Polyimide oligomer and liquid photoimagable solder resist ink

A technology of polyimide and oligomer, which is applied in ink, optics, optomechanical equipment, etc., can solve the problems of decreased adhesion, decreased adhesion and physical and mechanical properties, and low cross-linking density, and meets the requirements of Bending resistance, excellent adhesion fastness, high reflective whiteness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] 1) Add 16.8 grams (0.08 moles) of 4,4'-diaminodicyclohexylmethane, 20 grams (0.01 moles) of polyetheramine D-2000 (x=33) and 17.52 grams (0.12 moles) of lysine In 295 grams of m-cresol, keep the temperature at 50°C for 10 minutes to completely dissolve it;

[0076] 2) Under nitrogen protection, add 42 grams (0.2 moles) of 1,2,3,4-cyclopentane tetracarboxylic dianhydride, and react at 50°C for 30 minutes;

[0077] 3) Add 1.96 g (0.02 mol) of maleic anhydride, first react at 50°C for 30 minutes, and then react at 120°C for 2 hours;

[0078] 4) Then heat up to 200°C and react for 5 hours;

[0079] 5) After the reaction, pour the reaction solution into anhydrous methanol to obtain a light yellow solid, wash the light yellow solid with anhydrous methanol, and then dry it at 50°C to obtain a white solid, namely polyimide Oligomer.

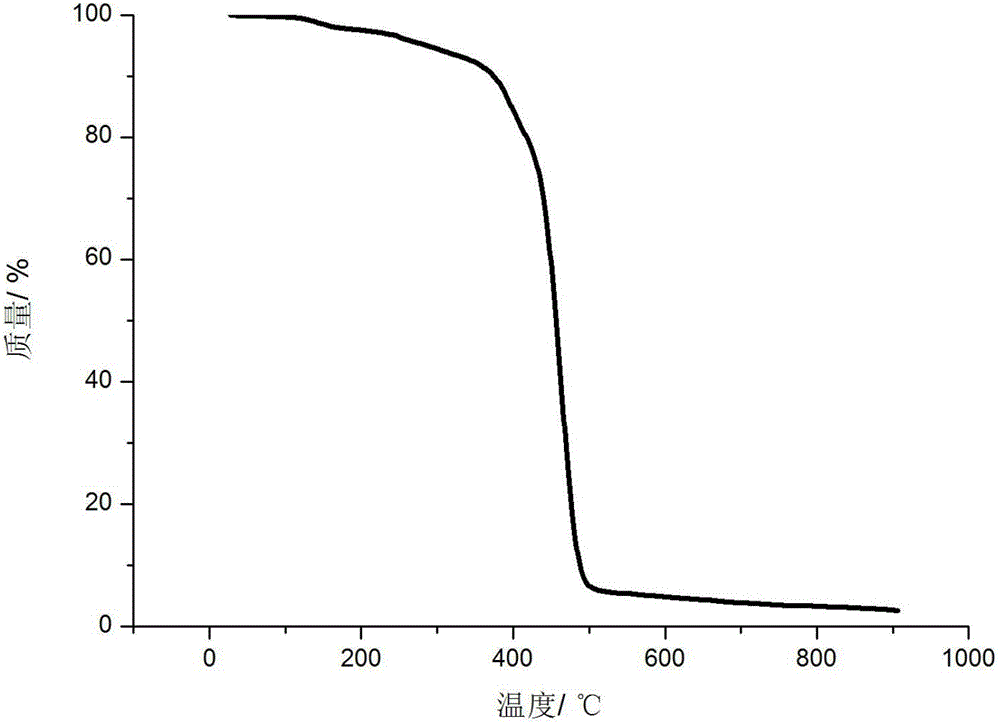

[0080] The polyimide oligomer after above-mentioned purification is carried out thermogravimetric analysis, the result is as follows figure 1...

Embodiment 2

[0095] 1) Add 8.5 grams (0.05 moles) of isophorone diamine, 20 grams (0.02 moles) of polyetheramine D-1000 (x=16) and 13.14 grams (0.09 moles) of lysine to 232 grams of N- In methylpyrrolidone, keep the temperature at 70°C for 10 minutes to completely dissolve;

[0096] 2) Under nitrogen protection, add 33.6 g (0.15 moles) of 1,2,4,5-cyclohexanetetracarboxylic dianhydride, and react at 70°C for 30 minutes;

[0097] 3) Add 1.96 g (0.02 mol) of maleic anhydride, first react at 70°C for 30 minutes, and then react at 140°C for 2 hours;

[0098] 4) Then heat up to 220°C and react for 5 hours;

[0099] After the reaction, pour the reaction solution into anhydrous methanol to obtain a light yellow solid, wash the light yellow solid with anhydrous methanol, and then dry it at 50°C to obtain a white solid, which is polyimide oligomerization thing.

[0100] Liquid photosensitive alkali developing solder resist ink:

[0101] Weight percentage ratio: photosensitive resin (polyimide ol...

Embodiment 3

[0115] 1) 8.40 g (0.04 mol) of 4,4'-diaminodicyclohexylmethane, 9.52 g (0.04 mol) of 3,3'-dimethyl-4,4'-diaminodicyclohexylmethane, polyether Amine D-400 (x=5) 16 g (0.04 mol) and lysine 20.44 g (0.14 mol) were successively added to 335 g of N-methylpyrrolidone, and kept at 60°C for 10 minutes to completely dissolve;

[0116] 2) Under nitrogen protection, add 25.48 grams (0.13 moles) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride and bicyclo[2.2.2]oct-7-ene-2,3,5,6 - 29.76 grams (0.12 moles) of tetracarboxylic dianhydride, reacted for 30 minutes at 60°C;

[0117] 3) Add 1.96 g (0.02 mol) of maleic anhydride, first react at 60°C for 30 minutes, and then react at 130°C for 2 hours;

[0118] 4) Then heat up to 180°C and react for 5 hours;

[0119] 5) After the reaction, pour the reaction solution into anhydrous methanol to obtain a light yellow solid, wash the light yellow solid with anhydrous methanol, and then dry it at 50°C to obtain a white solid, namely polyimide Oligo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com