Method for preparing surface protecting coating layer of light weight alloy

A light alloy and protective coating technology, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problem of poor corrosion resistance, wear resistance and oxidation resistance, and affecting service life, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

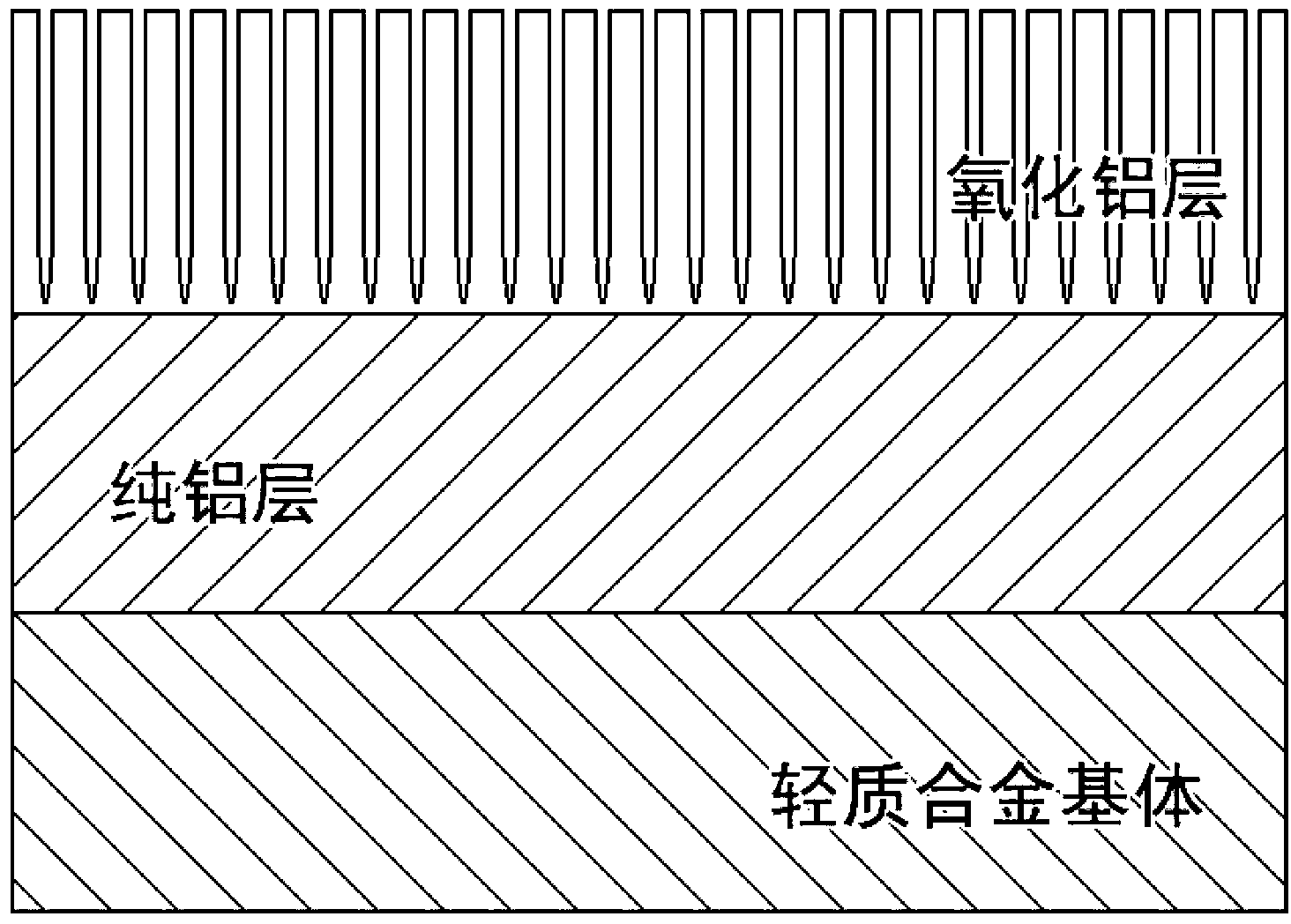

[0052] In this embodiment, the grade of the light alloy is: magnesium alloy AZ31. First, a pure aluminum coating is prepared on the surface of the light alloy as the bottom layer of the protective coating; then, the surface of the pure aluminum coating is polished and anodized, and an aluminum oxide film is prepared on the surface of the pure aluminum coating as a protective coating the surface layer;

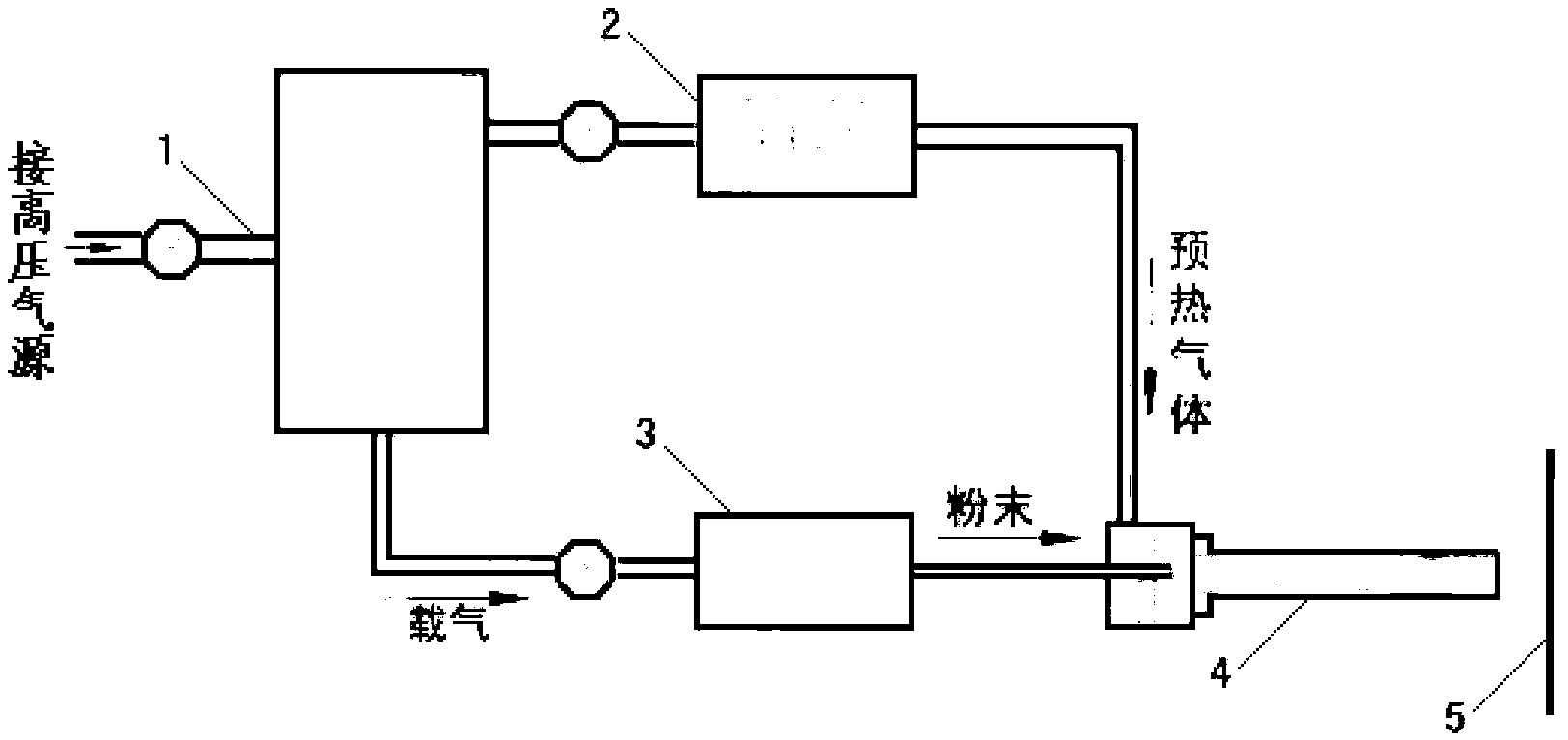

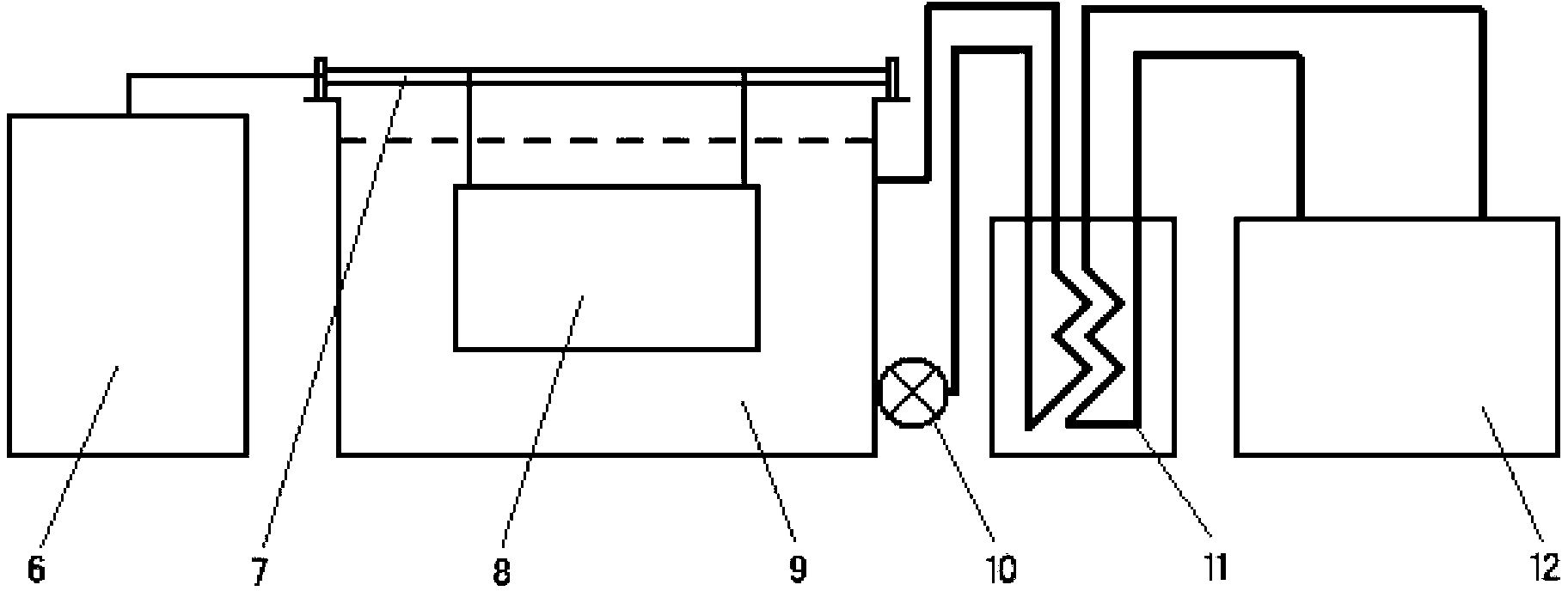

[0053] In this embodiment, the pure Al powder is directly sprayed on the surface of the light alloy by using a high-speed airflow, and by controlling the spraying parameters: the spraying distance is 30mm, the gas pressure is 3.0MPa, the gas temperature is 500°C, the air flow rate is 30g / s, and the powder particle size is 30μm, aluminum powder purity ≥ 99.8wt%, the compressed gas of the high-pressure gas source is helium. The pure aluminum powder is deposited on the surface of the light alloy, and a uniformly distributed pure aluminum coating is obtained on the surface of the ...

Embodiment 2

[0058] In this embodiment, the grade of the light alloy is: aluminum alloy 6063. First, a pure aluminum coating is prepared on the surface of the light alloy as the bottom layer of the protective coating; then, the surface of the pure aluminum coating is polished and anodized, and an aluminum oxide film is prepared on the surface of the pure aluminum coating as a protective coating the surface layer;

[0059] In this example, the pure Al powder is directly sprayed on the surface of the light alloy by using a high-speed airflow, and by controlling the spraying parameters: the spray distance is 5mm, the gas pressure is 1.0MPa, the gas temperature is 300°C, the air flow rate is 10g / s, and the average particle size of the powder is 5μm, the purity of aluminum powder is ≥99.8wt%, and the compressed gas of the high-pressure gas source is nitrogen. The pure aluminum powder is deposited on the surface of the light alloy, and a uniformly distributed pure aluminum coating is obtained o...

Embodiment 3

[0064] In this embodiment, the grade of the light alloy is: titanium alloy Ti751. First, a pure aluminum coating is prepared on the surface of the light alloy as the bottom layer of the protective coating; then, the surface of the pure aluminum coating is polished and anodized, and an aluminum oxide film is prepared on the surface of the pure aluminum coating as a protective coating the surface layer;

[0065] In this example, the pure Al powder is directly sprayed on the surface of the light alloy by using a high-speed airflow. By controlling the spraying parameters: the spraying distance is 20mm, the gas pressure is 2.0MPa, the gas temperature is 400°C, the air flow rate is 20g / s, and the average particle size of the powder is 20μm, aluminum powder purity ≥ 99.8wt%, the compressed gas of the high-pressure gas source is air. The pure aluminum powder is deposited on the surface of the light alloy, and a uniformly distributed pure aluminum coating is obtained on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com