Preparation method of bismuth hydroxide

A technology of bismuth hydroxide and bismuth oxide, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, inorganic chemistry, etc. Unstable catalytic performance and other problems, to achieve the effect of improving catalytic performance, small particle size, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

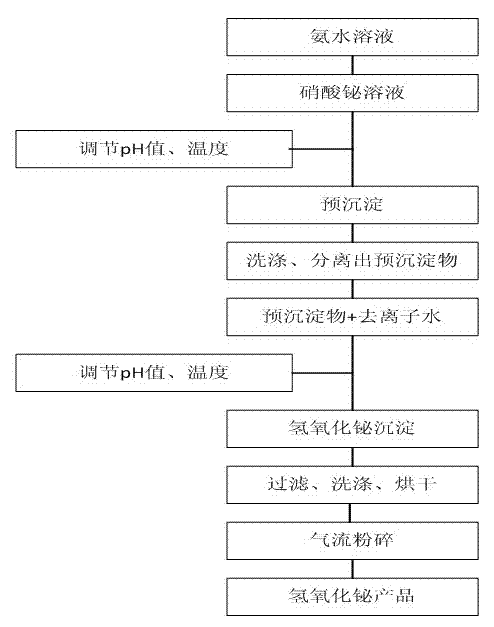

Method used

Image

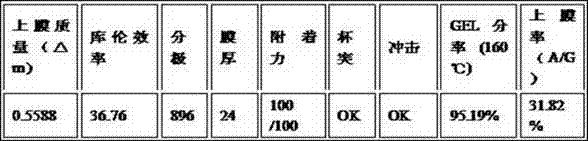

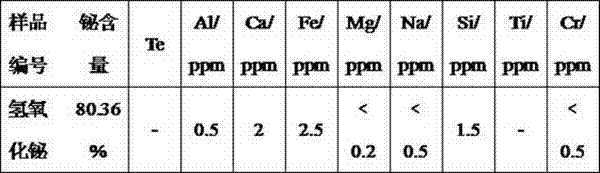

Examples

preparation example Construction

[0023] A basic preparation method of bismuth hydroxide of the present invention, the method steps are,

[0024] (1) Solution preparation

[0025] bismuth oxide Bi 2 o 3 and concentrated nitric acid with a concentration above 10mol / L to prepare a concentration of 0.15~2mol / LBi(NO 3 ) 3 solution;

[0026] Use ammonia water and deionized water with a mass content of more than 25wt% to prepare an ammonia solution with a mass content of 2wt%~25wt%, wherein the ammonia solution contains NH 4 + with Bi 3+ molar ratio to NH 4 + : Bi 3+ =3~12:1;

[0027] Add dispersant to deionized water to obtain dispersant solution, dispersant addition is relative to bismuth oxide Bi 2 o 3 The mass percentage of the added amount is 0.001%~5%;

[0028] (2) Pre-precipitation

[0029] Under stirring conditions, to bismuth nitrate Bi(NO 3 ) 3 Add the above dispersant solution to the solution, and add bismuth nitrate Bi(NO 3 ) 3 The mass added to the solution is bismuth nitrate Bi(NO 3...

Embodiment 1

[0040] Add one or more of 0.005g of polyethylene glycol, polyvinyl alcohol, propanol, glycerin, sodium dodecylsulfonate, and cetyltrimethylammonium bromide into 50ml of deionized water to prepare a dispersion dispersant solution, the amount of dispersant added relative to bismuth oxide Bi 2 o 3 The added amount is 0.001%;

[0041] 466g bismuth oxide Bi 2 o 3 Be dissolved in the concentrated nitric acid of 621ml65wt%, add above-mentioned dispersant solution and deionized water and be mixed with the bismuth nitrate Bi(NO of 0.15mol / L 3 ) 3 solution;

[0042] 780ml ammoniacal liquor is mixed with deionized water and is mixed with the ammoniacal solution that concentration is 25wt%;

[0043] Add the prepared ammonia solution to bismuth nitrate Bi(NO 3 ) 3solution, the flow rate of the ammonia solution is 3000m / min, when the pH value of the solution is adjusted to 0.5, stop adding the ammonia solution, continue to stir for 10h, after standing for precipitation, pour out the...

Embodiment 2

[0047] Add one or more of 0.045g of polyethylene glycol, polyvinyl alcohol, propanol, glycerin, sodium dodecylsulfonate, and cetyltrimethylammonium bromide to 50ml of deionized water to prepare a dispersion dispersant solution, the amount of dispersant added relative to bismuth oxide Bi 2 o 3 The added amount is 0.01%;

[0048] 466g bismuth oxide Bi 2 o 3 Dissolve in the concentrated nitric acid of 621ml65wt%, add above-mentioned dispersant solution and deionized water and be mixed with bismuth nitrate Bi(NO 3 ) 3 solution;

[0049] 780ml ammoniacal liquor is mixed with deionized water and is mixed with the ammoniacal solution that concentration is 10wt%;

[0050] Add the prepared ammonia solution to bismuth nitrate Bi(NO 3 ) 3 solution, the flow rate of the ammonia solution is 10ml / min, adjust the pH value of the solution to 3, stop adding the ammonia solution, continue to stir for 2h, after standing for precipitation, pour out the supernatant, continue to add deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com