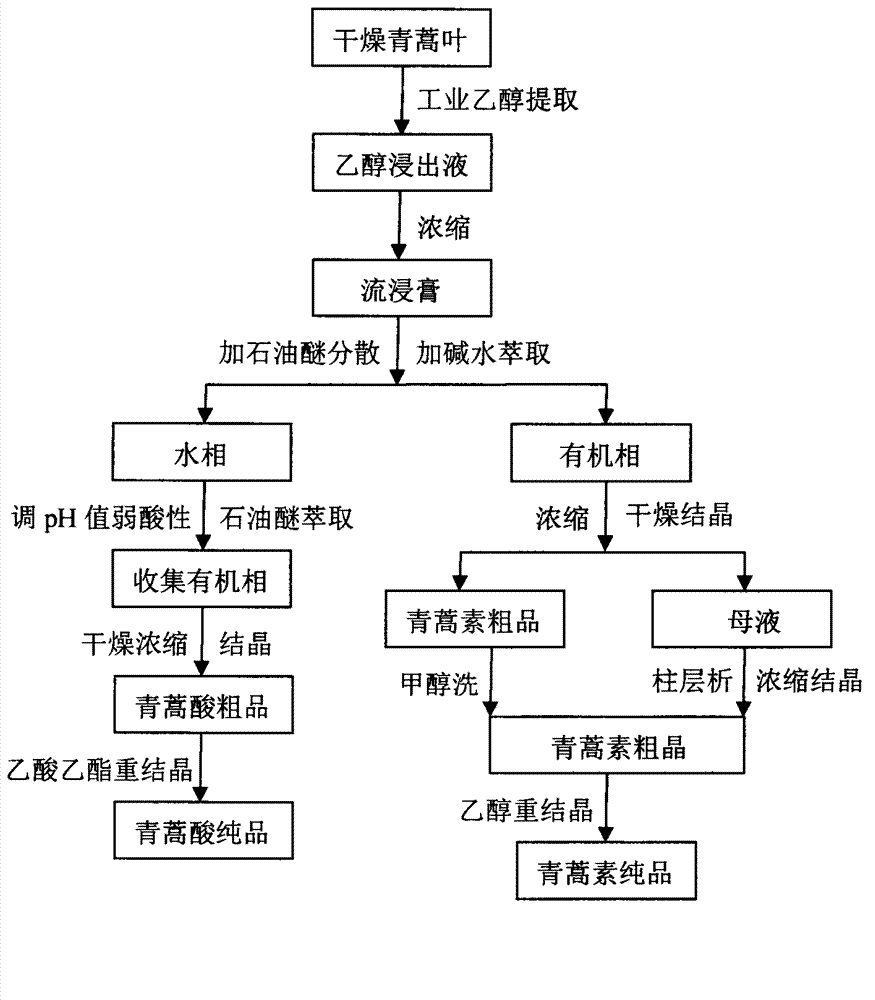

Simple and new technology for extracting and purifying arteannuin and artemisinic acid from southernwood through single process

A technology of artemisinin and artemisinic acid, applied in the direction of organic chemistry, can solve the problems of flammable and explosive solvents, low extraction recovery rate, complicated process flow, etc., achieve good content and purity, high extraction recovery rate, save The effect of the solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 500 kg of dried Artemisia annua leaves and put them in a 5-ton extraction tank, add 2.5 tons of industrial ethanol, stir at room temperature (about 25°C) and extract for 4 hours, twice for each batch, and use it for the third time. Filter and combine the extracts, concentrate under reduced pressure to 1 / 4 volume, add 1 ton of petroleum ether to disperse, transfer to the extraction tank, then adjust the pH value to 8 with sodium bicarbonate solution, and add water until the water phase is 1 / 4 of the volume of the organic phase. / 2, 1 ton of petroleum ether extracted twice. Combine the organic phases, concentrate to 1 / 20 volume, dry filter, cool and crystallize, filter to obtain crude artemisinin, wash the crude product with methanol to obtain coarse crystals of artemisinin; use 100% to 20% petroleum ether / ethyl acetate Or eluted with petroleum ether / acetone to obtain crude crystals of artemisinin column chromatography, combined the two kinds of crude crystals, and ...

Embodiment 2

[0024] The alkaline aqueous phase obtained above was adjusted to about 6-7 with acetic acid, then extracted twice with 500L of petroleum ether, the organic phase was combined and concentrated to 400L, dried and crystallized to obtain crude artemisinic acid, and then extracted with ethyl acetate Recrystallization obtained 13.5 kg of pure artemisinic acid. HPLC detection content is greater than 99.0%, related substances, simple impurities are less than 0.5%, and total impurities are less than 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com