Method for synthesizing polycarboxylic acid plastic-retaining agent at low temperature

A technology of polycarboxylate and plastic-preserving agent, which is applied in the field of concrete additives, can solve the problems such as polycarboxylate plastic-preserving agent that have not been found, and achieve the effects of improving compressive strength, high water-reducing performance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Low-temperature preparation of plastic retaining agent of the present invention (environment temperature is -10°C)

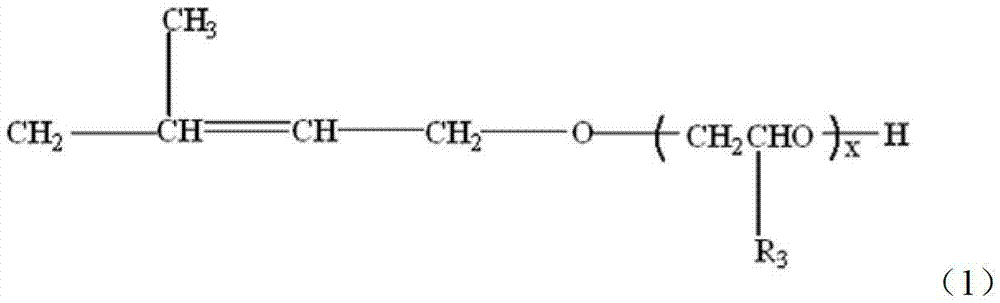

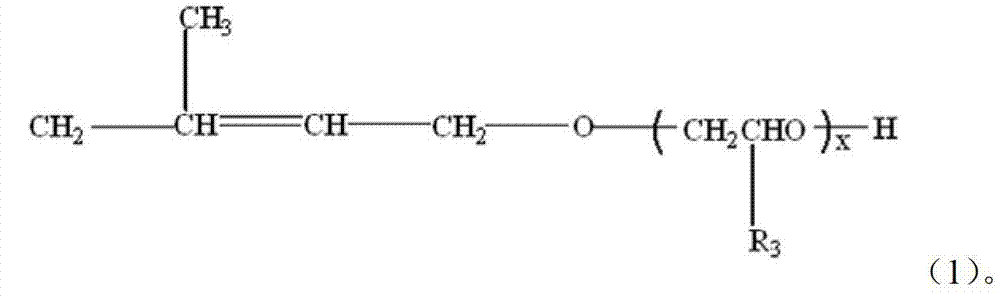

[0028] (a) Prenyl polyether (x=52, R in general formula (1) 3 H) Stir and dissolve together with an aqueous solution of ethylene glycol with a mass concentration of 20% to prepare 300 g of a solution with a mass concentration of 65%;

[0029] (b) Add 4.2g of Diaobai powder to the solution obtained in step (a), stir evenly and configure it as a base material;

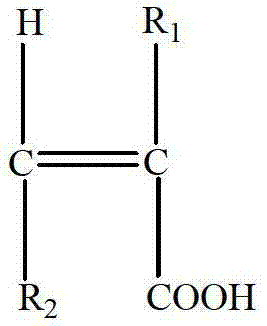

[0030] (c) Add water to methacrylic acid to form an aqueous solution B95g with a mass concentration of 20%;

[0031] (d) Add 3.5g of hydrogen peroxide (30%), 0.8g of initiator ammonium persulfate and water to form a 40g aqueous solution, then add 3g of isopropanol, 0.1g of vinyl acetate, and 0.9g of mercaptoacetic acid, and stir evenly to form a solution A44g;

[0032] (e) Add solution A and solution B dropwise to the bottom material at the same time at ambient temperature. The dropping time of s...

Embodiment 2

[0034] Normal temperature preparation of plastic retaining agent of the present invention (ambient temperature 35°C)

[0035] (a) Prenyl polyether (x=40, R in general formula (1) 3 for -CH 3 ) was stirred and dissolved with water to prepare 300g of a solution with a mass concentration of 65%;

[0036] (b) Add 1.5g of vitamin C to the solution obtained in step (a), stir evenly and configure it as a base material;

[0037] (c) Add acrylic acid and water to form 75g of aqueous solution B with a mass concentration of 18%;

[0038] (d) Add 2.8g of hydrogen peroxide (30%), 1.6g of initiator potassium persulfate and water to make 40g of aqueous solution, then add 1.6g of isopropanol, 0.6g of sodium methacrylate, and 0.8g of mercaptopropionic acid, and stir well , configured into a solution A43g;

[0039] (e) Add solution A and solution B dropwise to the bottom material at the same time at ambient temperature. The dropping time of solution A is controlled at 3.5 hours, and the dro...

Embodiment 3

[0041] Low-temperature preparation of plastic retaining agent of the present invention (environment temperature is -10°C)

[0042] (a) Prenyl polyether (x=25, R in general formula (1) 3 for -CH 3 ) and an aqueous solution of ethylene glycol with a mass concentration of 10% were stirred and dissolved to prepare 300 g of a solution with a mass concentration of 65%;

[0043] (b) Add 2.5g of Diaobai powder to the solution obtained in step (a), stir evenly and prepare 302.5g of base material;

[0044] (c) Add water to maleic acid to prepare 95g of aqueous solution B with a mass concentration of 70%;

[0045] (d) Add 3.8g of hydrogen peroxide (30%), 0.8g of initiator potassium persulfate and water to make 40g of aqueous solution, then add 1g of isopropanol, 0.3g of chain transfer agent vinyl acetate, and 0.5g of mercaptoacetic acid in sequence, and stir evenly , configured into solution A41.8g;

[0046] (e) Add solution A and solution B dropwise to the bottom material at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com