Water-solution lithium ion battery negative pole material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as capacity drop and poor battery cycle performance, achieve great application potential, and easy control of microscopic shape and size , good charging and discharging stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

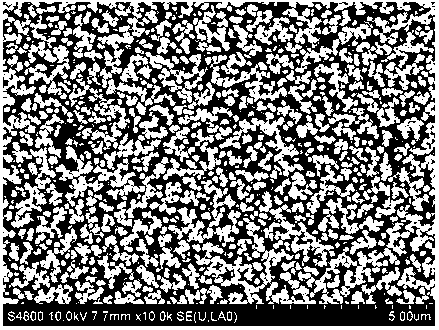

[0027] Tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) was dissolved in toluene to prepare a solution with a concentration of 10 wt%, and this solution was mixed with 0.1 mol / L TiCl 4 The toluene solution was mixed at a volume ratio of 3:1, mixed evenly and transferred to a hydrothermal reaction kettle, and 0.1 mol / L hydrochloric acid aqueous solution 8mL was added dropwise under stirring conditions to make it hydrolyze. Add the FTO glass substrate to the solution 5 minutes after the hydrolysis reaction occurs. Before putting the FTO substrate into the solution, it is ultrasonically cleaned with acetone for 10 minutes, then immersed in 1mol / L NaOH solution for 15 minutes, and finally washed three times alternately with ethanol and water, and baked. Dry. Transfer the hydrolysis reaction solution containing the matrix into a sealed hydrothermal reaction kettle, place it in a muffle furnace and raise the temperature to 200°C at a rate of 5°C / min for 4 hours to obtain a titanium dioxide...

Embodiment 2

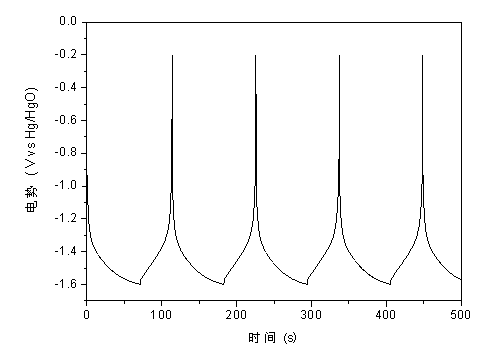

[0029] Under strong stirring conditions, add tetrabutyl titanate (0.5 mL) into ethylene glycol (20 mL) and mix well, then add 0.1 mol / L citric acid solution 12 mL dropwise under stirring conditions, and stir until transparent , to obtain the precursor solution. Then the precursor solution was poured into 80 mL of ethanol, stirred at room temperature for 10 min, and then allowed to stand for 2 h. The resulting solution was transferred to a reaction kettle, and a titanium sheet was placed as a substrate. The titanium sheet was ultrasonically cleaned with acetone for 20 minutes before being put in, then soaked in 1mol / L NaOH solution for 25 minutes, washed with ethanol and water alternately, and dried for later use. Adjust the temperature of the reactor to 250 °C and keep it warm for 0.5 h to obtain a thin film material with nanocone array titanium dioxide coated on the substrate. The charge-discharge curve diagram of the obtained titanium dioxide negative electrode material is ...

Embodiment 3

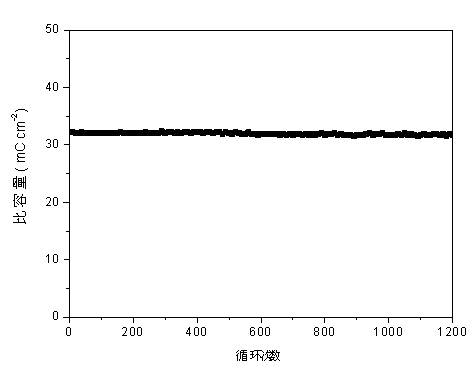

[0031] Tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) was dissolved in ethanol to prepare 50 mL of a solution with a concentration of 5 wt%. This solution was mixed with 0.1 M titanium tetrachloride ethanol solution at a volume ratio of 4:1 and then transferred to a hydrothermal reaction kettle. Then, 20 mL of 0.0.1 mol / L hydrochloric acid aqueous solution was added dropwise for hydrolysis. After the hydrolysis reaction occurred for 8 minutes, a stainless steel substrate was added to the solution, and the substrate treatment method was the same as in Example 2. After the hydrolysis reaction was completed, the hydrothermal reaction kettle was sealed and placed in a muffle furnace to raise the temperature to 180°C at 2°C / min for 2 h. After the reaction is finished and cooled, the substrate is taken out, washed, and dried to obtain a thin film material with titanium dioxide nanowire arrays. The cycle performance curve of the obtained nanowire array titanium dioxide anode material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com