High-biological activity composite material for promoting bone regeneration repair and preparation method thereof

A bioactive, composite material technology, applied in the field of highly bioactive composite materials and preparations for promoting bone regeneration and repair, can solve problems such as difficulty in promoting bone defects, and achieve the effects of improving mechanical strength, excellent biological activity, and efficient degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

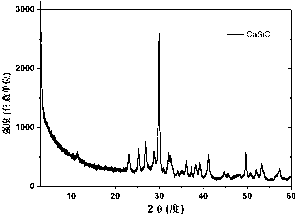

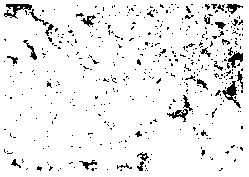

[0045] 1) Will contain 0.24 mol / L CaCl 2 and 0.01 mol / L SrCl 2 200 mL of aqueous solution was added dropwise to 200 mL of magnetically stirred 0.25 mol / L sodium silicate aqueous solution. After the dropwise addition was completed, the reaction sediment was filtered, washed three times with deionized water, and then washed once with ethanol. 80 o C drying, and then placed in a high temperature furnace at 850 o Calcined at C for 2 hours to obtain strontium ion-doped calcium silicate powder, the particle size was analyzed by a particle size detector, and the particle size was between 2 and 26 μm, and the strontium content in the powder was 0.31 μm by atomic absorption spectrometry. %; It can be seen that the powder is calcium silicate (such as figure 1 shown), and its powder is fine particles with certain agglomeration (such as figure 2 shown).

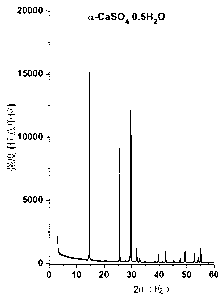

[0046] 2) Prepare 4 L mixed aqueous solution with calcium sulfate dihydrate, sodium chloride and citric acid at the mass volume ...

Embodiment 2

[0049] 1) Will contain 0.27 mol / L Ca(NO 3 ) 2 and 0.01 mol / L MgCl 2 500 mL of the aqueous solution was added dropwise to 500 mL of magnetically stirred 0.28 mol / L sodium silicate aqueous solution. After the dropwise addition was completed, the reaction sediment was filtered, washed three times with deionized water, and then washed once with ethanol, and then at 85 o C drying, and then placed in a high temperature furnace at 1150 o Calcined at C for 2 hours to obtain magnesium ion-doped calcium silicate powder, the particle size was analyzed by a particle size detector, and the particle size was between 6 and 31 μm, and the magnesium content in the powder was 0.30 μm by atomic absorption spectrometry. %.

[0050] 2) Prepare 2 L mixed aqueous solution with calcium sulfate dihydrate, sodium chloride and citric acid at the mass volume concentration of 15%, 15% and 0.10% respectively. o C under continuous mechanical stirring for 4.5 hours, then filtered, washed twice with boi...

Embodiment 3

[0053] 1) Will contain 0.23 mol / L CaCl 2 and 0.02 mol / L Zn(NO 3 ) 2Add 1,000 mL of inorganic salt solution dropwise to 1,000 mL of magnetically stirred 0.25 mol / L sodium silicate aqueous solution. After the dropwise addition, filter the reaction sediment, wash it with deionized water three times, and then wash it once with ethanol. , at 80 o C drying, and then placed in a high temperature furnace at 750 o Calcined at C for 2 hours to obtain zinc ion-doped calcium silicate powder, the particle size was analyzed by a particle size detector, and the particle size was between 9 and 32 μm, and the zinc content in the powder was 1.45 μm by atomic absorption spectroscopic analysis. %.

[0054] 2) Prepare 5 L mixed aqueous solution with calcium sulfate dihydrate, sodium chloride and citric acid according to the mass volume concentration of 15%, 15% and 0.06% respectively. o Continue mechanical stirring at C for 6 hours, then filter, wash with boiling water twice, wash with ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com