Preparation method of special soybean protein isolate for frozen meat product and application thereof

A technology of soybean protein isolate and soybean protein, which is applied in the fields of preparation of soybean protein products, modification of soybean protein, and modification of plant protein, can solve the problem of insignificant functional changes, independent research on soybean protein functionality, and functional To avoid damage and other problems, to achieve the effect of smooth and delicate section tissue, improved water and oil retention function, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0072] Experimental example 1: Preparation of special soybean protein for frozen meat products

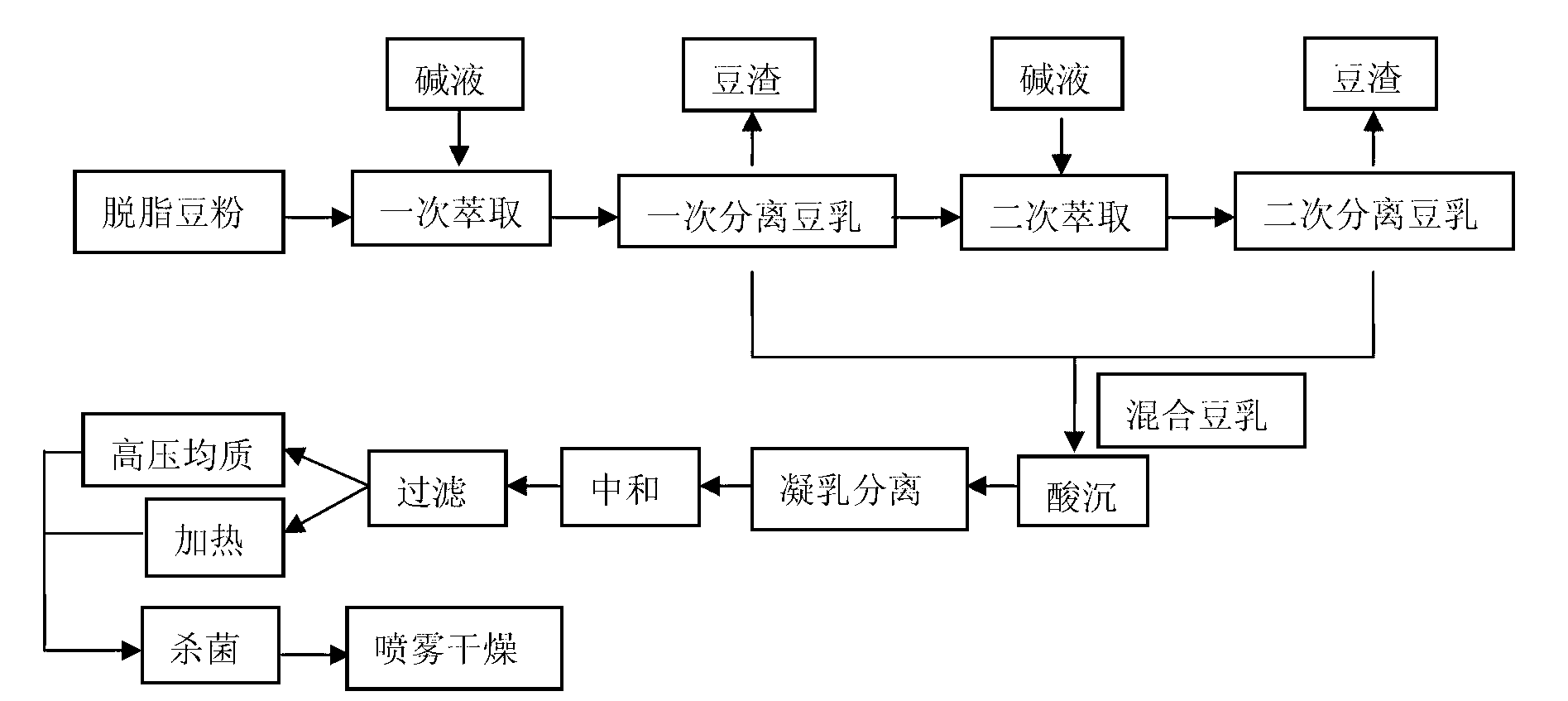

[0073] Flowchart such as figure 1 As shown, the specific steps are as follows:

[0074] A. The low-temperature defatted soybean meal is pulverized and passed through a 80-mesh sieve;

[0075] B. Alkaline extraction: add 0.3mol / L NaOH lye with a pH value of 9 to the low-temperature soybean meal powder at a solid-to-liquid ratio of 1:12 (g:ml), at a temperature of 30°C and a stirring speed of 60r / min. The stirring time is 30 minutes, the low-temperature soybean meal powder is extracted twice with NaOH lye, separated twice, and the extracts are combined to obtain mixed soybean milk;

[0076] C. Acid precipitation: use hydrochloric acid with a concentration of 25% (w / w) to adjust the pH value of the mixed soybean milk to 4.5, stir at a speed of 30r / min, and stir for 10min, centrifuge, remove the supernatant, and obtain centrifuged curd;

[0077] D. Neutralization: Stir to disintegra...

Embodiment 2

[0079] Embodiment 2 Establishment and optimization of the inventive method

[0080] 1 Materials and methods

[0081] 1.1 Main reagents and instruments

[0082] Soybean Protein Isolate Hagaoke Soybean Food Co., Ltd.

[0083] Low-temperature soybean meal Harbin Gaoke Soybean Food Co., Ltd.

[0084] β-Mercaptoethanol Amresco

[0085] Tris Sigma Corporation

[0086] Ellman Reagent Sigma

[0087] 5,5'-Dithiodinitrobenzoate (DTNB) Sigma

[0088] 1-Anilino-8-naphthalenesulfonic acid (ANS) Sigma

[0089] Glycine Sigma

[0090] Other reagents domestic

[0091] AH-100D High Pressure Homogenizer ATS Industrial Systems Co., Ltd.

[0092] HH-S Electric Heating Constant Temperature Water Bath Beijing Yongguangming Medical Instrument Factory

[0093] PHS-3C pH Meter Shanghai Leici Instrument Factory

[0094] DHG-9240A Electric Blast Drying Oven Shanghai Yiheng Scientific Instrument Co., Ltd.

[0095] LD4-2A Low Speed Centrifuge Beijing Medical Centrifuge Factory

[0096] TU-19...

Embodiment 3

[0147] Application Research of Example 3 Soybean Protein Isolate Special for Frozen Meat Products

[0148] Specifically follow the steps below:

[0149] (1) Based on the isolated soybean protein prepared in Experimental Example 1, it was used in the frozen pork ball system to replace a part of lean meat;

[0150] (2) Investigate the relationship between lean meat, fat, corn starch, salt and soybean protein isolate coexistence system's water and oil retention through single-factor experiments, and determine the addition ranges of the content of each coexistent: the ratio of lean to fat is 9:1- 8:2 raw meat 72.5%-83.5%, of which soybean protein isolate replaces 10%-20% of lean meat, corn starch content is 15%-25%, and salt content is 1.5%-2.5%.

[0151] (3) Taking the cooking loss as the monitoring index, an orthogonal experiment of four factors and three levels was carried out, and the basic formula of frozen pork balls was optimized as follows: the ratio of lean to fat was 9:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com