Preparation method and applications of hyperbranched azo polymer

An azo polymer, polymer technology, applied in chemical instruments and methods, color-changing fluorescent materials, etc., can solve the problems of low response rate and degree of photoisomerization, and achieve the effect of low driving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

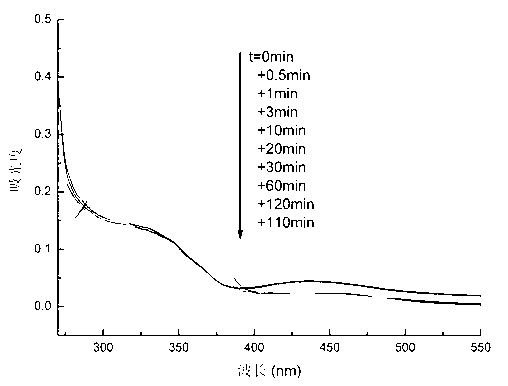

Image

Examples

Embodiment 1

[0026] Add 3g of p-nitrobenzoic acid, 9g of sodium hydroxide and 9mL of water in sequence in a 250mL three-necked flask equipped with a stirring bar, stir well and heat up to 35°C; dissolve 21g of glucose in 50mL of water, and add dropwise within 10min In the three-necked flask, the temperature was maintained at 35°C for 30 minutes, and then the temperature was lowered to 10°C and the reaction was continued for 45 minutes. Pour the reaction solution into a beaker, cool it, neutralize it with dilute hydrochloric acid to pH=0.5, then filter the mixture with suction to obtain a yellow solid; dissolve the solid with sodium hydroxide solution, add hydrochloric acid to acidify, and precipitate a solid , filtered by suction and washed with water to obtain a yellow solid, which was dried in an oven.

[0027] Add 2g of the above yellow solid, 0.45g of thionyl chloride, 2mL of N,N'-dimethylformamide and 10g of acetone into a 100mL round bottom flask, and reflux at 60°C for 9h. After th...

Embodiment 2

[0030] Add 3g of p-nitrobenzoic acid, 15g of sodium hydroxide and 60mL of water in sequence in a 250mL three-necked flask equipped with a stirring bar, stir evenly and heat up to 65°C; dissolve 27g of glucose in 50mL of water, and add it dropwise within 2 hours In the three-necked flask, the temperature was maintained at 65° C. for 2 h, and then the temperature was lowered to 20° C. and the reaction was continued for 2 h. The reaction solution was poured into a beaker, cooled, neutralized with acetic acid to pH = 7, and then the mixed solution was suction filtered to obtain a yellow solid; the solid was dissolved in ammonium bicarbonate solution, and then acidified by adding acetic acid to precipitate a solid. After suction filtration and washing with water, a yellow solid was obtained, which was dried in an oven.

[0031] Add 2g of the above yellow solid, 4.5g of thionyl chloride, 10mL of N,N'-dimethylformamide and 40g of ethanol into a 100mL round bottom flask, and reflux at...

Embodiment 3

[0034] Add 3g of p-nitrobenzoic acid, 11g of sodium hydroxide and 40mL of water successively into a 250mL three-necked flask equipped with a stirring bar, stir well and heat up to 50°C; dissolve 25g of glucose in 50mL of water, and add dropwise within 30min In the three-necked flask, the temperature was maintained at 50° C. for 1 h, and then the temperature was lowered to 15° C. and the reaction was continued for 1 h. Pour the reaction solution into a beaker, cool it, and neutralize it with acetic acid to pH=5, then filter the mixture with suction to obtain a yellow solid; dissolve the solid with potassium carbonate solution, add acetic acid to acidify, and precipitate a solid After filtering and washing with water, a yellow solid was obtained, which was dried in an oven.

[0035] Add 2g of the above yellow solid, 1.8g of thionyl chloride, 5mL of N,N'-dimethylformamide and 20g of ethyl acetate into a 100mL round bottom flask, and reflux at 65°C for 11h. After the reaction, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com