Magnesium-alloy chemical nickel plating solution and nickel plating process thereof

A technology of electroless nickel and magnesium alloy plating, which is applied in the direction of liquid chemical plating, metal material coating technology, coating, etc., can solve the problems of localized corrosion, large limitations, and fast deposition speed, etc., to reduce corrosion and improve Stability and the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] According to the composition of the alkaline electroless nickel plating solution in Table 2, each component was weighed, each component was dissolved in deionized water, and the pH was adjusted to 10.5 with sodium hydroxide, and then supplemented to 100% with deionized water;

[0044] According to the composition of the neutral electroless nickel plating solution in Table 2, dissolve each component in deionized water, adjust the pH to 6.0 with ammonia water, and then make up to 100% with deionized water.

[0045] Get magnesium alloy sample, carry out nickel plating treatment, comprise the following steps:

[0046] 1) Ultrasonic degreasing: the treatment temperature is 50-60°C, and the time is 3-6 minutes;

[0047] 2) Pickling: Phosphoric acid 5-10g / L, citric acid 10-15g / L, urotropine 0.1-0.5g / L, the balance is water; the temperature is 20-30°C, and the time is 1-2min;

[0048] 3) Activation: potassium pyrophosphate 10-15g / L, sodium fluoride 3-5g / L, sodium nitrate 3-5g / ...

Embodiment 2

[0057] The preparation of alkaline electroless nickel solution and neutral electroless nickel solution is the same as in Example 1.

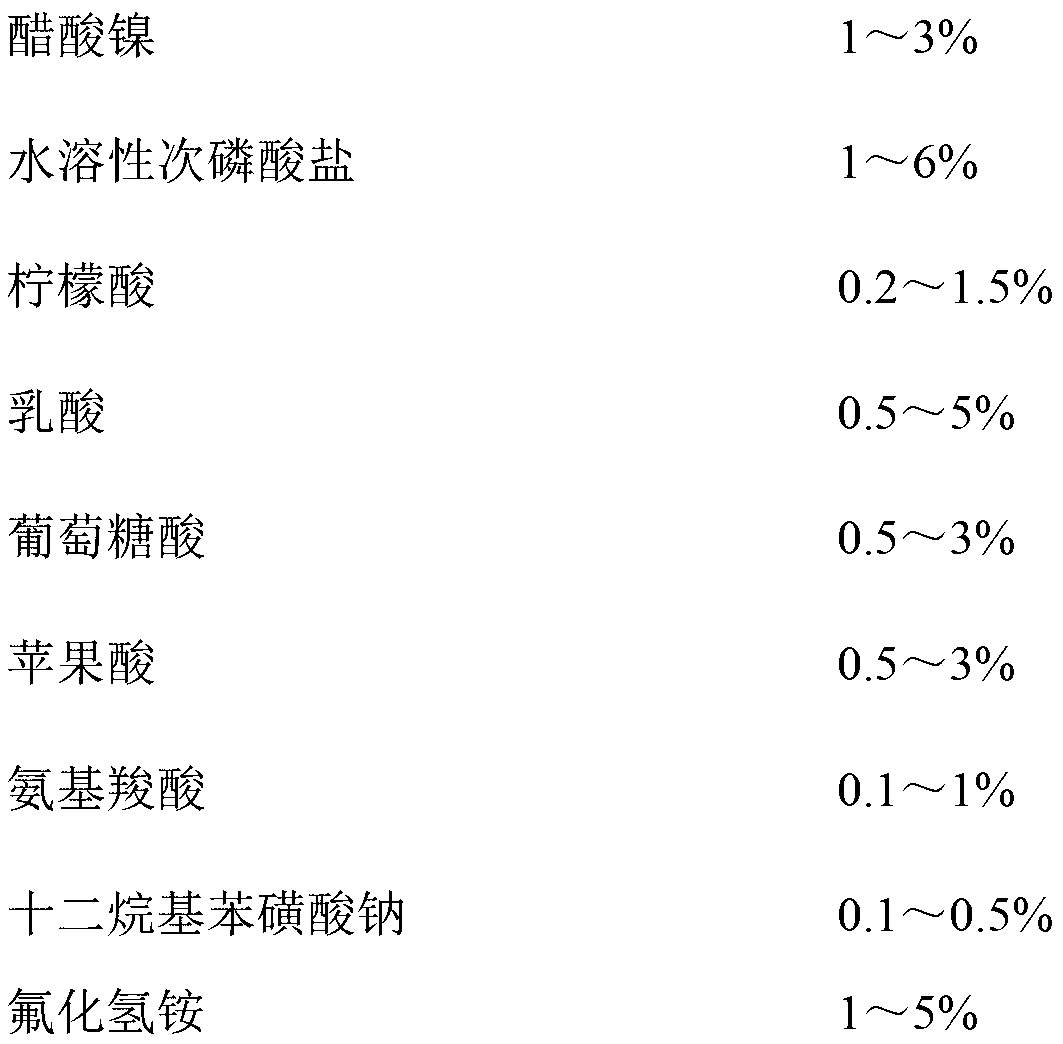

[0058] The composition of alkaline film remover 1# is shown in Table 3.

[0059] Get magnesium alloy sample, carry out nickel plating treatment, comprise the following steps:

[0060] 1) Ultrasonic degreasing: the treatment temperature is 50-60°C, and the time is 3-6 minutes;

[0061] 2) Pickling: Phosphoric acid 5-10g / L, citric acid 10-15g / L, urotropine 0.1-0.5g / L, the balance is water; the temperature is 20-30°C, and the time is 1-2min;

[0062] 3) Ultrasonic alkaline film removal: the treatment temperature is 55-65°C, the time is 0.5-3min, and the ultrasonic frequency is 20-40KHz;

[0063] 4) Activation: potassium pyrophosphate 10-15g / L, sodium fluoride 3-5g / L, sodium nitrate 3-5g / L, sodium gluconate 20-30g / L, organic phosphonate 50-80g / L , the balance is water; the temperature is 50-60°C, and the time is 0.5-1min;

[0064] 5) Base electr...

Embodiment 3~8

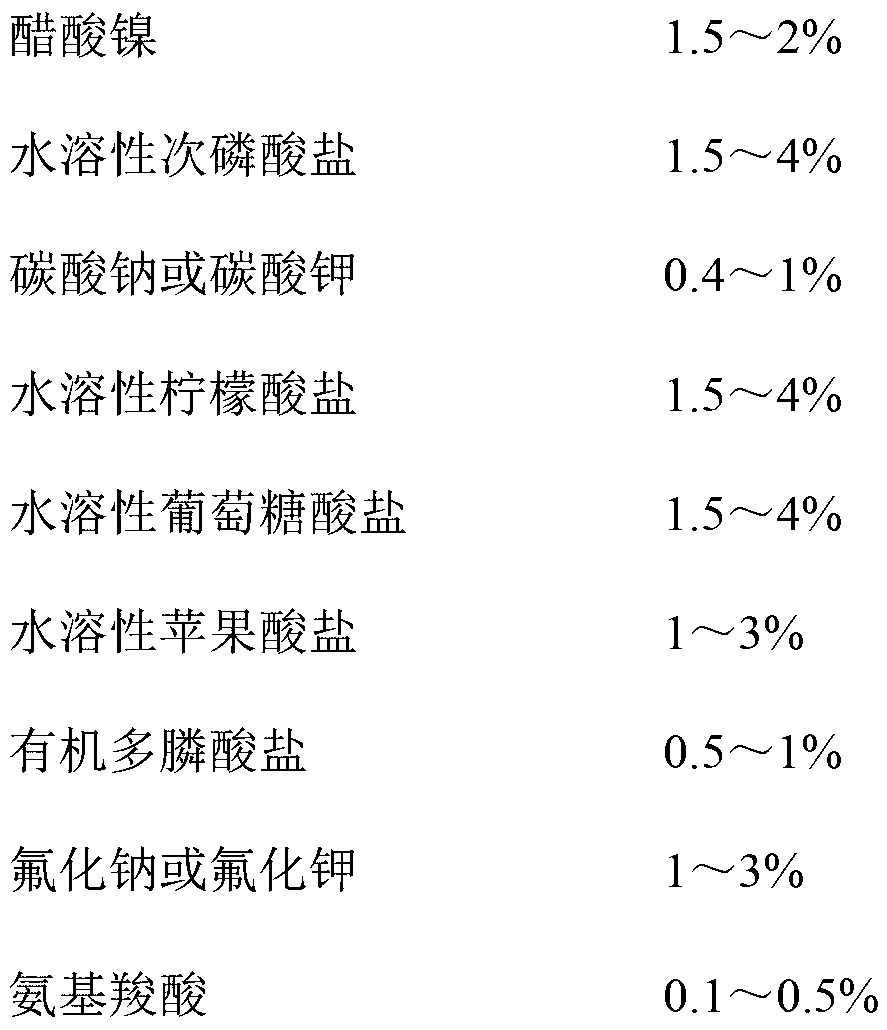

[0071] The process parameter of embodiment 3~8 is similar to embodiment 2. The composition of the electroless nickel plating solution used in each embodiment is shown in Table 2, the composition of the alkaline film remover is shown in Table 3, and the process parameters and nickel plating effect are shown in Table 4.

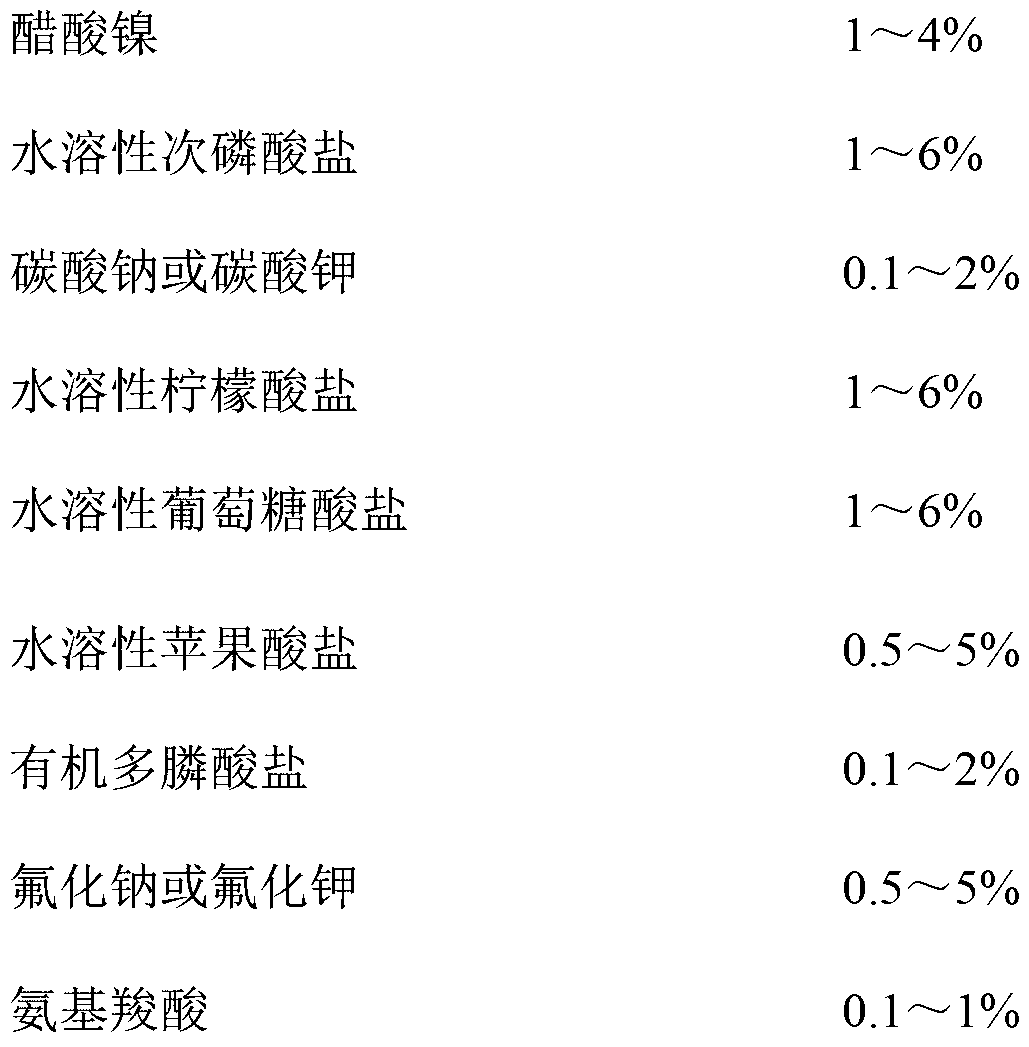

[0072] The composition of electroless nickel plating solution in each embodiment of table 2

[0073]

[0074] Note:

[0075] 1, alkaline electroless nickel plating solution: used hypophosphite is sodium hypophosphite among the embodiment 1~4, is potassium hypophosphite among the embodiment 5~8; Used water-soluble citrate among the embodiment 1~5 is citric acid Sodium, potassium citrate among the embodiments 6~8; Water-soluble gluconate used in the embodiments 1~4 is sodium gluconate, potassium gluconate among the embodiments 5~8; Malic acid used in the embodiments 1~5 The salt is sodium malate, which is potassium malate in Examples 6 to 8; the organic poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com