Detection method of lithium hexafluorophosphate solution

A technology of lithium hexafluorophosphate and detection method, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of long detection time, poor operability and practicability, and high detection cost, achieve good operability and practicability, and reduce operation. cost, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

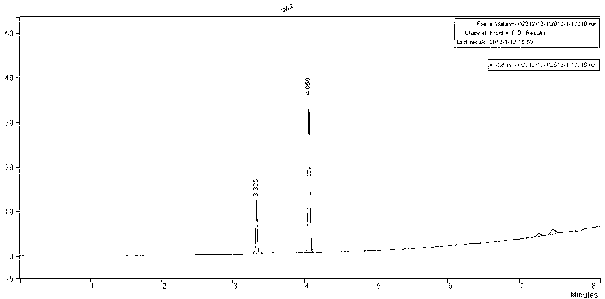

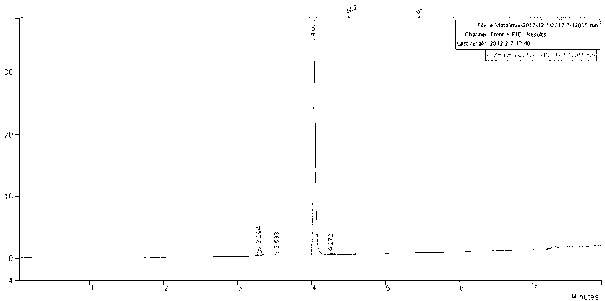

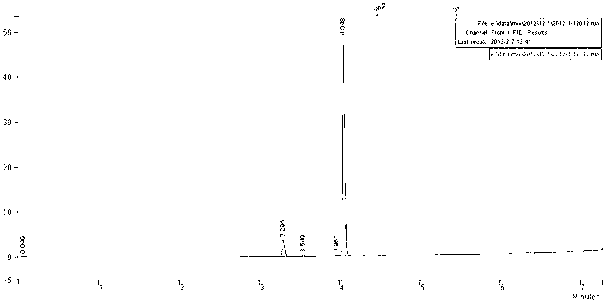

[0047] Example 1 LiPF 6 POF in solution 3 Content detection

[0048] 1) Preparation of LiPF 6 the solution

[0049] Sample A: LiPF provided directly by a supplier 6 solution, wherein the organic solvent EMC is 70wt%, LiPF 6 is 30wt%.

[0050] Sample B and sample C respectively use solid LiPF 6 formulated.

[0051] Preparation method:

[0052] In an argon-filled glove box (moisture 6 , and control the temperature of the solution during the addition process not to exceed 30 ° C, after stirring evenly, make LiPF 6 Solution (70wt% EMC, 30wt% LiPF 6 ) set aside for later use.

[0053] 2) POF 3 Assay

[0054] Clean the sealed container in advance and bake it at 120 degrees for 24 hours. When it is needed, install the sample bottle with the 2P connector, connect the vacuum tube of the 2S connector to the 2P connector to vacuum for 20 seconds, close the vacuum valve; then open the nitrogen valve to the sample. Fill the bottle with nitrogen, and repeat the above ...

Embodiment 2

[0066] Example 2 Lithium battery performance test

[0067] 1, using three kinds of LiPF of embodiment 1 6 Solution samples A, B, and C were prepared into LiPF 6 Electrolyte

[0068] In an argon-filled glove box (moisture 6 , The organic solvent is the electrolytic solution of EC:DMC:EMC =1:1:1 (wt%) respectively.

[0069] Wherein respectively adopt the LiPF of embodiment 1 6 The solution samples A, B, and C are prepared, and the organic solvent is prepared with a high-purity solvent (purity is better than 99.99%, and the water content is lower than 10PPM). During the preparation process, the temperature of the solution during the addition process was controlled not to exceed 30°C, and after stirring evenly, the lithium battery electrolytes A1, B1, and C1 were respectively obtained.

[0070] 、 Preparation of lithium battery

[0071] According to the battery manufacturing process, the above-mentioned lithium battery electrolytes A1, B1, and C1 are used to make 454046A750...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com