Preparation method of polycrystal SAPO-53 molecular sieve

A SAPO-53, molecular sieve technology, applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali-exchanged phosphate, etc., can solve the problems of preparation and use limitation, difficult synthesis, difficult synthesis, etc., and achieve low toxicity and strong irritation. and corrosive, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 30 grams of hexamethonium bromide into a round bottom flask, add 120 ml of absolute ethanol and 100 ml of isopropanol, then add 10 grams of sodium bromide and 20 grams of sodium hydroxide, and stir at 60°C for 4 to 6 hours. The reactant was cooled to room temperature, and sodium bromide was precipitated due to its low solubility in the alcoholic solution, and the hexanebiammonium hydroxide generated was dissolved in the alcoholic solution. After filtration, the filtrate was distilled under reduced pressure with a rotary evaporator to obtain hexanediammonium hydroxide with a yield of 91.2% and a purity of 85.6%. The evaporated organic solvent is recovered and reused.

[0032] Add 30ml of water to the beaker, add 7 grams of 65.5wt% pseudo-boehmite, drop 4ml of 85wt% phosphoric acid, after the pseudo-boehmite is completely dissolved, add 2.6 grams of hexanediammonium hydroxide, 30wt% silica sol 4ml, stirred for 1 hour to form a uniform silicoaluminophosphate gel, tr...

Embodiment 2

[0037] Weigh 30 grams of hexamethonium bromide into a round bottom flask, add 150 ml of absolute ethanol and 120 ml of isopropanol, then add 10 grams of sodium bromide and 25 grams of sodium hydroxide, and stir at 75°C for 4 to 6 hours. The reactant was cooled to room temperature, the precipitated sodium bromide was filtered, and the filtrate was distilled under reduced pressure at 20-70°C with a rotary evaporator to obtain hexanediammonium hydroxide with a yield of 89.1% and a purity of 84.8%. The evaporated organic solvent is recovered and reused.

[0038] Add 30ml of water to the beaker, add 8 grams of aluminum isopropoxide and 6 grams of hexanediammonium hydroxide in sequence, add 3ml of 85wt% phosphoric acid dropwise after dissolving, then add 8ml of 30wt% silica sol, and stir for 2 hours to form a uniform silica gel. The aluminum phosphate gel was transferred to a high-pressure reactor with a polytetrafluoroethylene liner, and was statically crystallized at 160°C for 2 d...

Embodiment 3

[0043] The specific steps and synthesis conditions are the same as in Example 1. The organic solvent used to prepare the template is a mixture of 150ml ethanol and 100ml n-propanol, the silicon source used is 2ml tetraethyl orthosilicate (TEOS), and the phosphorus source used is 2.5 grams of hydrogen phosphate Ammonium and 85wt% phosphoric acid 1.5ml, template agent hexane diammonium hydroxide dosage 3 grams, crystallization temperature 170 ° C, crystallization time 3 days.

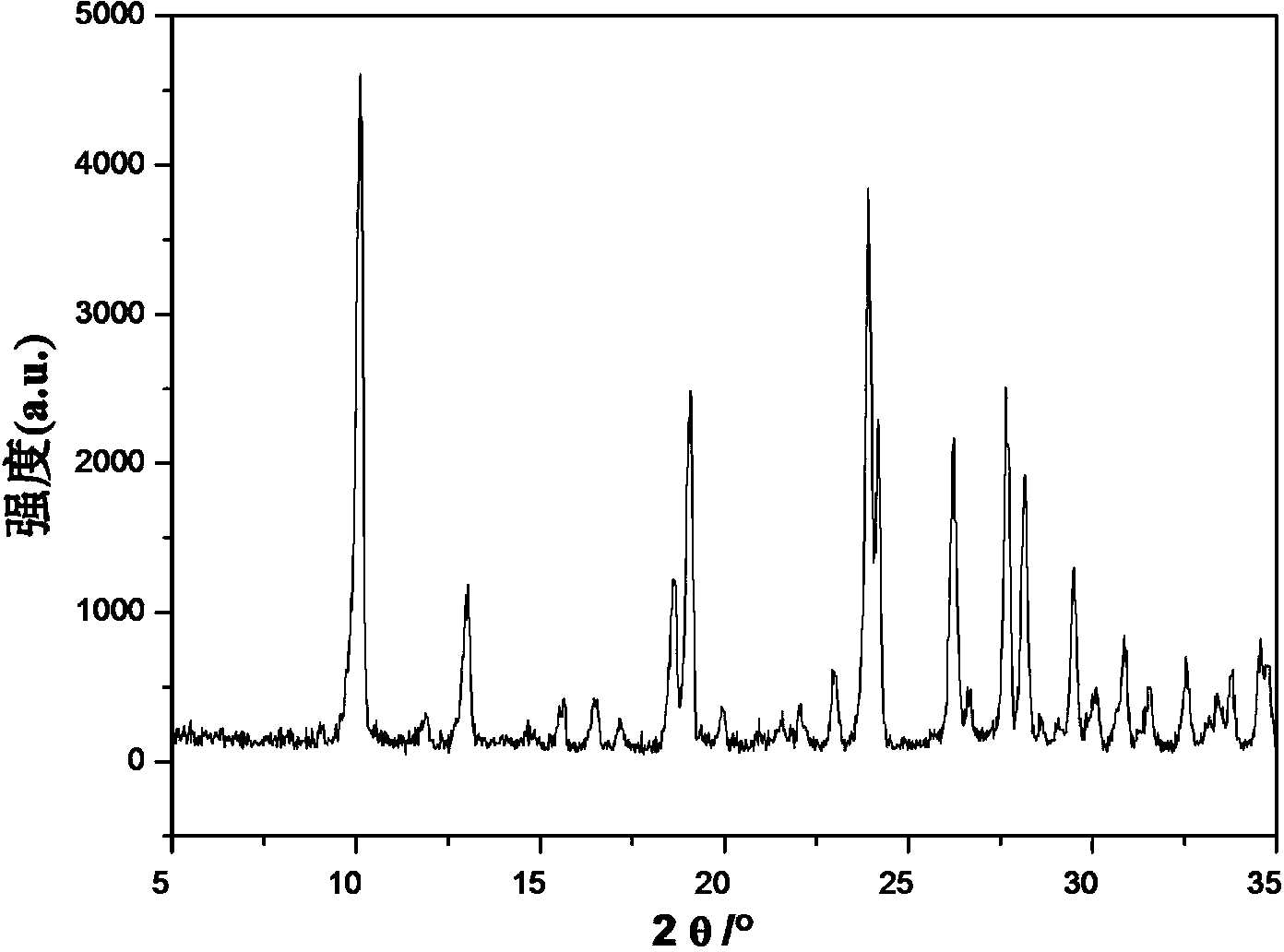

[0044] Figure 5 is the XRD spectrum of the synthesized sample. It can be seen that the molecular sieve has an AEN structure and has a good crystallinity.

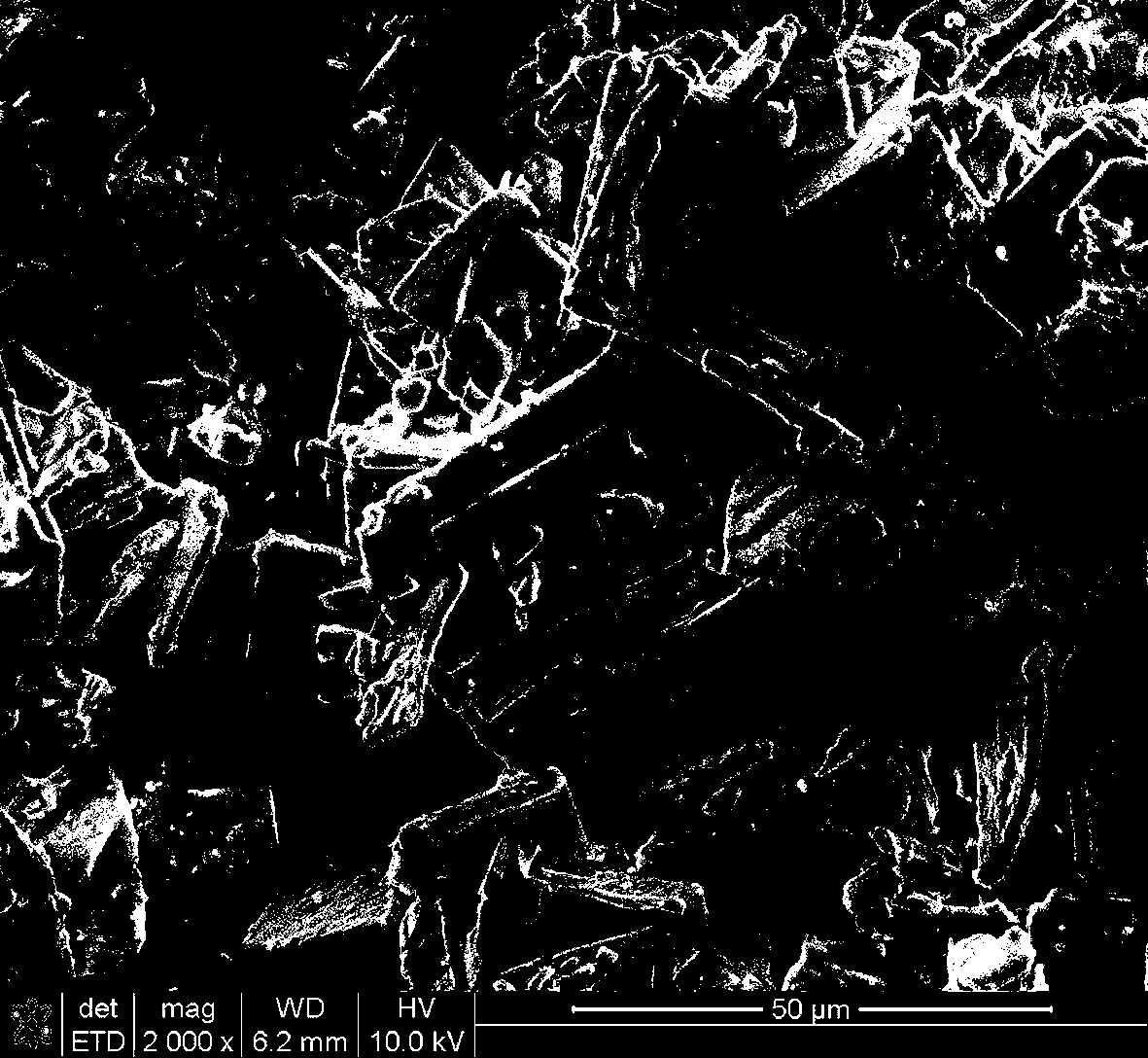

[0045] Image 6 This is the SEM image of the synthesized sample. Due to the low silicon content and relatively low temperature, the sample has a long strip-like stacked crystal appearance. There are glutinous rice-like crystal particles on the outer surface of the strip crystal, and the particle size is about 5-20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com