Preparation method of tungsten copper oxide composite powder through hydro-thermal synthesis

A technology of tungsten copper oxide and composite powder is applied in the field of powder metallurgy, which can solve the problems of complicated preparation method and low uniformity, and achieve the effects of wide applicability, control of reaction and crystal growth, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

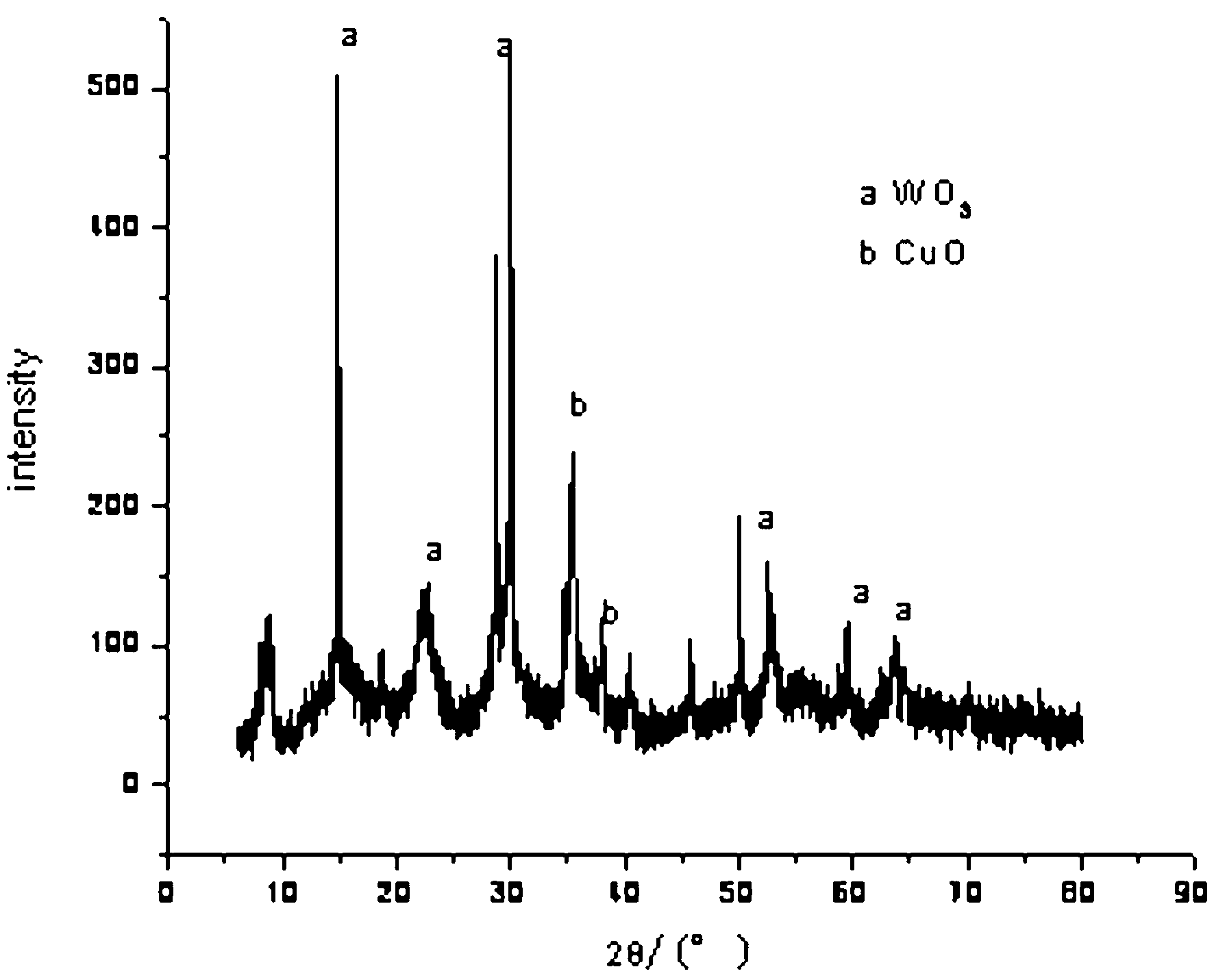

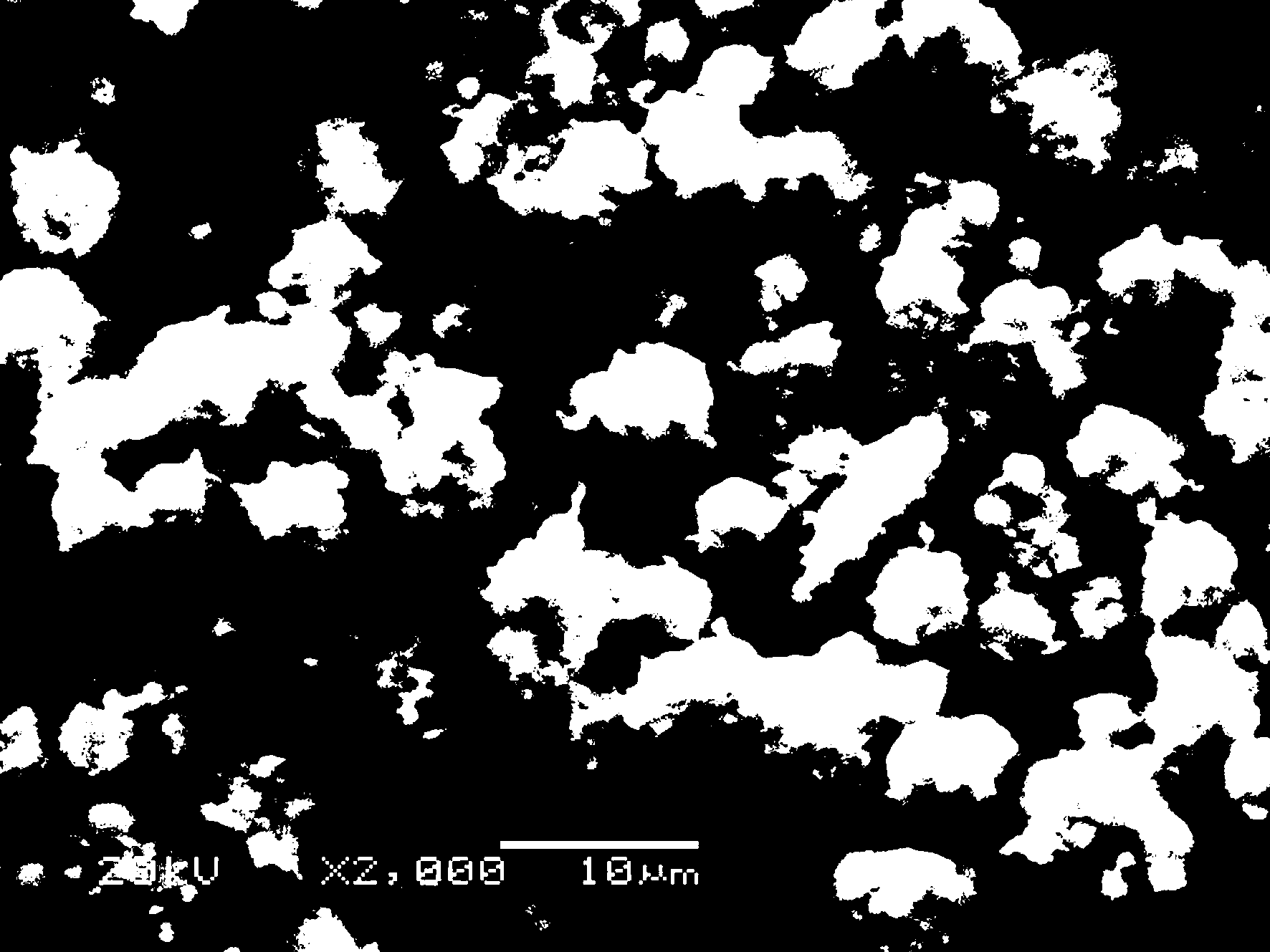

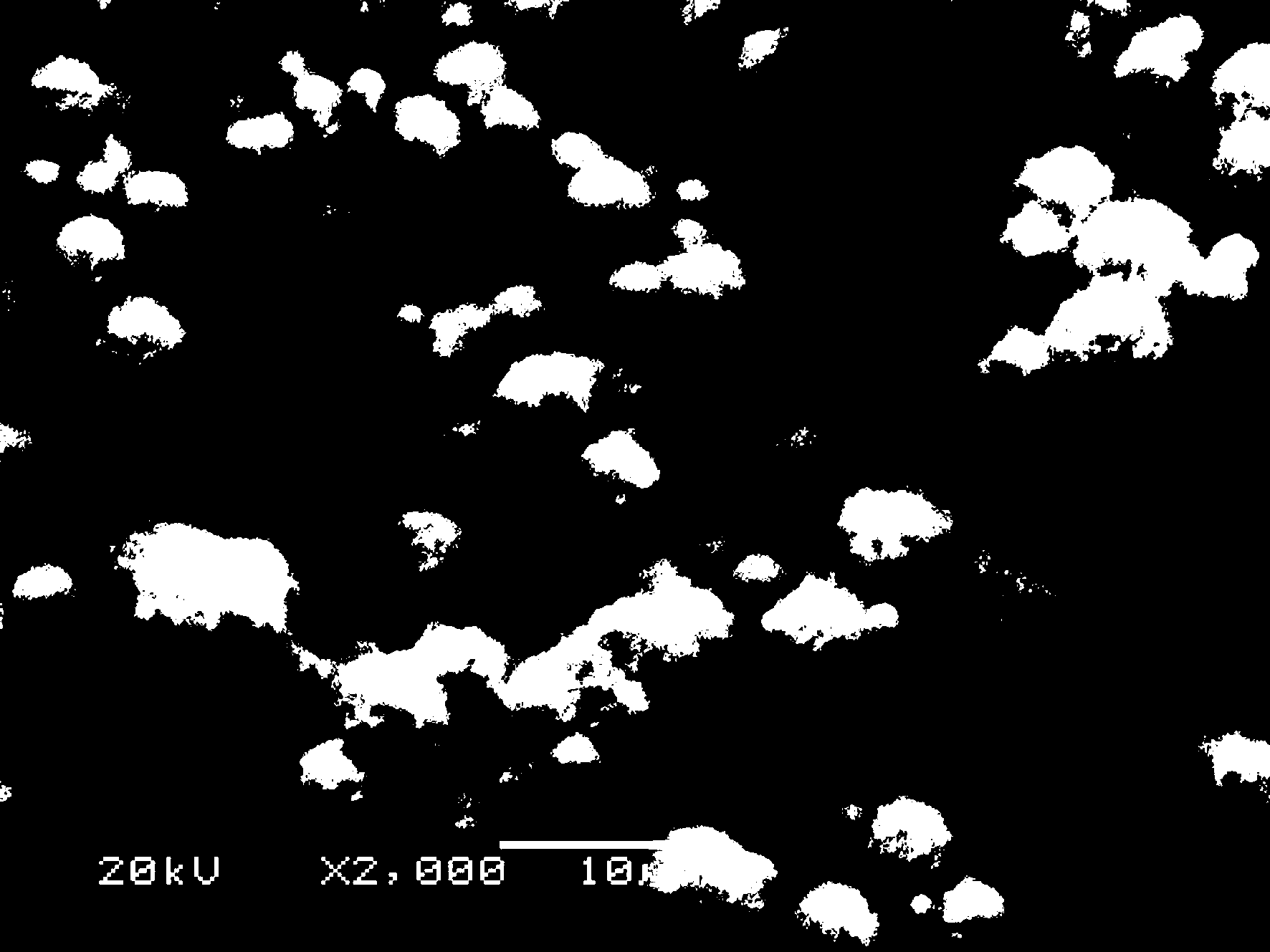

Image

Examples

preparation example Construction

[0021] A preparation method for hydrothermally synthesizing tungsten-copper oxide composite powder, comprising the following steps:

[0022] Step 1: Take sodium tungstate and copper nitrate as raw materials according to the mass ratio of 1.42-0.20, and then prepare solutions respectively, wherein the concentration of copper nitrate is 2.0-2.2mol / L, and the concentration of sodium tungstate is 1.29-0.18mol / L. Then add the prepared sodium tungstate solution to the copper nitrate solution, mix thoroughly to obtain a mixed solution, and then use NaOH solution to adjust the pH value of the mixed solution to 5~6, so that the mixed solution appears sol;

[0023] Step 2: Put the sol-containing mixed solution obtained in Step 1 into a high-pressure reactor, react for 20-25 hours at a pressure of 6-20 MPa and a temperature of 160-180°C, and then cool naturally;

[0024] Step 3: After filtering out the reaction product obtained in Step 2, wash it with absolute ethanol and deionized water...

Embodiment 1

[0027] A preparation method for hydrothermally synthesizing tungsten-copper oxide composite powder, comprising the following steps:

[0028] Step 1: Take sodium tungstate and copper nitrate as raw materials according to the mass ratio of 1.42, and then prepare solutions respectively, wherein the concentration of copper nitrate is 2.0mol / L, and the concentration of sodium tungstate is 1.29mol / L, and then the prepared tungstic acid Add the sodium concentration to the copper nitrate solution, stir for 10 minutes, and ultrasonicate for 10 minutes at 25°C to make it fully mixed to prepare a mixed solution, and then use 2.5mol / L NaOH solution to adjust the pH value of the solution to 5, so that the mixed solution appears Sol;

[0029] Step 2: Put the sol-containing mixed solution obtained in Step 1 into a high-pressure reactor, react for 20 hours at a pressure of 10 MPa and a temperature of 160°C, and then cool naturally;

[0030] Step 3: After filtering out the reaction product ob...

Embodiment 2

[0032] A preparation method for hydrothermally synthesizing tungsten-copper oxide composite powder, comprising the following steps:

[0033] Step 1: Take sodium tungstate and copper nitrate as raw materials according to the mass ratio of 0.2, and then prepare solutions respectively, wherein the concentration of copper nitrate is 2.1mol / L, and the concentration of sodium tungstate is 0.18mol / L, and then the prepared tungstic acid Add the sodium concentration to the copper nitrate solution, stir for 12 minutes, and ultrasonicate for 10 minutes at 25°C to make it fully mixed to prepare a mixed solution, and then adjust the pH value of the solution to 5.5 with 2.5mol / L NaOH solution to make the mixed solution appear Sol;

[0034] Step 2: Put the sol-containing mixed solution obtained in Step 1 into a high-pressure reactor, react for 22 hours at a pressure of 12 MPa and a temperature of 165°C, and then cool naturally;

[0035] Step 3: After filtering out the reaction product obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com