Catalyst for generating hydrogen by hydroboron hydrolysis and preparation method of catalyst

A technology of borohydride and catalyst, which is applied in the field of borohydride hydrolysis hydrogen production catalyst and its preparation, can solve the problems of high catalytic activity and low price, and achieve the effect of simple preparation process, low cost and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

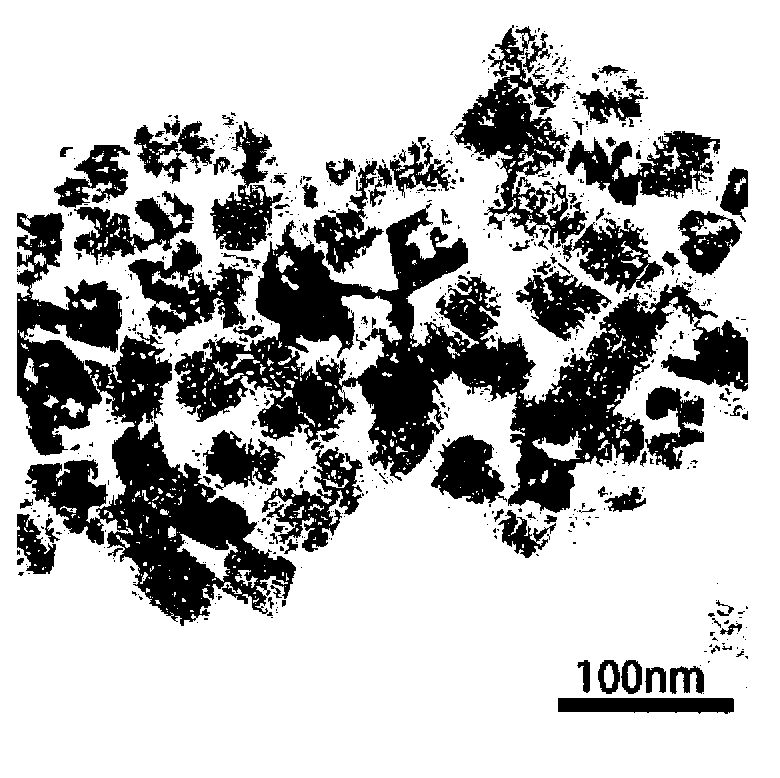

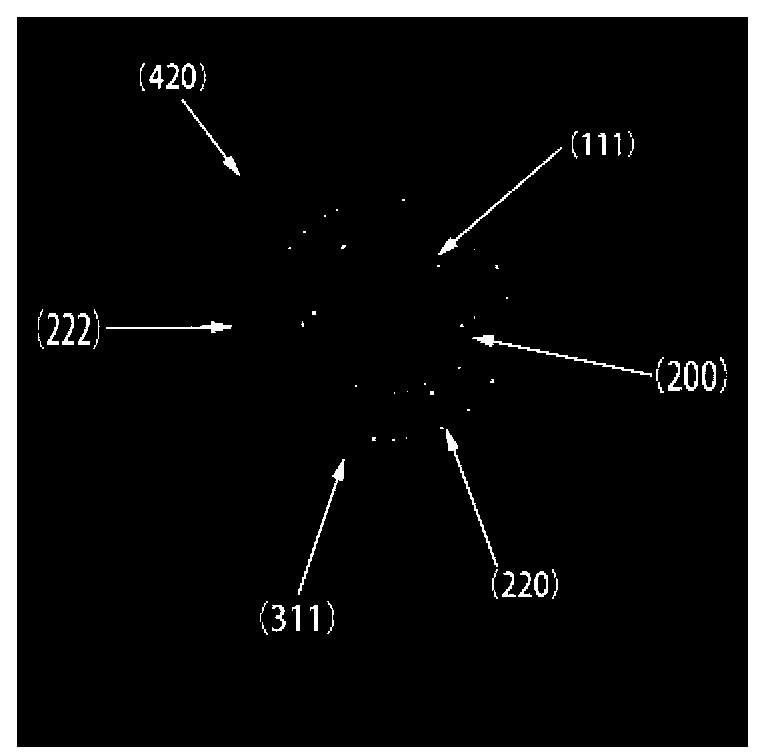

[0041] Add 0.5mmol cobalt acetate tetrahydrate and 10ml oleylamine into a four-necked flask, stir and mix under the protection of argon, then raise the temperature to 120°C, keep it warm for 30min to mix thoroughly, then inject 1.5mmol trioctylphosphine, and raise the temperature to After heat preservation at 240°C for 40 minutes, cool to room temperature, add ethanol to precipitate the product, take out the reaction mother liquor by centrifugation, then use acetone and n-hexane mixed solution to repeatedly wash three times, and finally vacuum dry to obtain a powder product. figure 1 It is a transmission electron microscope photograph of the product, and the size of the prepared nanocrystal is about 40nm, and has an octahedral shape. figure 2 It is the electron diffraction spectrogram of the product, confirming that the product is cobaltous oxide with a face-centered cubic structure.

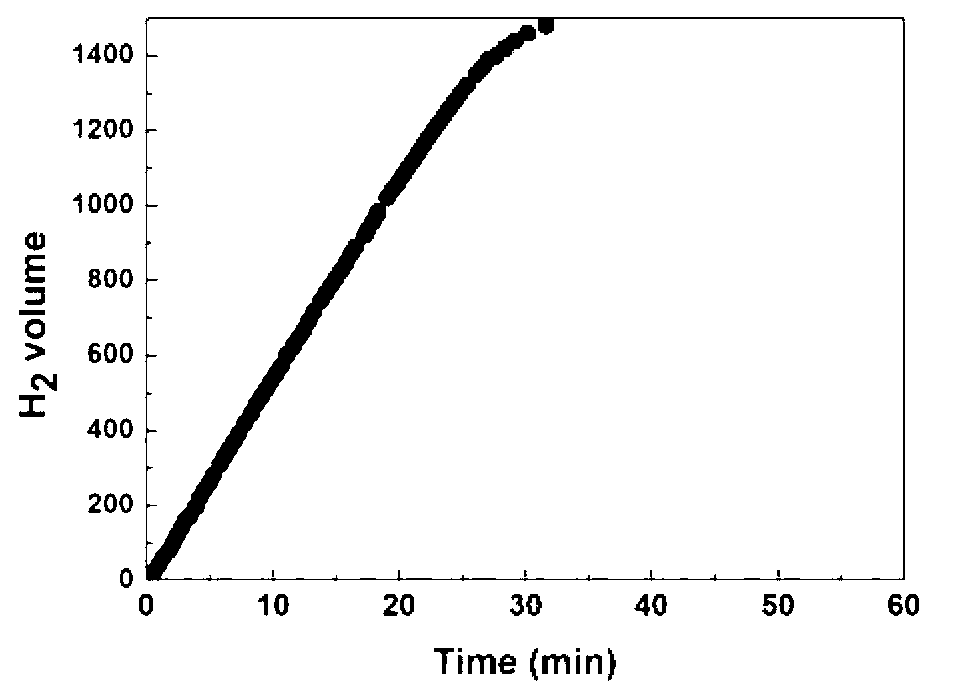

[0042] Using 10mg of the prepared cobaltous oxide nanocrystalline catalyst (the content of ...

Embodiment 2

[0044] Add 0.5mmol cobalt acetate tetrahydrate and 10ml bibenzyl ether into a four-necked bottle, stir and mix under the protection of argon, then raise the temperature to 130°C, keep it warm for 20min, remove excess water vapor, raise the temperature to 240°C, and keep it warm for 20min Cool to room temperature, add ethanol to precipitate the product, take out the reaction mother liquor by centrifugation, then use the mixed solution of acetone and n-hexane to wash repeatedly three times, and finally vacuum-dry to obtain the powder product. Figure 4 The transmission electron micrograph of the product shows that the prepared nanocrystals are in irregular shape. Figure 5 It is the electron diffraction spectrogram of the product, confirming that the product is cobaltous oxide with a face-centered cubic structure.

[0045] Using 10mg of the prepared cobaltous oxide nanocrystalline catalyst (the content of the active component cobaltous oxide is 100%), catalyze 5ml of alkaline so...

Embodiment 3

[0047] Add 0.5mmol cobalt acetate tetrahydrate and 10ml bibian ether into a four-necked bottle, stir and mix under the protection of argon, then raise the temperature to 130°C, keep it warm for 20min, remove excess water vapor, then add 2ml oleylamine, and mix well Then raise the temperature to 220°C, keep it warm for 60 minutes, and form a yellow-brown transparent complex, then raise the temperature to 240°C, keep it warm for 20 minutes, then cool to room temperature, add ethanol to precipitate the product, take out the reaction mother liquor by centrifugation, and then use acetone and n-hexane The mixed solution was repeatedly washed three times, and finally vacuum-dried to obtain a powder product. Figure 7 The transmission electron micrograph of the product shows that the size of the prepared nanocrystal is about 10nm, and the shape is approximately spherical. Figure 8 It is the electron diffraction spectrogram of the product, confirming that the product is cobaltous oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com