Recycled oily sludge recovery treatment washing liquid and treatment method

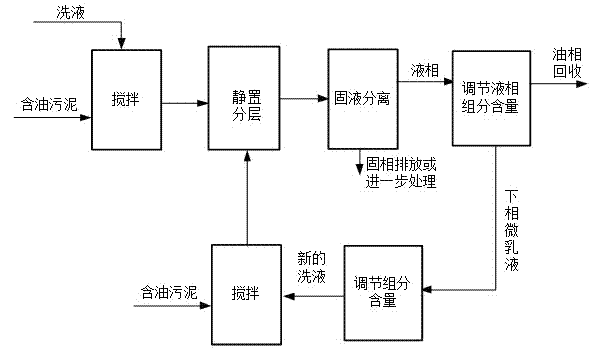

A treatment method and resource-based technology, which is applied in the treatment of oily sludge and the lotion field of resourceful treatment of oily sludge, can solve the problems of unconsidered solvent recovery, high treatment costs, solvent waste, etc., to avoid energy consumption , reduce processing costs, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The oily sludge used in this example was taken from a sludge storage tank of an oil refinery, and was treated by the method described in the present invention after pressure filtration and dehydration. The oil, water and sand contents of the oily sludge used are shown in Table 1. After analysis, it was found that the distillation range of the oil in the oily sludge was in the range of 150-290°C; 50g of the oily sludge was weighed.

[0026] ① Preparation of lotion: the lotion is composed of 1.0wt% anionic surfactant sodium dodecyl sulfate (SDS), 2.7wt% electrolyte HCl, 1.0wt% n-amyl alcohol and 95.3% water;

[0027] ②Removal of mud and sand: Weigh 100g of lotion according to the ratio of lotion to oily sludge mass ratio of 2:1, wash the aforementioned oily sludge at room temperature (about 23°C), stir for 10 minutes, and let it stand for separation. After layering, the solid phase was filtered out; dried at 105°C to constant weight, the oil content in the dry solid phase...

Embodiment 2

[0034] The oily sludge used in this example was taken from a sludge storage tank of an oil refinery, and was treated by the method described in the present invention after pressure filtration and dehydration. The oil, water and sand contents of the oily sludge used are shown in Table 1. After analysis, it was found that the distillation range of the oil in the oily sludge was in the range of 150-290°C; 50g of the oily sludge was weighed.

[0035]① Preparation of lotion: the lotion is composed of 2.4wt% anionic surfactant sodium dodecylbenzenesulfonate (SAS), 3.0wt% electrolyte HCl, 1.0wt% n-pentanol and 93.6% water;

[0036] ②Removal of mud and sand: Weigh 100g of lotion according to the ratio of lotion to oily sludge mass ratio of 2:1, wash the aforementioned oily sludge at room temperature (about 23°C), stir for 10 minutes, and let stand to separate. After layering, the solid phase was filtered out; dried at 105°C to constant weight, the oil content in the dry solid phase wa...

Embodiment 3

[0043] The oily sludge used in this example was taken from a sludge storage tank of an oil refinery, and was treated by the method described in the present invention after pressure filtration and dehydration. The contents of oil, water and sand in the oily sludge used are shown in Table 4. After analysis, it was found that the distillation range of the oil in the oily sludge was in the range of 230-370°C; 50g of the oily sludge was weighed.

[0044] Contents of oil, water and sand in the oily sludge in Table 4 Example 3

[0045] Oil content, wt%

Moisture content, wt%

Sand content, wt%

15.43

67.12

17.45

[0046] ① Preparation of lotion: the lotion is composed of 3.3wt% anionic surfactant sodium dodecyl sulfate (SDS), 1.1wt% cationic surfactant cetyltrimethylammonium bromide (CTAB), 1wt% The electrolyte HCl, the n-butanol of 3.1wt% and the water composition of 91.5%;

[0047] ②Removal of mud and sand: Take 125g of lotion according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com