Water-soluble anionic acrylic resin composition for extinction and preparation method thereof

An anionic acrylic acid and resin composition technology, applied in the direction of coating, can solve the problems of poor acid resistance, alkali resistance, poor covering, affecting the storage stability of the coating, difficult to disperse evenly, etc., to achieve controllable gloss, good matting effect, and storage. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

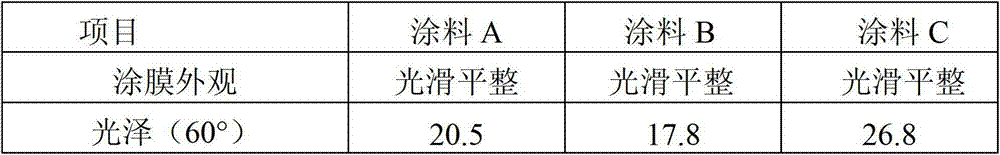

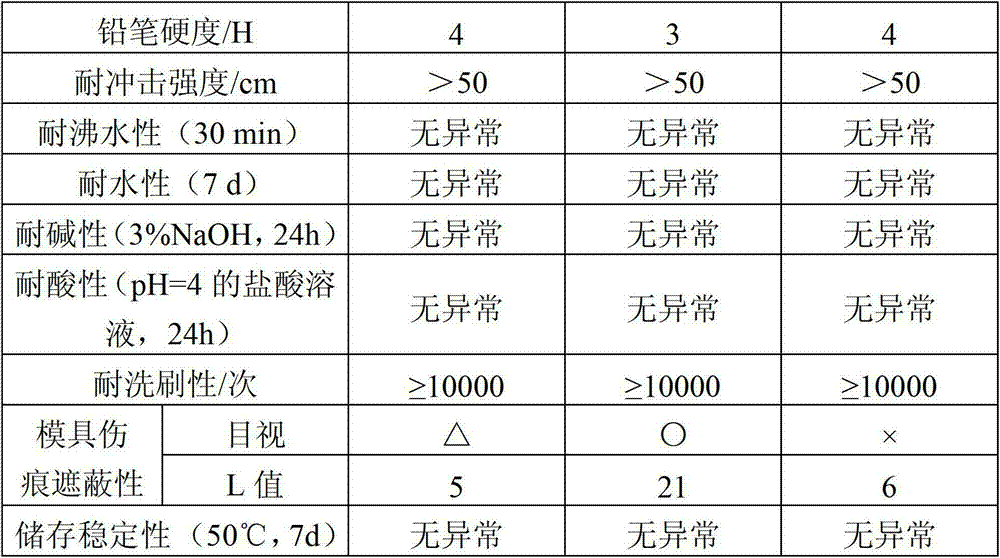

Examples

Embodiment 1

[0041] A water-soluble anionic acrylic resin composition for matting and a preparation method thereof, comprising the following steps:

[0042](1) Preparation of organosilicon-modified silica dispersion: mix ethyl orthosilicate: ethanol: water in a ratio of 4:15:1, heat up to 50°C, and adjust the pH of the system with 0.1mol / L hydrochloric acid To 3, maintain the temperature and continue the reaction for 8h under the condition of mechanical stirring, that is, SiO 2 Alcohol sol, prepared in SiO 2 Add 3.0 g of vinyltriethoxysilane to the alcohol sol, condense and reflux for 2 hours under the condition of heating in a water bath at 75° C., and cool to obtain a silicone-modified silica dispersion.

[0043] (2) 5 parts by mass of hydroxyethyl methacrylate, 8 parts by mass of methyl methacrylate, 6 parts by mass of butyl methacrylate, 5 parts by mass of methacrylic acid, 12 parts by mass of butyl acrylate, 6 parts by mass of benzene Ethylene monomers are mixed evenly and set aside...

Embodiment 2

[0047] (1) The preparation method of the organosilicon-modified silica dispersion is the same as step (1) of Example 1.

[0048] (2) Mix 6 parts by mass of hydroxyethyl methacrylate, 7 parts by mass of methyl methacrylate, 8 parts by mass of butyl methacrylate, 6 parts by mass of methacrylic acid, 15 parts by mass of butyl acrylate, and 7 parts by mass of benzene Ethylene monomers are mixed evenly and set aside;

[0049] (3) Under the protection of nitrogen, dissolve 1.103 parts by mass of sodium lauryl sulfate and 0.368 parts by mass of polyoxyethylene-8-octylphenyl ether compound emulsifier in 115 parts by mass of deionized water, and then add In a four-necked round-bottomed flask with a stirrer, a thermometer and a separating funnel, add 12.25 parts by mass of the acrylate monomer mixture of step (2), 1.4 parts by mass of a 5% (mass fraction) initiator potassium persulfate solution, During rapid stirring, the temperature was raised to 80°C, and after 1 hour of reaction, th...

Embodiment 3

[0052] (1) Preparation of organosilicon-modified silica dispersion: mix ethyl orthosilicate: ethanol: water in a ratio of 3:12:2, heat up to 75°C, and adjust with hydrochloric acid (0.1mol / L) The pH of the system is 4, and the temperature is maintained under the condition of mechanical stirring for 12 hours to obtain SiO 2 Alcohol sol, prepared in SiO 2 Add 4.8 g of vinyltriethoxysilane to the alcohol sol, condense and reflux for 3 hours under the condition of heating in a water bath at 80° C., and cool to obtain a silicone-modified silica dispersion.

[0053] (2) 10 parts by mass of hydroxyethyl methacrylate, 18 parts by mass of methyl methacrylate, 13 parts by mass of butyl methacrylate, 12 parts by mass of methacrylic acid, 30 parts by mass of butyl acrylate, 12 parts by mass of benzene Ethylene monomers are mixed evenly and set aside;

[0054] (3) Under the protection of nitrogen, dissolve 2.138 parts by mass of sodium lauryl sulfate and 0.712 parts by mass of polyoxyeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com