Method for preparing cone-shaped structure on gallium phosphide (GaP) surface

A cone-shaped and equipment technology, which is applied in the preparation and application of three-dimensional micro-nano structures, can solve problems such as the inability to realize high-aspect-ratio cone-shaped structures, and the inability to effectively control cone-shaped structures, and achieve high-depth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

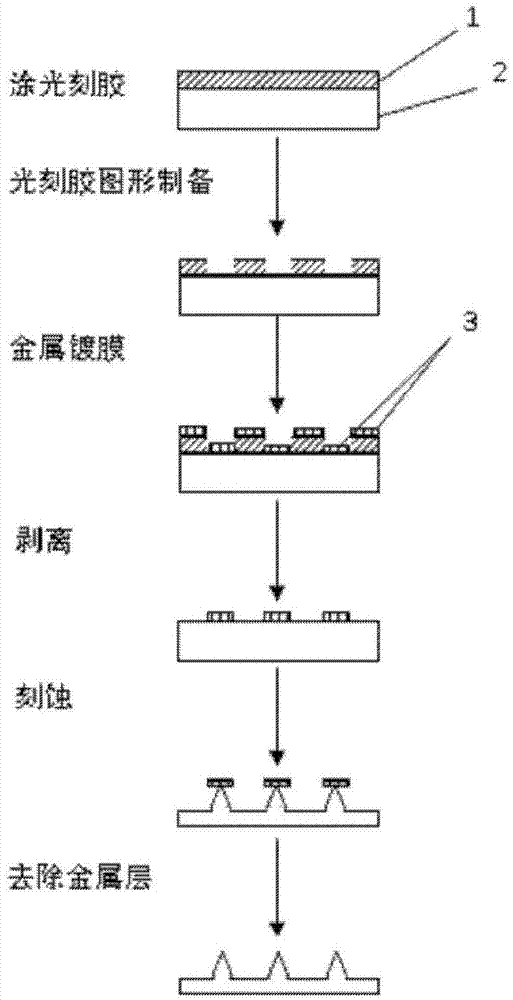

[0029] Embodiment 1: as figure 1 A flowchart showing the preparation of a tapered structure on the surface of GaP using photoresist pattern preparation technology, metal coating, stripping and etching processes in the embodiment of the present invention includes the following steps:

[0030] Step S1: Spin-coat photoresist on the surface of the GaP sample, and use one of UV exposure, electron beam exposure, laser interference exposure, laser direct writing, and nanoimprinting techniques to prepare a photoresist with a porous structure on the photoresist Array pattern, obtain the sample with photoresist pattern;

[0031] Step S2: Put the sample with photoresist pattern into one of thermal evaporation equipment, electron beam evaporation equipment, and sputtering equipment for coating, and grow a metal among chromium, aluminum, gold, titanium, and nickel as the engraved Etch the mask to obtain a sample with a metal layer.

[0032] Step S3: putting the sample with the metal laye...

Embodiment 2

[0035] Embodiment 2: Utilizing the preparation method of the present invention, adopting electron beam exposure, metal coating, stripping and etching techniques to prepare a cone-shaped structure on the GaP surface, specifically comprising the following steps:

[0036] Step 1) Spin-coat electron beam photoresist ZEP520 on the GaP surface, and bake the sample on a hot plate at 180°C for 2 minutes after spin-coating;

[0037] Step 2) using electron beam exposure equipment to prepare a circular hole array photoresist pattern on the photoresist;

[0038] Step 3) put the sample with photoresist pattern prepared in step 2) into a thermal evaporation device to grow a 50nm thick metal chromium film;

[0039] Step 4) putting the sample after growing the metal layer into an acetone solution for stripping to obtain a chromium frustum array;

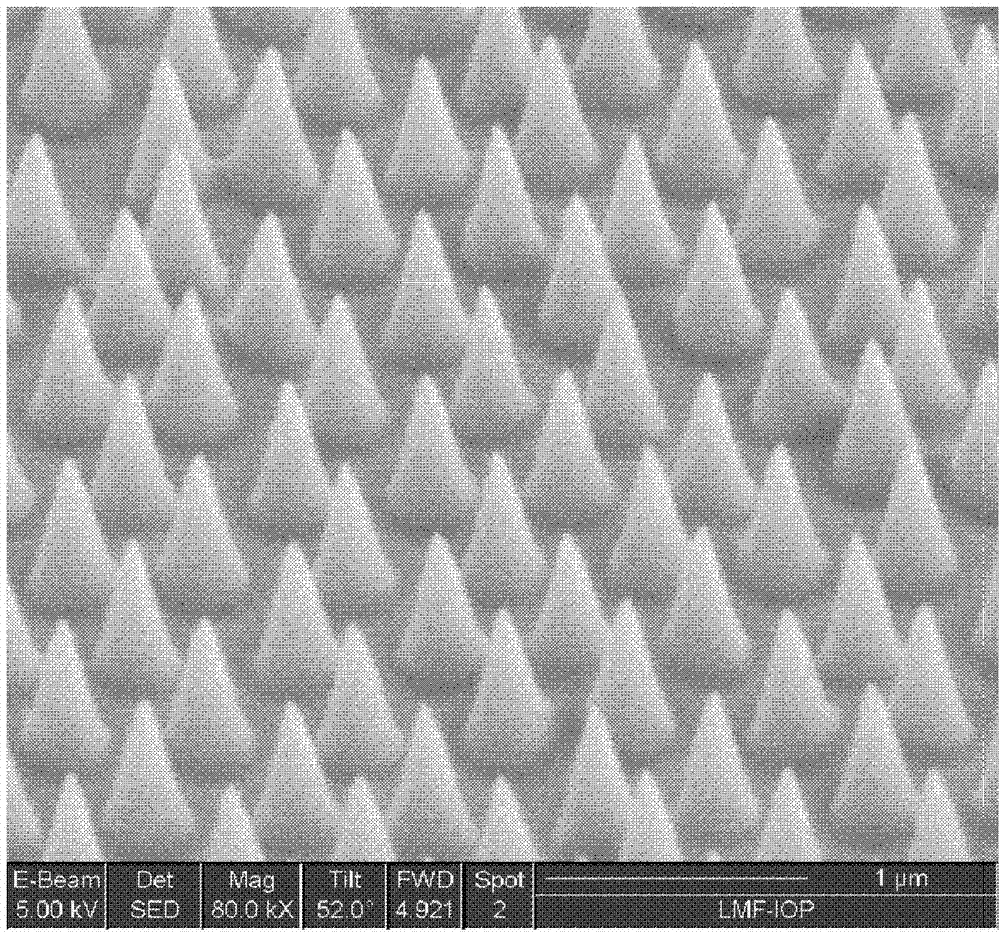

[0040] Step 5) put the sample obtained in step 4) into an inductively coupled plasma etching device, and the etching parameters used are: chlorine...

Embodiment 3

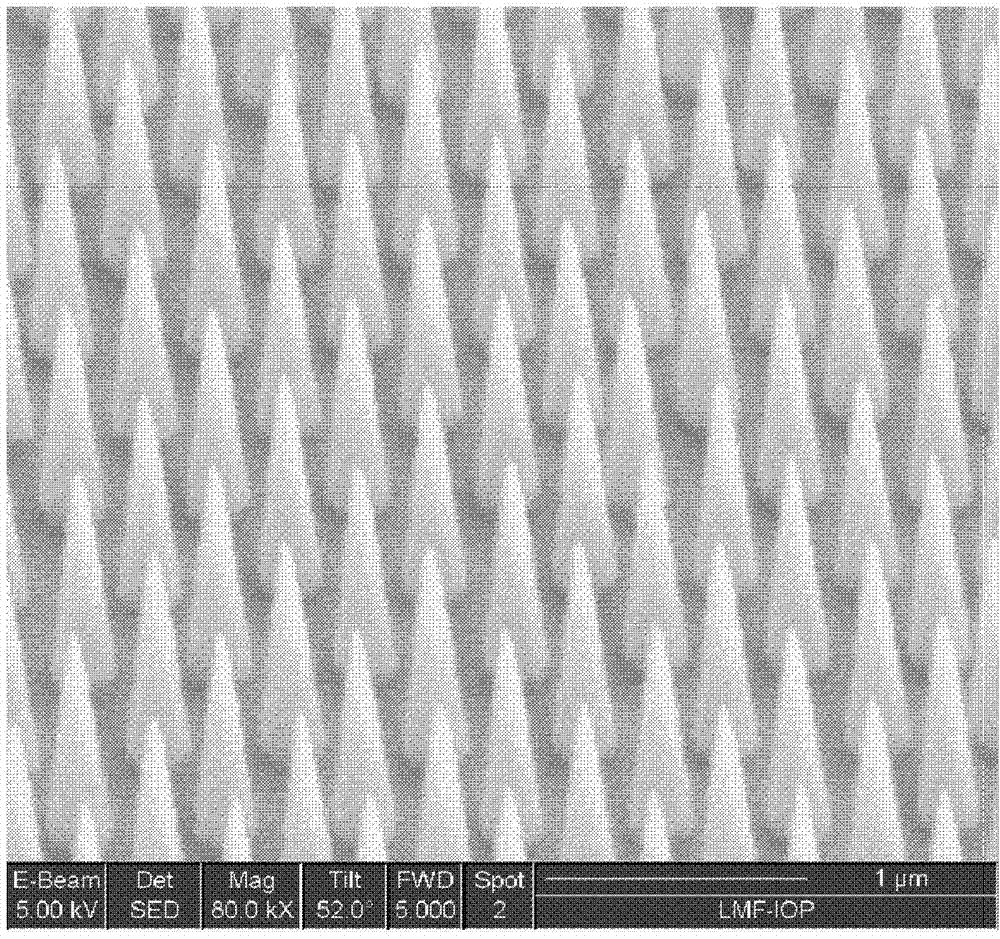

[0042] Embodiment 3: In this embodiment, nano-imprinting, metal coating, stripping and etching techniques are used to prepare a pyramidal structure with a high aspect ratio on the GaP surface with a silicon nitride sacrificial layer grown on the surface, specifically including the following steps:

[0043] Step 1: grow a silicon nitride film with a thickness of 200nm on the surface of the GaP sample by plasma enhanced chemical vapor deposition (PECVD) as a sacrificial mask for etching;

[0044] Step 2: Spin-coat polymethyl methacrylate PMMA photoresist on the surface of the sample, and bake the sample on a hot plate at 180°C for 1 minute after spin-coating;

[0045] Step 3: Prepare a photoresist pattern with a circular hole array on the photoresist using a nanoimprinting device;

[0046] Step 4: put the sample into the electron beam evaporation equipment, and evaporate a layer of gold film with a thickness of 100nm;

[0047] Step 5: put the vapor-deposited sample into an aceton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com