Catalyst for removing nitrogen oxide in emission exhaust and preparation method thereof

A technology of nitrogen oxides and oxides, applied in the field of catalysts and preparations for removing nitrogen oxides in exhaust gas, can solve problems such as poor sulfur resistance, loss of redox ability, and loss of cerium-based materials, and achieve low price , the source of raw materials is convenient, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

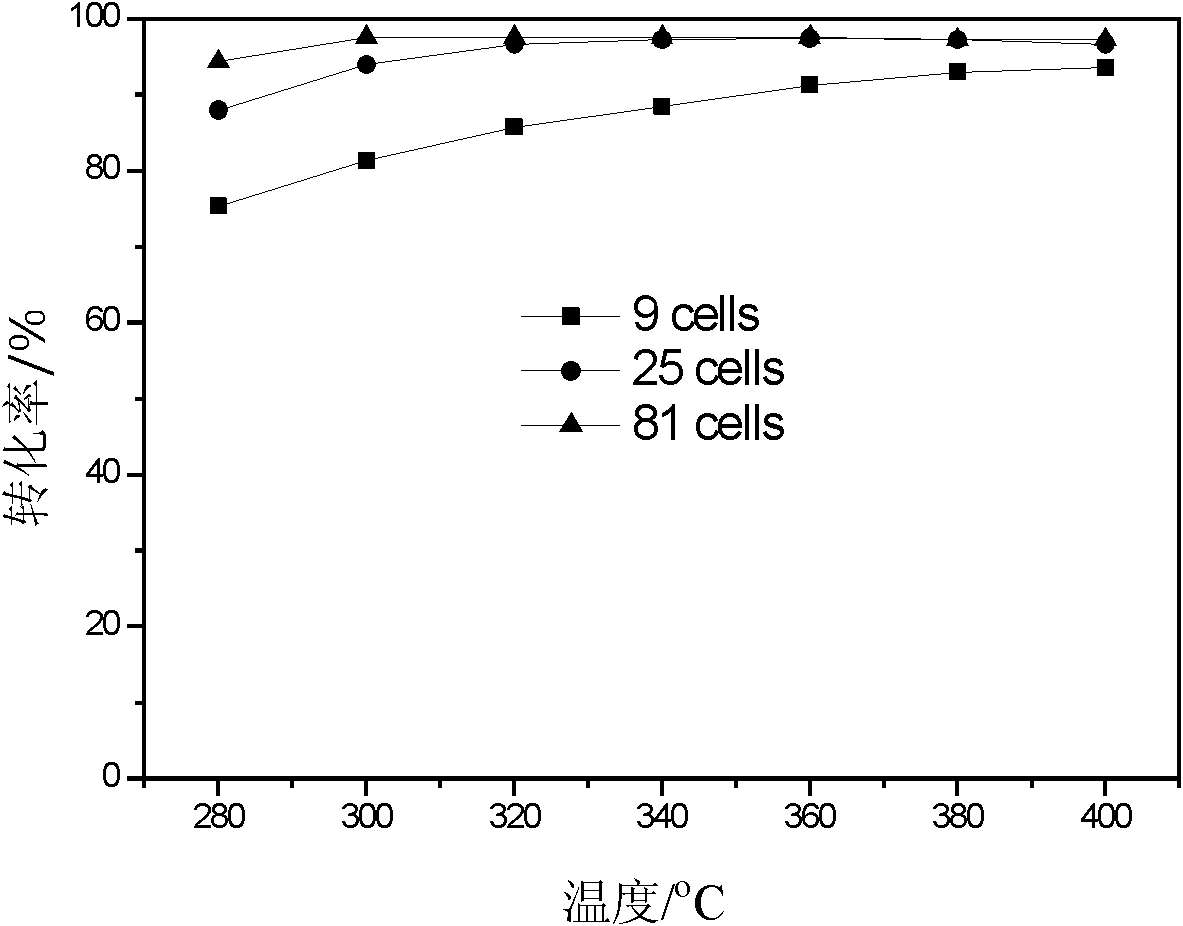

[0040] Commercial metatitanic acid was calcined at 500°C for 4 hours to obtain titanium dioxide. The average particle size was measured by a laser particle size analyzer to be 1.6 μm, and the specific surface area was 70 m by BET analysis. 2 / g. Mix 882g of the above-mentioned titanium dioxide, 56g of cerium-zirconium composite oxide powder with a cerium-zirconium molar ratio of 4:1 prepared by homogeneous precipitation method, and 97.7g of ammonium paratungstate, and then add it into the kneader. Take 50mL of 25% ammonia water and 300mL of deionized water to make a solution, add it into the kneader and start kneading. 54.5 g of kaolin, 23 g of methylcellulose, 32.5 g of glass fiber and 25 g of glycerin were also added during the kneading process. Knead for a period of time until the material is uniform and the water content is appropriate to obtain catalyst sludge. After the catalyst mud is stale for 24 to 48 hours, vacuum mud refining is started. After the drilled mud is ...

Embodiment 2

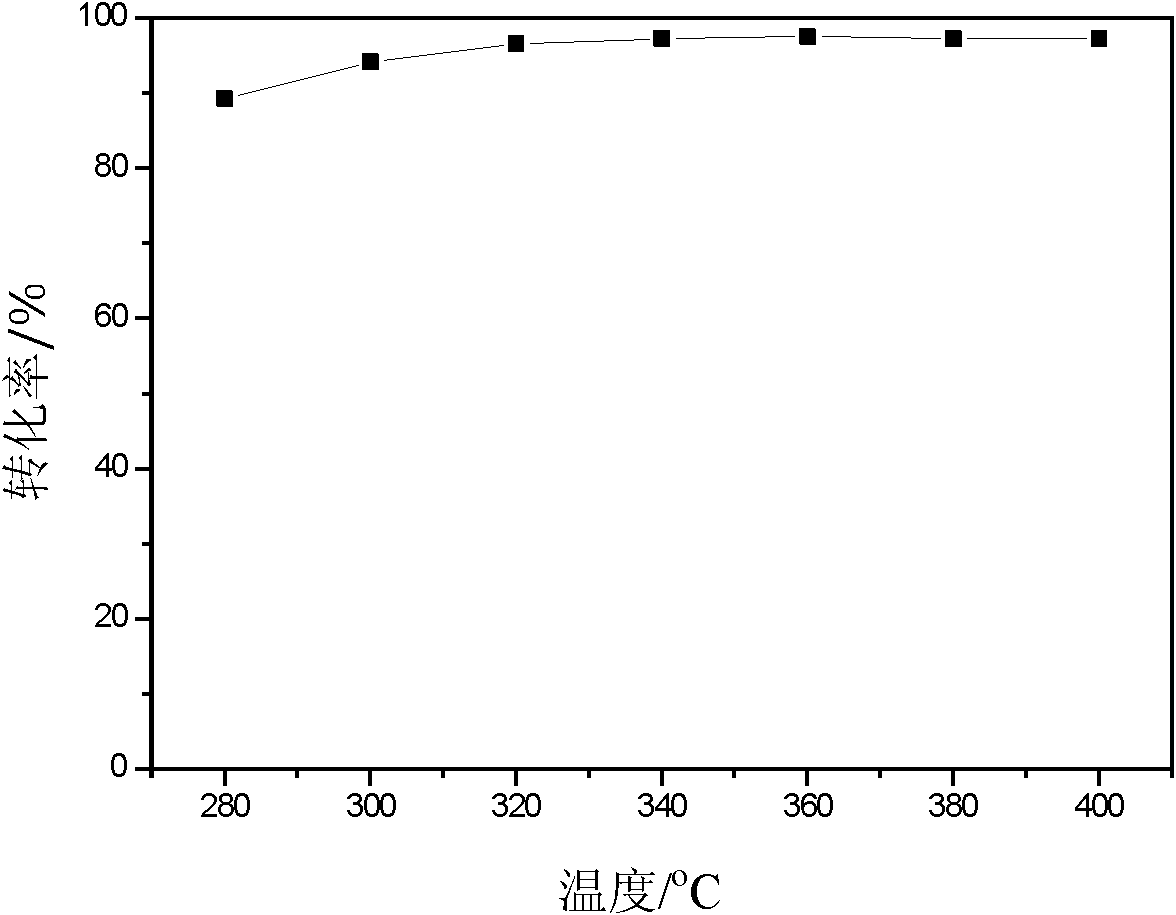

[0046] Commercial metatitanic acid was calcined at 500°C for 4 hours to obtain titanium dioxide. The average particle size was measured by a laser particle size analyzer to be 1.6 μm, and the specific surface area was 70 m by BET analysis. 2 / g. Mix 882g of the above-mentioned titanium dioxide, 112g of cerium-zirconium composite oxide powder with a cerium-zirconium molar ratio of 4:1 prepared by homogeneous precipitation method, and 97.7g of ammonium paratungstate, and then add them into the kneader. Get 50mL of 25% ammonia water and 300mL of deionized water to make a solution, add it into the kneader and start kneading. 54.5 g of kaolin, 23 g of methylcellulose, 32.5 g of glass fiber and 25 g of glycerin were also added during the kneading process. Knead for a period of time until the material is uniform and the water content is appropriate to obtain catalyst sludge. After the catalyst mud is stale for 24 to 48 hours, vacuum mud refining is started. After the drilled mud i...

Embodiment 3

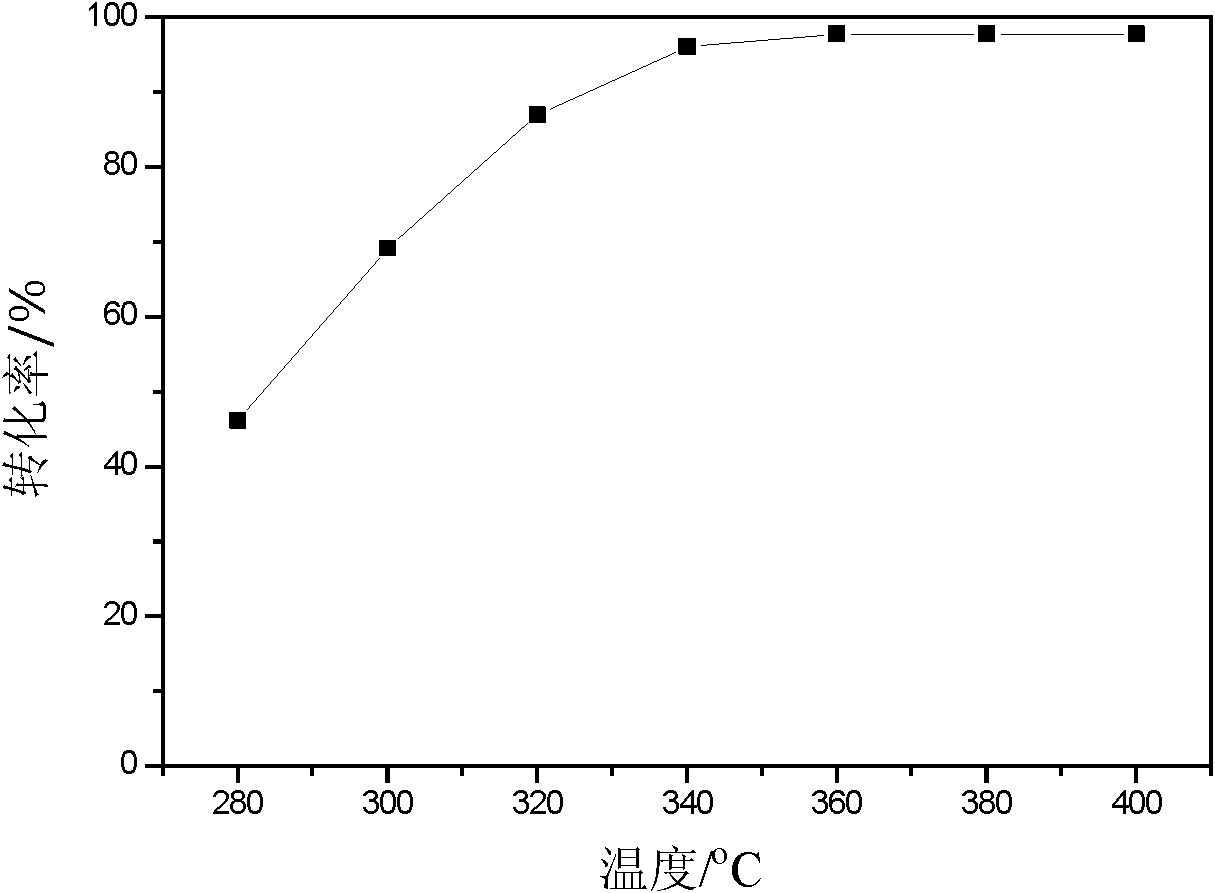

[0050] Commercial metatitanic acid was calcined at 500°C for 4 hours to obtain titanium dioxide. The average particle size was measured by a laser particle size analyzer to be 1.6 μm, and the specific surface area was 70 m by BET analysis. 2 / g. Mix 792g of the above-mentioned titanium dioxide, 90g of cerium oxide powder prepared by the solution combustion synthesis method, and 97.7g of ammonium paratungstate and add them into the kneader. Take 50mL of 25% ammonia water and 300mL of deionized water to make a solution, add it into the kneader and start kneading. 54.5 g of kaolin, 23 g of methylcellulose, 32.5 g of glass fiber and 25 g of glycerin were also added during the kneading process. Knead for a period of time until the material is uniform and the water content is appropriate to obtain catalyst sludge. After the catalyst mud is stale for 24 to 48 hours, vacuum mud refining is started. After the drilled mud is placed for 24 hours, it is extruded by a hydraulic piston e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com