Preparation method of three-dimensional cell culture support and culture device of three-dimensional cells

A three-dimensional cell and culture scaffold technology, which is applied in the preparation of cell culture scaffolds, the preparation of three-dimensional cell culture scaffolds, and the field of cell culture devices to achieve the effects of good growth, maintenance and proliferation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In this embodiment, the preparation method of the three-dimensional cell culture scaffold includes the following steps:

[0044] a. Weigh 1~10g of polymer and dissolve it in 10~100ml of organic solvent to form a polymer solution. The polymer includes polyvinylchloride (PVC), etc., and the organic solvent includes tetrahydrofuran, etc.

[0045]b. Weigh 0~500mg of plasticizer, add it into the above polymer solution, and mix well. Plasticizers include dioctyl phthalate, dioctyl sebacate, and the like.

[0046] c. Weigh 0~2g of hydroxyapatite glue nanoparticles; 0~2g of silver nanoparticles; 0~2g of zinc oxide nanoparticles; 0~2g of chitosan nanoparticles, join in the solution processed through step b, mix Evenly, the spinning dope is obtained. Wherein the particle size range of the above-mentioned nanoparticles is: 10-500nm.

[0047] d. Inject the spinning stock solution into the electrospinning equipment, perform electrospinning treatment, and obtain spinning on the re...

Embodiment 1

[0056] Example 1: Preparation of three-dimensional cell culture scaffold by electrospinning method

[0057] In this specific embodiment, the polymer is: polyvinylchloride (PVC); the organic solvent is: tetrahydrofuran; and the plasticizer is: dioctyl phthalate.

[0058] Take 5g of polyvinyl chloride powder and dissolve it in 65ml of tetrahydrofuran. According to the experiment, an appropriate amount of plasticizer dioctyl phthalate 275mg can be added. 1.2g of 500nm hydroxyapatite glue nanoparticles, 0.9g of silver nanoparticles, 1.5g of zinc oxide nanoparticles, 0.8g of chitosan nanoparticles, and mix them uniformly. Then, under the conditions of voltage 45kV, receiving distance 17cm, sampling speed 1.8ml per hour, and receiving screen made of aluminum foil (roller can also be used to collect and spin), an orderly spinning is produced, and then the spinning is dried, that is Three-dimensional cell scaffolds for cell culture.

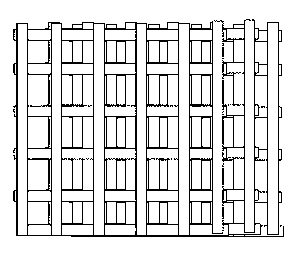

[0059] Such as image 3 Shown is a schematic di...

Embodiment 2

[0060] Example 2: Preparation of three-dimensional cell culture scaffold by using porogen pore-making method

[0061] In this specific embodiment, the first matrix material is: L-polylactic acid; the second matrix material is: addition polycaprolactone; the organic solvent is: N,N-dimethylformamide; the acidic solution is hydrofluoric acid.

[0062] Weigh 38g of L-polylactic acid, add 42g of polycaprolactone and 7.5g of N,N-dimethylformamide. Add L-polylactic acid and polycaprolactone into N, N-dimethylformamide, and mix well. Then, add 0.8g of hydroxyapatite glue nanoparticles of 10-500nm, 1.1g of zinc oxide nanoparticles, 0.5g of silver nanoparticles, and 1.3g of chitosan nanoparticles and mix well, and add the compound with a diameter of 10-500nm. The 50-micron silica particles are mixed into various shapes, and after drying, they are soaked in hydrofluoric acid to dissolve the silica particles to obtain a round-hole cell culture scaffold.

[0063] Such as Figure 4 Show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com