Method for preparing high-quality graphene through catalytic oxidation multiple-intercalation

A catalytic oxidation, graphene technology, applied in graphene, chemical industry, sustainable manufacturing/processing, etc., to achieve high operating efficiency, improve production efficiency, and protect integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

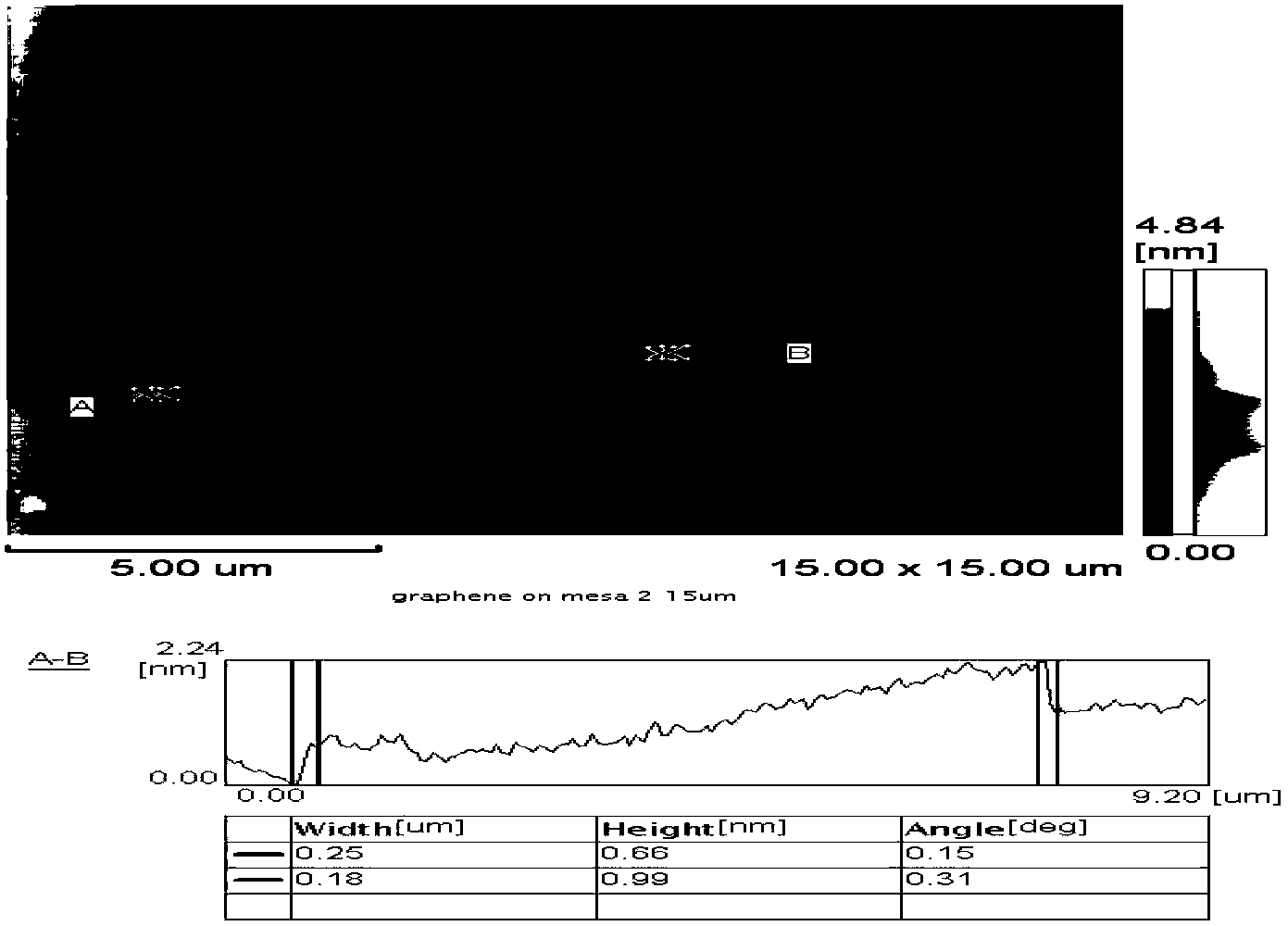

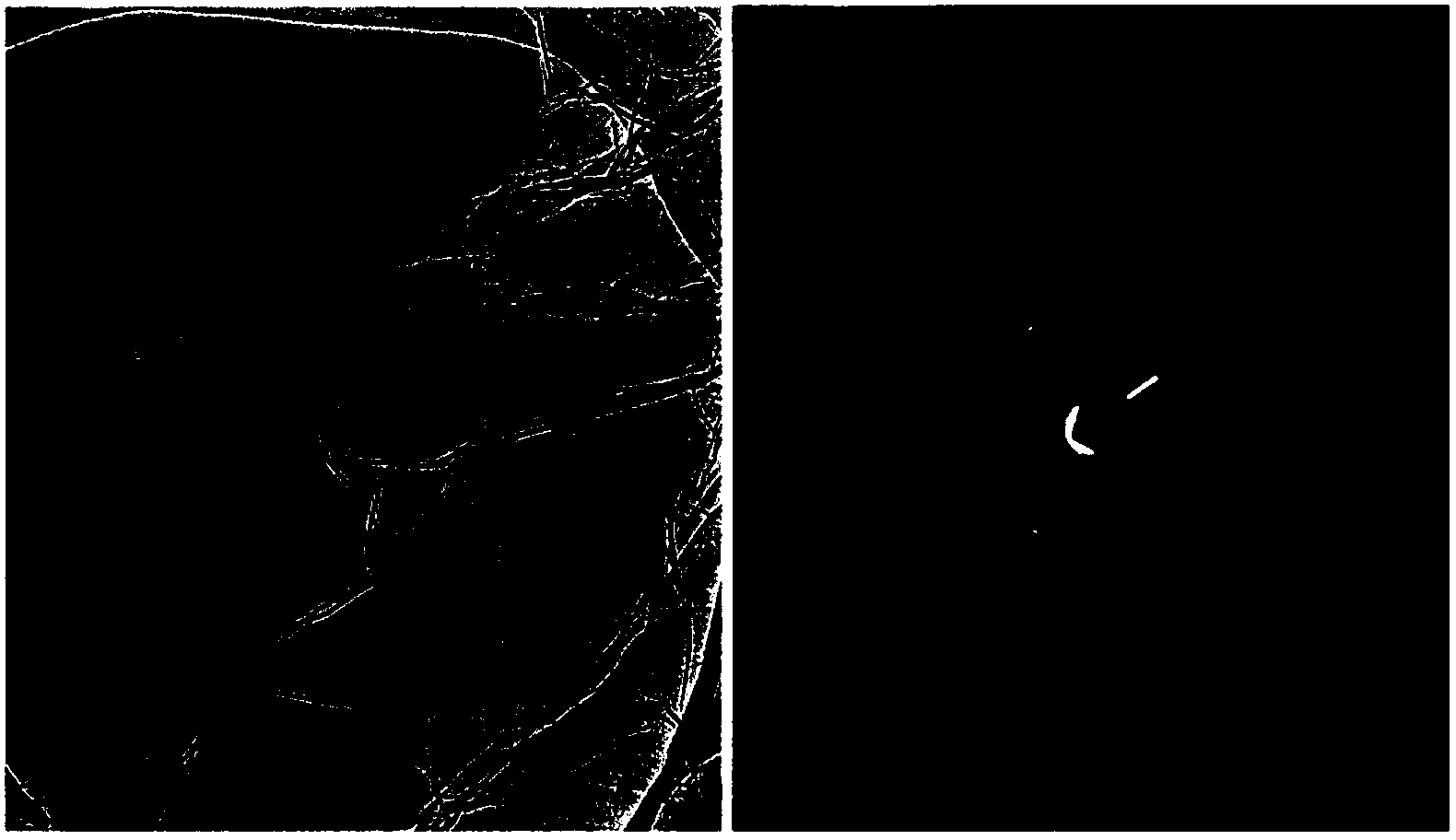

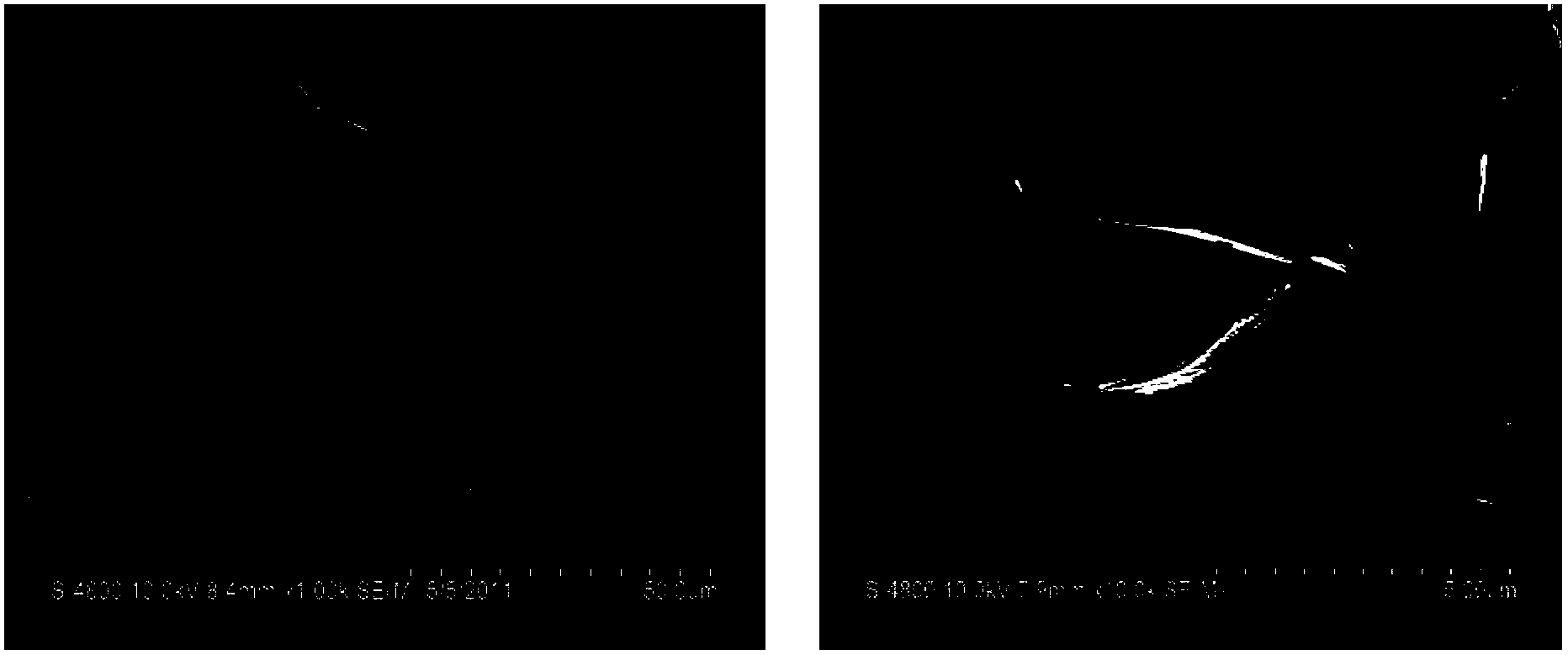

Image

Examples

Embodiment 1

[0032] (1) Pretreatment step: put 5g graphite in 25ml Fe 2+ with H 2 o 2 In the mixed aqueous solution, where Fe 2+ with H 2 o 2 The molar ratio is 1:40, the pH value of the solution is 3, the mechanical stirring rate is 500rpm and supplemented by ultraviolet light irradiation with a wavelength of 254nm for 3h, and then the graphite pretreatment product is filtered and washed;

[0033] (2) Intercalation and exfoliation step: place 4.5g of the graphite pretreated product obtained in step (2) in 20ml of cetyltrimethylammonium bromide aqueous solution for intercalation and exfoliation, the mechanical stirring rate is 300rpm, and the ultrasonic power is 1000W , the treatment time is 60min, and multi-layer graphene is obtained through filtration and washing;

[0034] (3) Repeat the pretreatment and intercalation stripping process of the multilayer graphene twice, and finally place the washed, filtered and dried product in a high-temperature reducing atmosphere (the volume rati...

Embodiment 2

[0037] (1) Pretreatment step: put 5g graphite in 25ml Fe 2+ with H 2 o 2 In the mixed aqueous solution, where Fe 2+ with H 2 o 2 The molar ratio is 1:30, the pH value of the solution is 4, the mechanical stirring rate is 400rpm and supplemented by ultraviolet light irradiation with a wavelength of 254nm for 2h, and then the graphite pretreatment product is filtered and washed;

[0038] (2) Intercalation and stripping step: put 4.3g of the graphite pretreated product obtained in step (2) into 20ml of tetrabutylammonium bromide aqueous solution for intercalation and stripping, the mechanical stirring rate is 400rpm, the ultrasonic power is 1200W, and the treatment time is 60min , obtain multilayer graphene through filtering and washing;

[0039] (3) Repeat the pretreatment and intercalation stripping process of the multilayer graphene three times, and finally place the washed, filtered and dried product in a high-temperature reducing atmosphere (the volume ratio of hydrogen...

Embodiment 3

[0042] (1) Pretreatment step: put 5g graphite in 25ml Fe 2+ with H 2 o 2 In the mixed aqueous solution, where Fe 2+ with H 2 o 2 The molar ratio is 1:50, the pH value of the solution is 2, the ultrasonic power is 800W, and the treatment time is 3h. Then the graphite pretreatment product is filtered and washed;

[0043](2) Intercalation and stripping step: put 4.6g of the graphite pretreated product obtained in step (2) into 20ml of tetraethylammonium bromide aqueous solution for intercalation and stripping, the mechanical stirring rate is 200rpm, the ultrasonic power is 800W, and the treatment time is 120min , obtain multilayer graphene through filtering and washing;

[0044] (3) Repeat the pretreatment and intercalation stripping process of the multilayer graphene twice, and finally place the washed, filtered and dried product in a high-temperature reducing atmosphere (the volume ratio of hydrogen to argon is 4:96; reduction The flow rate of the protective atmosphere i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com