Method for separating and extracting sterol from wool fat

A lanolin and sterol technology, applied in the direction of steroids, organic chemistry, etc., can solve the problems of difficult control of solvent selection and extraction condition parameters, low product separation purity, expensive molecular distillation equipment, etc., to facilitate industrial production, production The effect of high efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

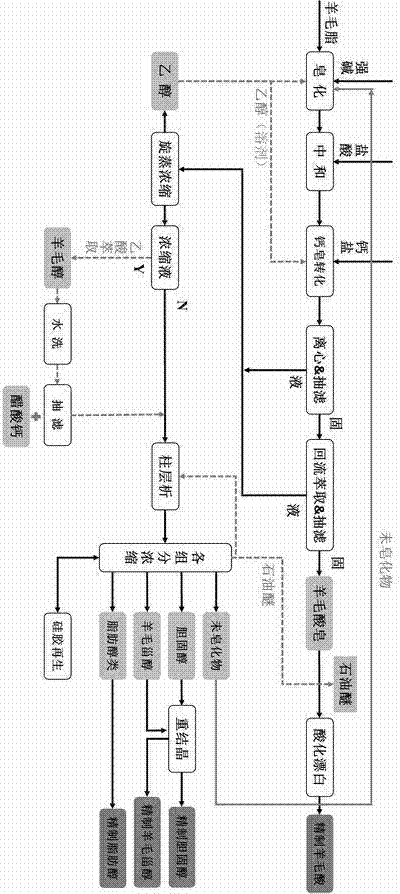

Method used

Image

Examples

Embodiment 1

[0030] 1. Weigh 25.000 g of lanolin (containing about 11% cholesterol), put it into a 250 mL three-necked bottle, add 150 mL of ethanol, 2.679 g of sodium hydroxide and 10 mL of deionized water, and heat to reflux temperature (80 °C). The reaction was carried out with mechanical stirring for 3-8 hours, and a brown-black mixed solution was obtained at the end of the reaction.

[0031] 2. Reduce the temperature of the reaction solution to 40~55°C, and adjust the pH value of the reaction solution to about 8.5~9, weigh 0.5 times the molar amount (relative to the amount of sodium hydroxide) of calcium chloride, and stir for 1~2 hours. The color of the reaction solution gradually becomes lighter, and a dark yellow mixture is obtained (a black residue will be obtained above 70°C, which is not conducive to the reaction).

[0032] 3. After the mixture was filtered with suction, the residue was extracted with absolute ethanol (200 mL×3) to obtain a khaki calcium soap powder, and all the...

Embodiment 2

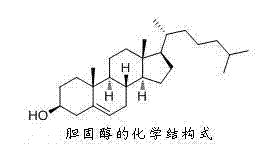

[0039] Operations were the same as steps 1-7 of Example 1 before the recrystallization step. Heat the obtained crude cholesterol to reflux and dissolve in ethyl acetate (8mL / g). When the solution is clear, add petroleum ether drop by drop. When adding petroleum ether just makes the solution cloudy, heat until clear and cool to crystal. Precipitate, finally obtain 2.07g cholesterol, purity 92.2%.

Embodiment 3

[0041] Operations were the same as steps 1-7 of Example 1 before the recrystallization step. Heat the obtained crude cholesterol to reflux and dissolve it in absolute ethanol (5mL / g). When the solution is clear, add water drop by drop. When adding petroleum ether just makes the solution cloudy, heat to clear and cool to crystals. , and finally obtained 2.21g of cholesterol with a purity of 93.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com