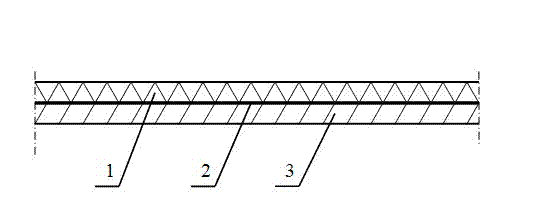

High thermal conductivity epoxy few adhesive mica tape and preparation method of high thermal conductivity epoxy few glue mica tape

A low-glue mica tape, high thermal conductivity technology, applied in chemical instruments and methods, lamination, insulators, etc., can solve the problems of reducing dielectric properties and mechanical properties, mica tapes do not have high thermal conductivity, and aging of insulating structural materials, etc. Achieve the effect of saving production equipment costs, reducing harmful gas emissions and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

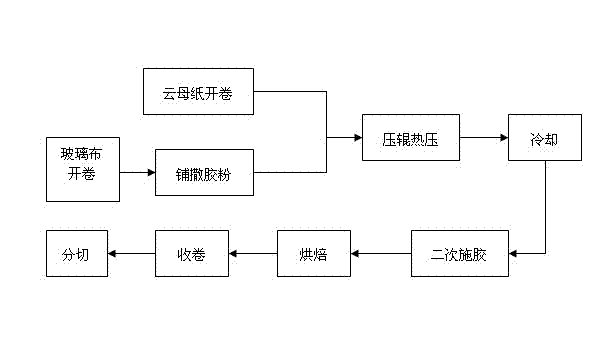

[0024] The thermally conductive filler is made of nanometer (particle size 30-70nm) aluminum nitride and micron (particle size 1-40μm) aluminum oxide, which is uniformly mixed at a mass ratio of 2:1, and the silane coupling agent KH-560 is used as the thermal conductive filler 1% of the mass, and mixed with absolute ethanol to prepare a solution with a mass ratio of 1:4. Add the thermal conductive filler to the solution and disperse at a high speed of 2000r / min for 1h, then ball mill at 4000r / min for 1h, and then vacuum Suction filter and dry in an oven at 100°C, and seal for later use.

[0025] Heat the polyesterimide-modified epoxy adhesive to 80°C-90°C, add 20% by volume of thermally conductive filler, disperse at a speed of 1500r / min for 1 hour to evenly disperse the thermally conductive filler in the adhesive, and cool the adhesive to Crush into rubber powder after room temperature.

[0026] Uncoil the non-alkali glass cloth for electrical purposes with a thickness of 0....

Embodiment 2

[0028] The thermally conductive filler is made of nanometer (particle size 30-70nm) α-phase crystal aluminum oxide and micron (particle size 1-40μm) aluminum oxide, which are uniformly mixed at a mass ratio of 3:2, and the silane coupling agent KH -550 is 3.5% of the mass of the thermally conductive filler, and it is mixed with anhydrous ethanol to prepare a solution with a mass ratio of 1:4. Add the thermally conductive filler to the solution and disperse at a high speed of 2000r / min for 1h, and then disperse at 4000r / min Ball milled for 3 hours, vacuum filtered and dried in an oven at 100°C, sealed for later use.

[0029] Heat the polyester modified epoxy adhesive to 80°C-90°C, add 30% by volume of thermally conductive filler, disperse at a speed of 1500r / min for 2 hours to disperse the thermally conductive filler evenly in the adhesive, cool the adhesive to room temperature and pulverize into powder.

[0030] Unroll the non-alkali glass cloth for electrical purposes with a...

Embodiment 3

[0033]The thermal conductive filler is mixed with nanometer (particle size 30-70nm) grade spherical silica and nanometer (particle size 30-70nm) aluminum nitride at a mass ratio of 1:1, and then mixed with micron (particle size 1-40μm) nitrogen Boron, mix uniformly according to the mass ratio of 5:4, take the silane coupling agent KH-550 as 5% of the mass of the thermally conductive filler, and prepare a solution with a mass ratio of 1:4 with absolute ethanol, and add the thermally conductive filler to the Disperse in the solution at a high speed of 2000r / min for 1h, then ball mill at 4000r / min for 5h, vacuum filter and dry in an oven at 100°C, seal for later use.

[0034] Heat the bisphenol A type epoxy resin and polyester modified epoxy adhesive with a mass ratio of 1:4 to 80°C-90°C, add 40% by volume of thermally conductive filler, and disperse the thermally conductive filler at a speed of 1500r / min for 2 hours. Disperse evenly in the adhesive, cool the adhesive to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com