Method for preparing graphene quantum dot powder on large scale

A graphene quantum dot and powder technology, applied in graphene, nanotechnology, nanocarbon and other directions, can solve the problems of long preparation period, small preparation amount, high energy consumption, etc. The effect of route innovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

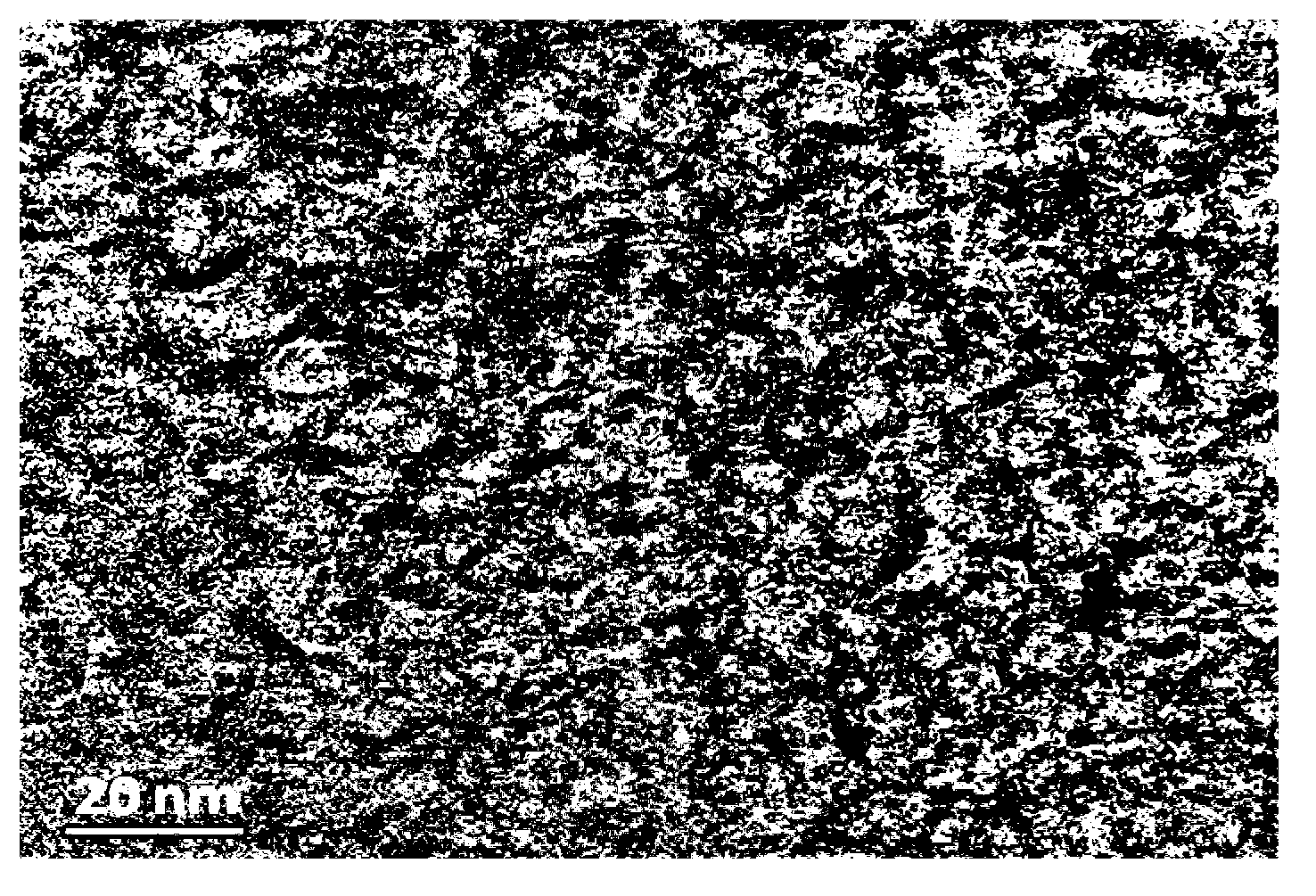

[0045] The first step: take 325 meshes of natural flake graphite and carry out wet grinding: the grinding wet material contains 35wt% graphite, 5wt% dispersant (the dispersant is a mixed dispersant, including sodium carboxymethyl cellulose and sodium polyacrylate, both The mass ratio is 1:1, add ammonia water to adjust the pH value to 12), and the rest is water; grind for 6 hours, add an appropriate amount of water every 1 hour during the grinding process to ensure that the viscosity of the wet material and the percentage of graphite remain unchanged. After grinding, Dry at 60°C for 20h; the average particle size of the prepared graphite nanoparticles is 50nm, and the TEM picture is as follows figure 1 shown;

[0046] The second step: adopt the improved Brodie method to prepare nano-graphite oxide, take 4g of nano-graphite prepared in the first step and add it to 70mL concentrated HNO 3 (67wt%), the oxidant NaClO at 0°C 3 (66g) was slowly added to concentrated HNO 3 , stirr...

Embodiment 2

[0051] The first step: take the natural flake graphite with a particle size of 200 meshes and carry out wet grinding: the grinding wet material contains 30wt% graphite, 5wt% dispersant (the dispersant is a mixed dispersant, including sodium carboxymethylcellulose and sodium polyacrylate, The mass ratio of the two is 1:1, add ammonia water to adjust the pH to 12), and the rest is moisture: water / ethanol mixture; grind for 6 hours, add appropriate amount of moisture every 30 minutes during the grinding process to ensure the viscosity of the wet material and the percentage of graphite The content remains unchanged, and vacuum drying at 80° C. for 18 hours after grinding is completed; 25 g of nano-graphite particles with a particle diameter of 100 nm are prepared.

[0052] The second step: using the improved Staudenmaier method to prepare intercalated nano-graphite oxide: take 25g of finely ground graphite nanoparticles and add them to a mixture of 285mL concentrated nitric acid (c...

Embodiment 3

[0055] The first step: prepare nano-graphite particles, same as Example 2;

[0056]The second step: prepare nano-graphite oxide by the improved Hummers method: get 70ml of 98wt% concentrated sulfuric acid, add 5g nano-graphite particles and 4g NaNO respectively during stirring 3 , control the temperature of the reaction solution at 0-5°C, slowly add 18g KMnO 4 Powder, stir and react for 1h; raise the temperature to 35°C, react for 3h; add 100ml of deionized water, raise the temperature of the reactant to 95°C, and react for 1h; dilute the reaction solution with deionized water and add 20ml of 30wt% H 2 o 2 , stirred for 1 h; filtered and washed with 1M HCl for 3-5 times, then filtered and washed with deionized water until neutral, and the obtained nano graphite oxide was dried at 60 ° C for 20 h to obtain 6.5 g of first-order intercalated nano graphite oxide;

[0057] Step 3: Take 1g of intercalated nano-graphite oxide, lay it flat in a non-closed crucible with a cover (leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com