Preparation method for polyacrylonitrile immobilized enzyme

A technology of polyacrylonitrile and immobilized enzymes, which is applied to the fields of immobilized on/in organic carriers, biochemical fiber treatment, non-woven fabrics, etc. Recycling and other issues, to achieve the effect of improving the utilization rate of enzymes, high porosity, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

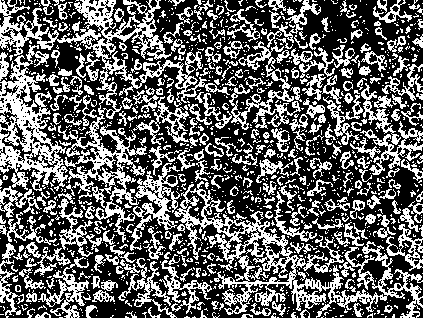

[0020] The preparation method of the polyacrylonitrile nanofiber membrane is as follows: dissolving polyacrylonitrile in N,N-dimethylformamide solvent to form a solution with a weight percentage of 5% to 10%. Then, inject the prepared solution into the electrospinning device, and perform electrospinning under the conditions of a voltage of 12-20 kV, a flow rate of the spinneret solution of 0.8-1.5 ml / hour, and a receiving distance of 10-20 cm. A fiber membrane with a fiber diameter of 100-600 nanometers is obtained. The obtained fiber membrane is placed in a vacuum drying oven and dried under the condition of 30° C. to 50° C. for 5 hours to 12 hours.

[0021] Immerse 1 gram of polyacrylonitrile nanofiber membrane in pure ethanol solution, and pass through hydrogen chloride gas for 10 minutes. The nanofibrous membrane was taken out and fully rinsed with a phosphate buffer solution with a pH of 7.0 to remove residual ethanol on the membrane. Then, immerse the activated nanofib...

Embodiment 2

[0024] Immerse 1 gram of polyacrylonitrile nanofiber membrane in pure ethanol solution, and pass through hydrogen chloride gas for 20 minutes. The nanofibrous membrane was taken out and fully rinsed with a phosphate buffer solution with a pH of 7.0 to remove residual ethanol on the membrane. Then, immerse the activated nanofibrous membrane in a 1.0 mg / ml laccase phosphate buffer solution, seal it and vibrate for 3 hours at 30° C. with a rotation speed of 80 rpm. The membrane was taken out from the solution and washed repeatedly with deionized water for 5 times to obtain the polyacrylonitrile nanofiber membrane immobilized laccase. The nanofibrous membrane immobilized with laccase was immersed in a phosphate buffer solution with a pH of 5.0, and stored at 4°C for use.

Embodiment 3

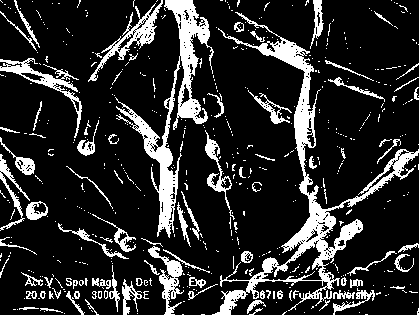

[0026] Immerse 1 gram of polyacrylonitrile nanofiber membrane in pure ethanol solution, and pass through hydrogen chloride gas for 15 minutes. The nanofibrous membrane was taken out and fully rinsed with a phosphate buffer solution with a pH of 7.0 to remove residual ethanol on the membrane. Then, immerse the activated nanofibrous membrane in a horseradish peroxidase phosphate buffer solution with a concentration of 1.0 mg / ml, seal it and vibrate for 1.5 hours at 20° C. at a speed of 60 rpm. The membrane is taken out from the solution, washed repeatedly with deionized water for 3 times, and the immobilized horseradish peroxidase and polyacrylonitrile nanofiber membrane can be obtained. The nanofibrous membrane immobilized with horseradish peroxidase was immersed in a phosphate buffer solution with a pH of 5.0, and stored at 4°C for use.

[0027] From figure 2 From the results of the scanning electron microscope, it can be seen that the polyacrylonitrile nanofiber membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com