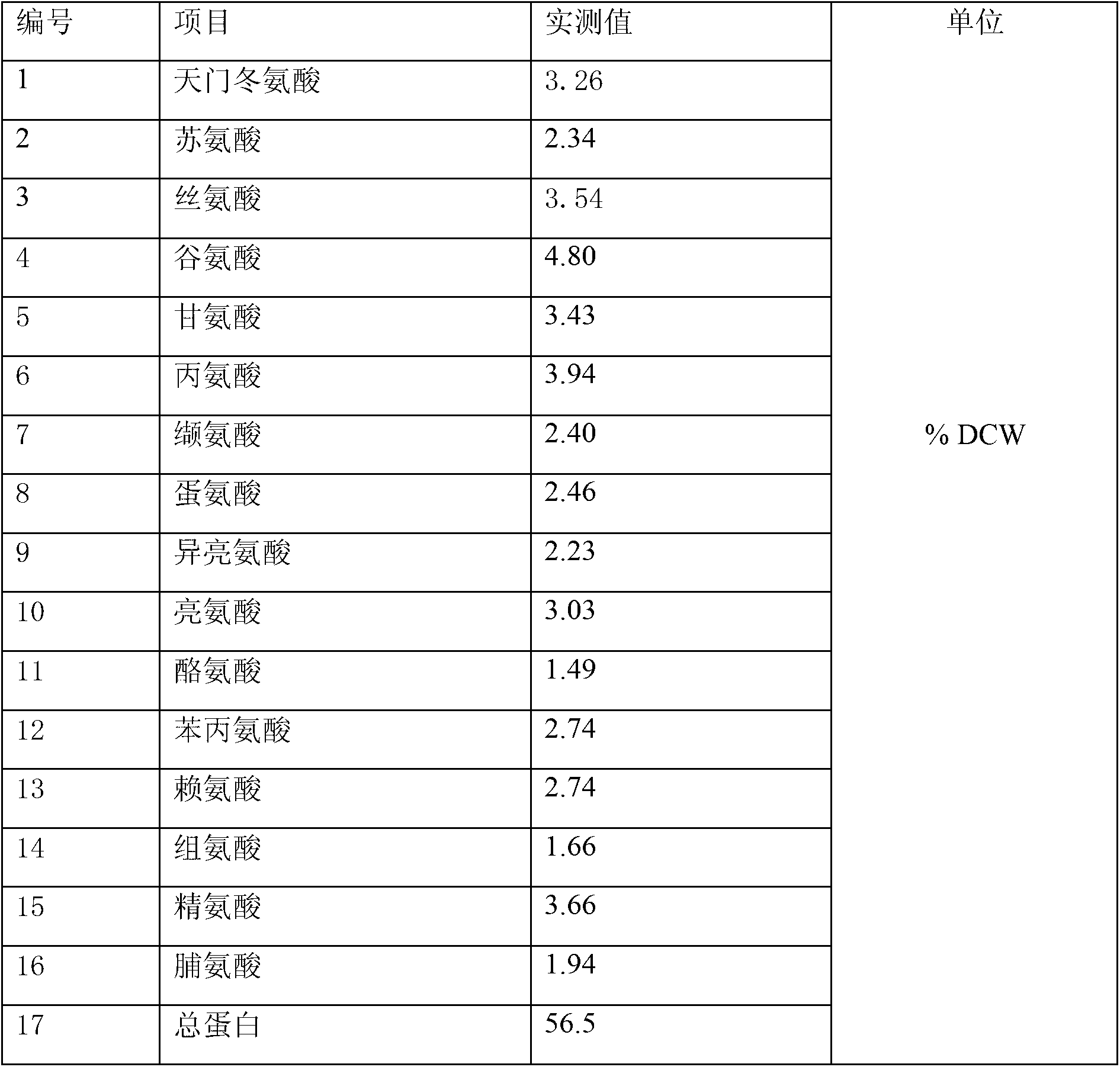

[0033] Add 1% pectinase to the remaining algae residue, hydrolyze at 50°C for 3 hours, then add 1% protease, temperature 50°C, action time 3 hours, spray drying, inlet air temperature 160°C, outlet air temperature 80°C, get dry powder about 350 G, protein content is about 56.5%, DHA content is 0.02%, it can be used as protein feed additive.

Embodiment 2

[0035] Centrifuge the fermentation broth, wash the insoluble matter twice, collect the insoluble matter algae, add appropriate amount of water to adjust the viscosity, and break the wall by enzymatic method;

[0036] Add n-hexane and ethanol to extract 3 times, evaporate the organic phase to dry the solvent to obtain crude oil. After alkali refining, decolorization and deodorization, 551 grams of polyunsaturated fatty acid refined oil is obtained, containing 38.3% DHA;

[0037] Add 0.1% pectinase to the remaining algae residue, hydrolyze at 60°C for 5 hours, then add 0.1% protease, hydrolyze at 60°C for 5 hours, spray dry, inlet air temperature 190°C, outlet air temperature 90°C, get dry powder about 354 grams, protein The content is about 56.9%, and the DHA content is 0.05%. It can be used as a protein feed additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com