Three-waste-free preparation method for bifenthrin

A technology of bifenthrin and three wastes, which is applied in the field of bifenthrin synthesis, can solve the problems of excessive waste water, low yield, and serious discharge of three wastes, and achieve the effects of simple process, high total yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A, esterification reaction prepares methyl kung fu acid

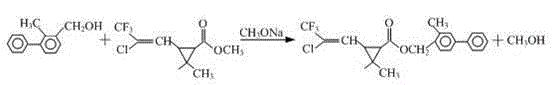

[0023] The esterification reaction formula is as follows:

[0024]

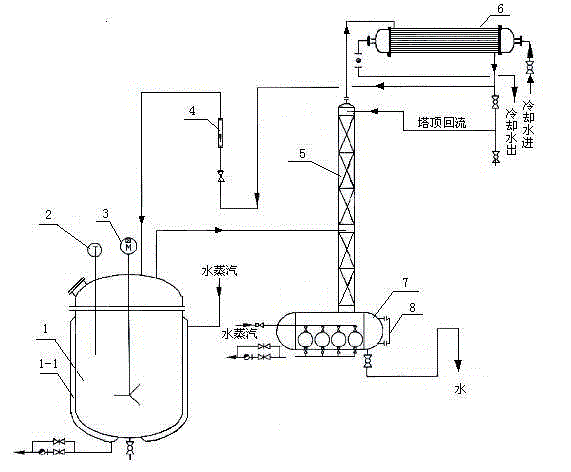

[0025] See figure 1 , put into 500kg kungfu acid, 500kg methanol, 5kg sulfuric acid in the esterification reactor 1, pass into the interlayer 1-1 to heat with steam, open the stirrer; control the temperature of the material in the esterification reactor 1 to rise to 65 ° C, Part of methanol participates in the reaction to generate methyl kung fu acid and water, and as the reaction progresses, the temperature slowly rises to 70°C. The water generated by the esterification reaction is carried by methanol and evaporated from the top of the esterification reactor 1, and then passed into the rectification tower 5. The bottom of the rectification tower 5 is heated by steam from the reboiler 7, the reflux ratio is adjusted in time, and the temperature at the top of the tower is controlled at 64.5°C. The methanol distilled from the top of the towe...

Embodiment 2

[0032] In the esterification reaction still, drop into 500kg kongfuic acid, 700kg methyl alcohol, 5kg sulfuric acid, temperature of reaction is 60~65 ℃, reacts 21 hours, other conditions are identical with embodiment 1 step a, make colorless transparent methyl kongic acid liquid. Yield 97.9%, content ≥99.3% (GC normalization method).

[0033] In the transesterification reaction, feed materials according to step b of Example 1, control the negative pressure in the transesterification reactor to 0.079-0.081MPa, and the temperature is 59-61°C, and the other conditions are the same as step b of Example 1 to obtain white powder Bifenthrin, with a content of 98.2% (GC internal standard method), a conversion rate of 94%, and a total yield of 98.5%.

Embodiment 3

[0035] Prepare the solid acid catalyst as follows: Soak the coarse-porous microsphere silica gel with an average pore diameter of 8.0-12.0nm in a sulfuric acid solution with a mass concentration of 50%, and after 1 hour, bake at 100°C for 3 hours to obtain sulfuric acid-silica gel microspheres (that is, sulfuric acid solid acid supported by silica gel). Use sulfuric acid solid acid instead of the sulfuric acid in step a of Example 1 to carry out the esterification reaction. The esterification reaction temperature rises to 65°C, and then slowly rises to 75°C. After the esterification reaction is completed, the catalyst is directly filtered out and reused in the following For batch production, the filtrate is directly put into the distillation kettle (neutralization with powdery sodium carbonate is not required), and methanol is distilled off under negative pressure, and the 134-137°C / 0.095MPa fraction is collected to obtain a colorless and transparent methyl kung fu acid liquid....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com