Fermented bean product fermented by lactobacillus plantarum ST-III and alpha-glucosidase inhibitor

A technology of glucosidase and Lactobacillus plantarum, applied in the field of fermented soybean products and α-glucosidase inhibitors fermented by Lactobacillus plantarum ST-Ⅲ, can solve the problems of unstable composition, unstable, unfavorable manufacturing, etc. To achieve the effect of controlling blood sugar fluctuations and shortening the fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

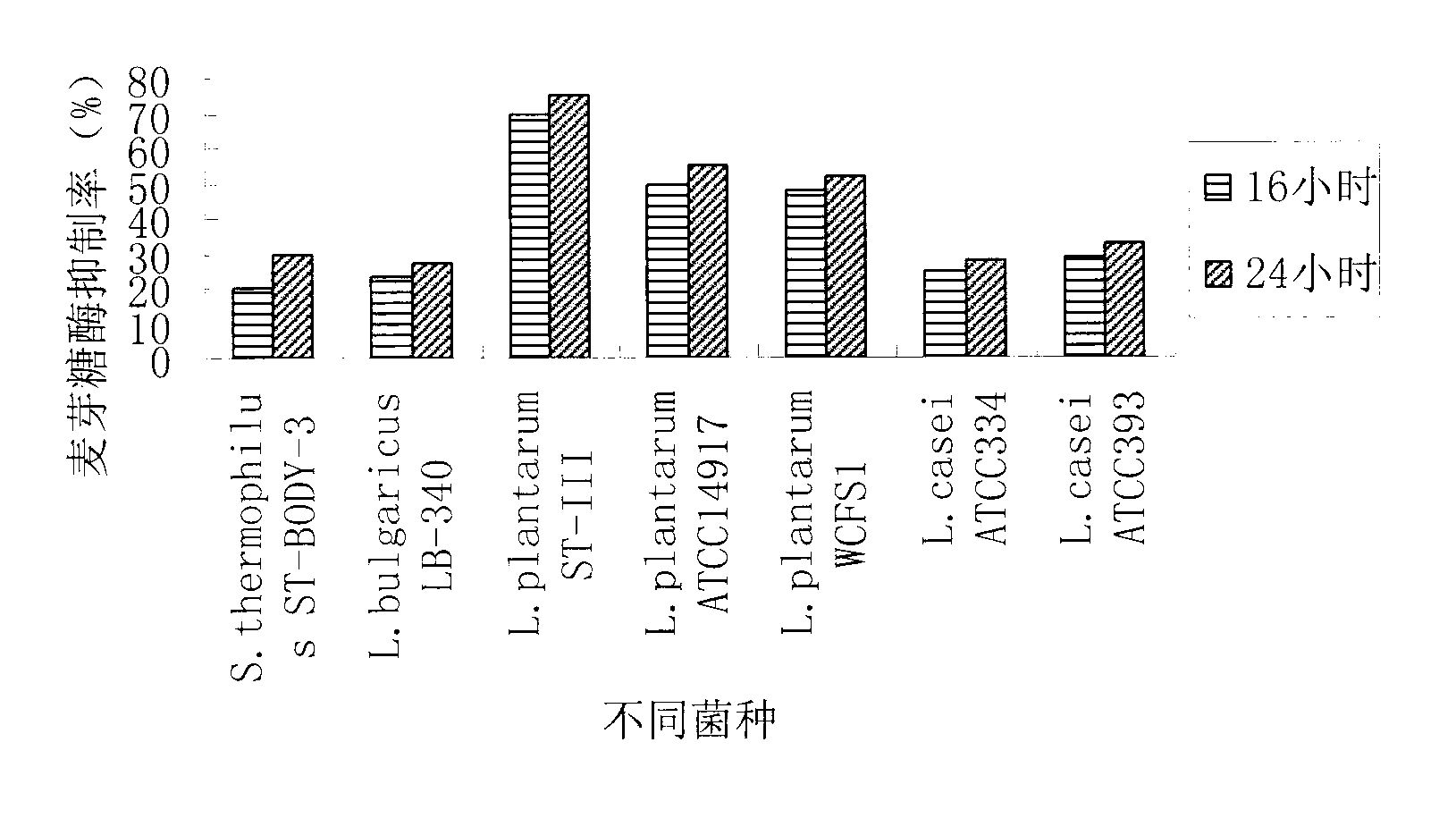

[0071] Example 1 Screening of lactic acid bacteria

[0072] Preparation of seeds (fermentation strains): respectively L.plantarum ST-III, L.plantarumATCC14917, L.plantarum WCFS1, L.bulgaricus LB-340 (provided by Danisco), L.casei ATCC334, L.casei ATCC393 Inoculated in MRS liquid (Merck Co. Germany), S.thermophilus ST-BODY-3 (provided by Ke. Hansen) was inoculated in M17 (Merck Co. Germany), cultured at 37°C for 24 hours, and the culture was centrifuged at 9,000rpm for 10 After 2 minutes, the supernatant was discarded, and the thalline was washed twice with sterile distilled water, then suspended with the sterile distilled water of the original culture volume to obtain seeds for fermentation (i.e. working starter).

[0073] Preparation of soymilk: After weighing the dried beans, add five times the mass of water and soak them at 37°C for 8 hours, discard the water, and add wet beans and water in a certain proportion to the soymilk machine to obtain the desired solid content. So...

Embodiment 2

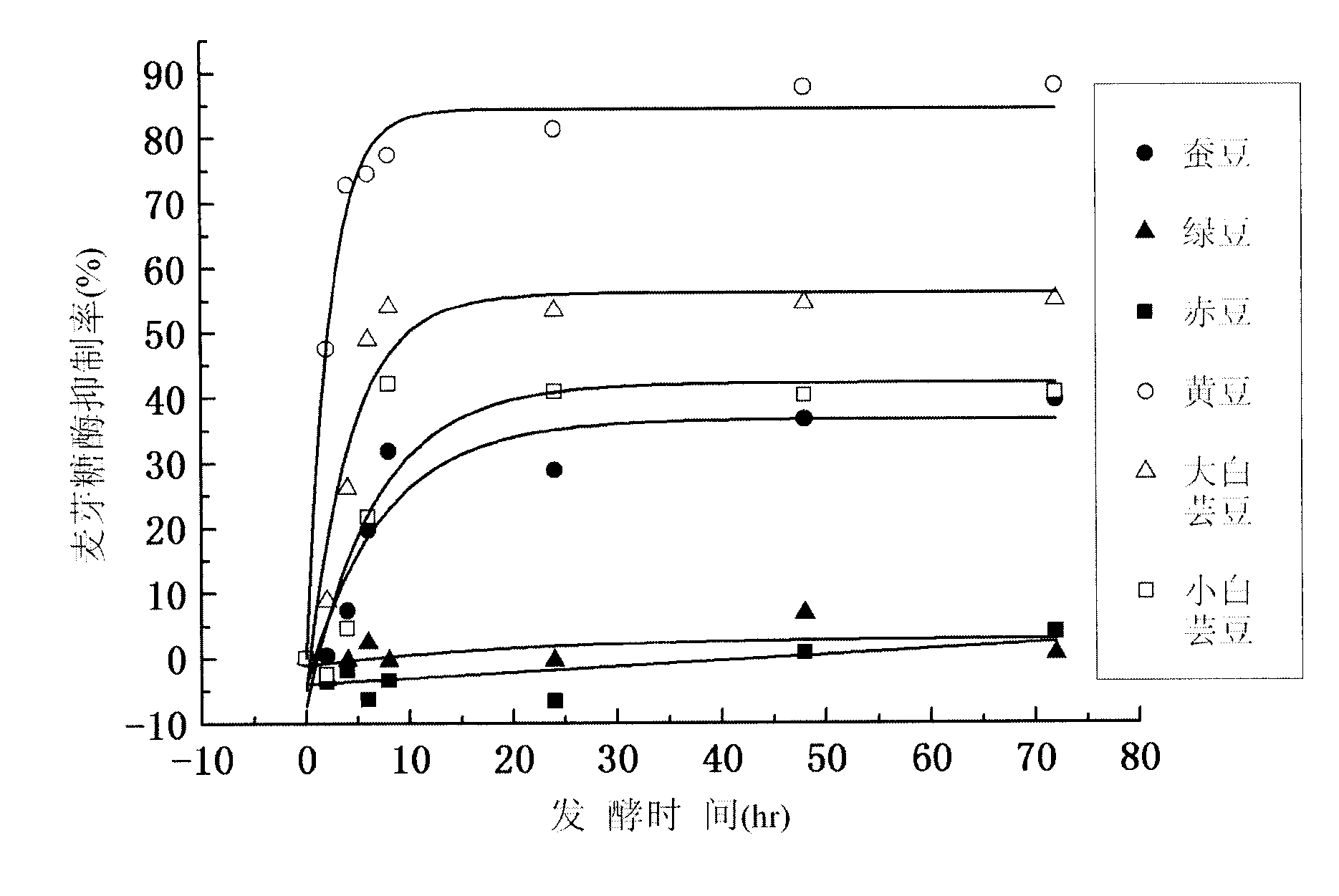

[0077] Example 2 Screening beans

[0078] Effects of Fermentation Products of Lactobacillus plantarum ST-III on Maltase Inhibitory Activity of Soymilk from Different Soybeans

[0079] Preparation of soymilk: After weighing the dried beans, add five times the mass of water and soak them at 37°C for 8 hours, discard the water, and add wet beans and water in a certain proportion to the soymilk machine to obtain the desired solid content. Soybean milk is sterilized at 118°C for 15 minutes to obtain aseptic soymilk with specified solid content concentration.

[0080]As above method, soybean, red bean, mung bean, broad bean, large white kidney bean and small white kidney bean were used to prepare sterile soybean milk with a solid content of 5% (w / w). Then insert the Lactobacillus plantarum ST-III seed (i.e. the working starter prepared in Example 1) by 2% (v / v) inoculation amount, cultivate at 37° C., and cultivate for 0 to 72 hours to obtain fermented soybean milk.

[0081] Pretr...

Embodiment 3

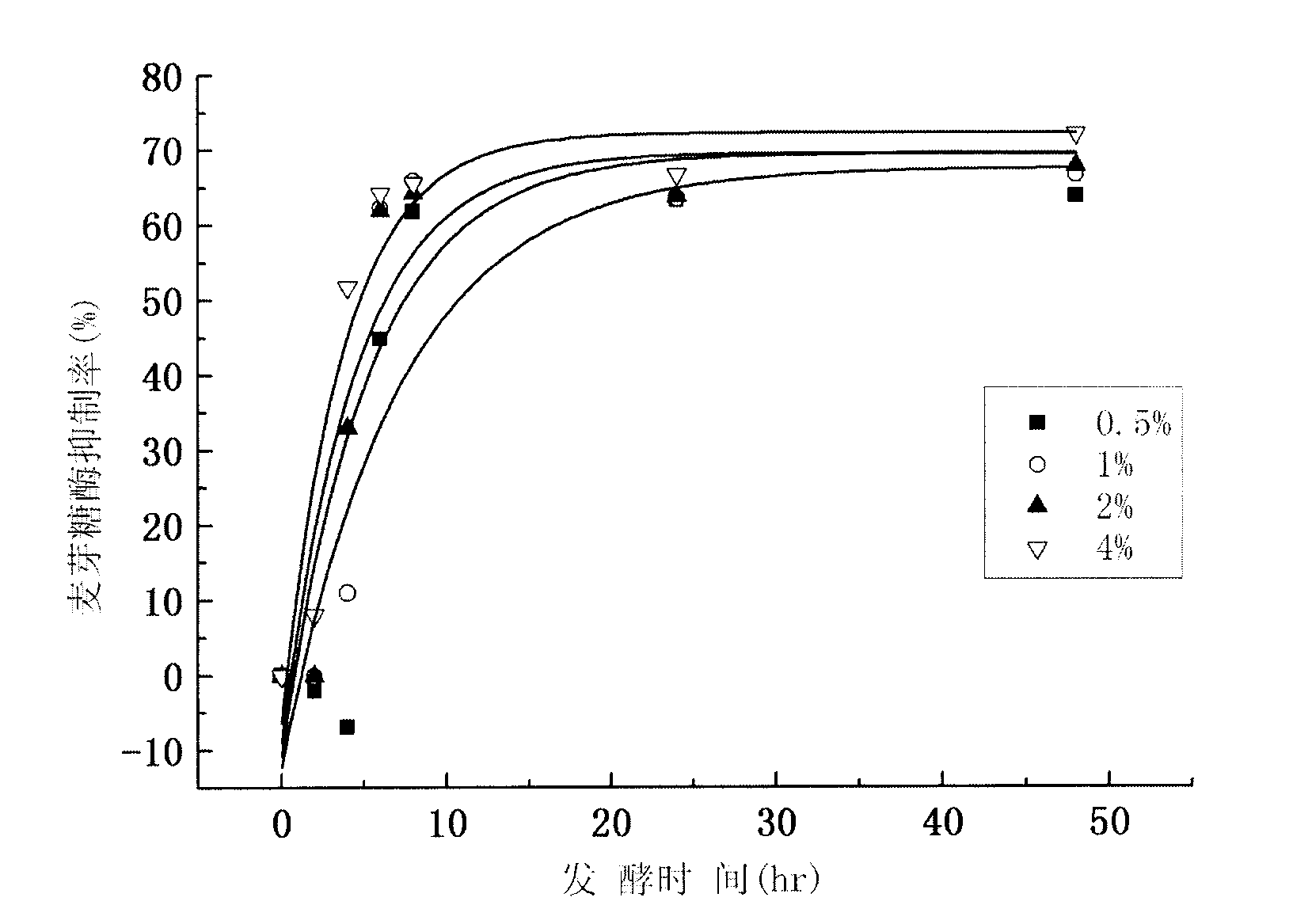

[0083] Example 3 Optimization of Fermented Soybean Milk Conditions

[0084] 1) Effect of different inoculum amounts of Lactobacillus plantarum ST-III on the inhibition of maltase activity of fermentation products

[0085] The seed of plantaractobacillus ST-III (working starter prepared by embodiment 1) is inserted into the solid content of 5% (w / In the sterilized soybean milk of w), the number of live bacteria of Lactobacillus plantarum after inoculation is 5×10 6 to 5×10 7 cfu / ml (colony forming unit per milliliter), cultivated at 37°C, and the fermented soymilk cultured for different time was pretreated to measure its inhibitory activity to maltase, sucrase and α-amylase according to the method described.

[0086] The obtained fermented soybean milk has an inhibition rate of 5-75% to maltase, the results are shown in image 3 . The inhibition rate to sucrase is 1-35%, and it has no obvious inhibitory effect on α-amylase, and the inhibition rate is 1-10%. It can be seen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com