Preparation method and application of amphiphatic copolymer modified chitosan compound

A technology of copolymer and chitosan, which is applied in the field of biomedical materials, can solve problems such as inability to remove, insufficient cross-linking degree, and increase gel cytotoxicity, so as to avoid weak toxicity, increase toughness and flexibility, and shorten biodegradation cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the preparation of lactic acid and malic acid amphiphilic copolymer:

[0019] In a 100 ml round bottom flask, add 5 g of lactic acid, 10 g of L-malic acid mixture and 0.10 g of zinc lactate crystals, slowly raise the temperature and heat to 110°C for 1 hour, connect the water pump and continue the reaction for 14 hours to obtain a white solid Amphiphilic copolymer product.

Embodiment 2

[0020] Embodiment 2: In 100 milliliters of round bottom flasks, change the ratio of L-malic acid and lactic acid, respectively according to the weight ratio of lactic acid and L-malic acid is 1: 1, 1: 2, 1: 3, 1: 5, 1 : 8 and 1: 10, adopt the similar condition reaction among the embodiment 1, can obtain a series of copolymers.

Embodiment 3

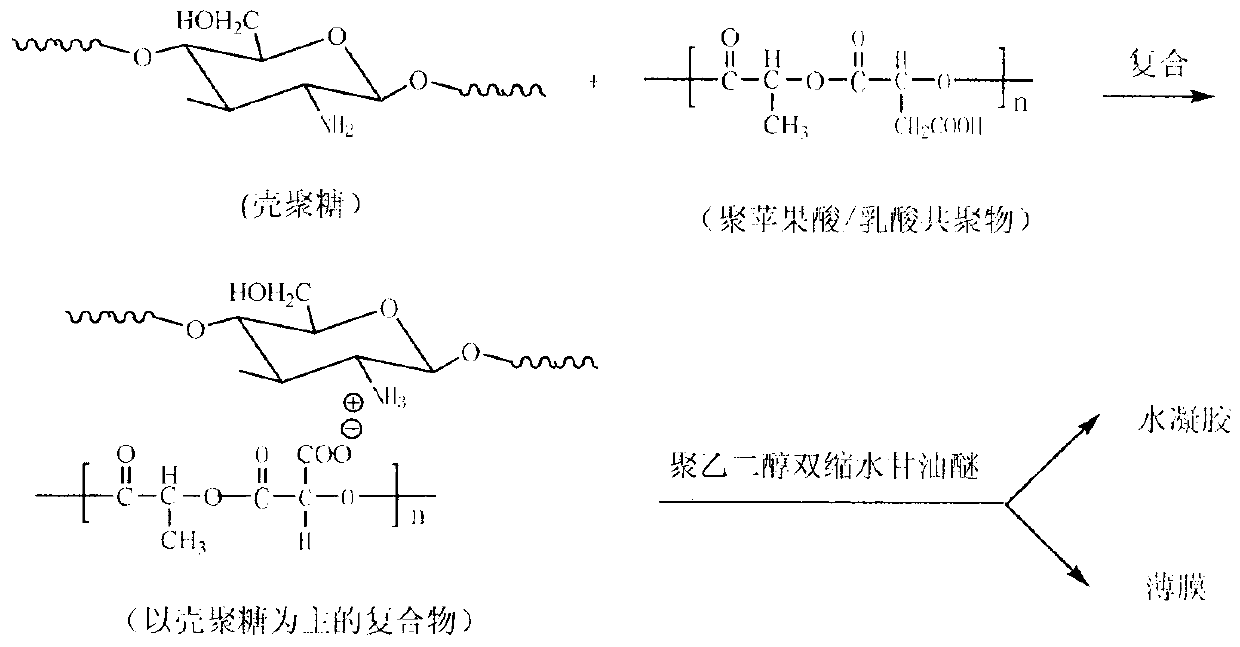

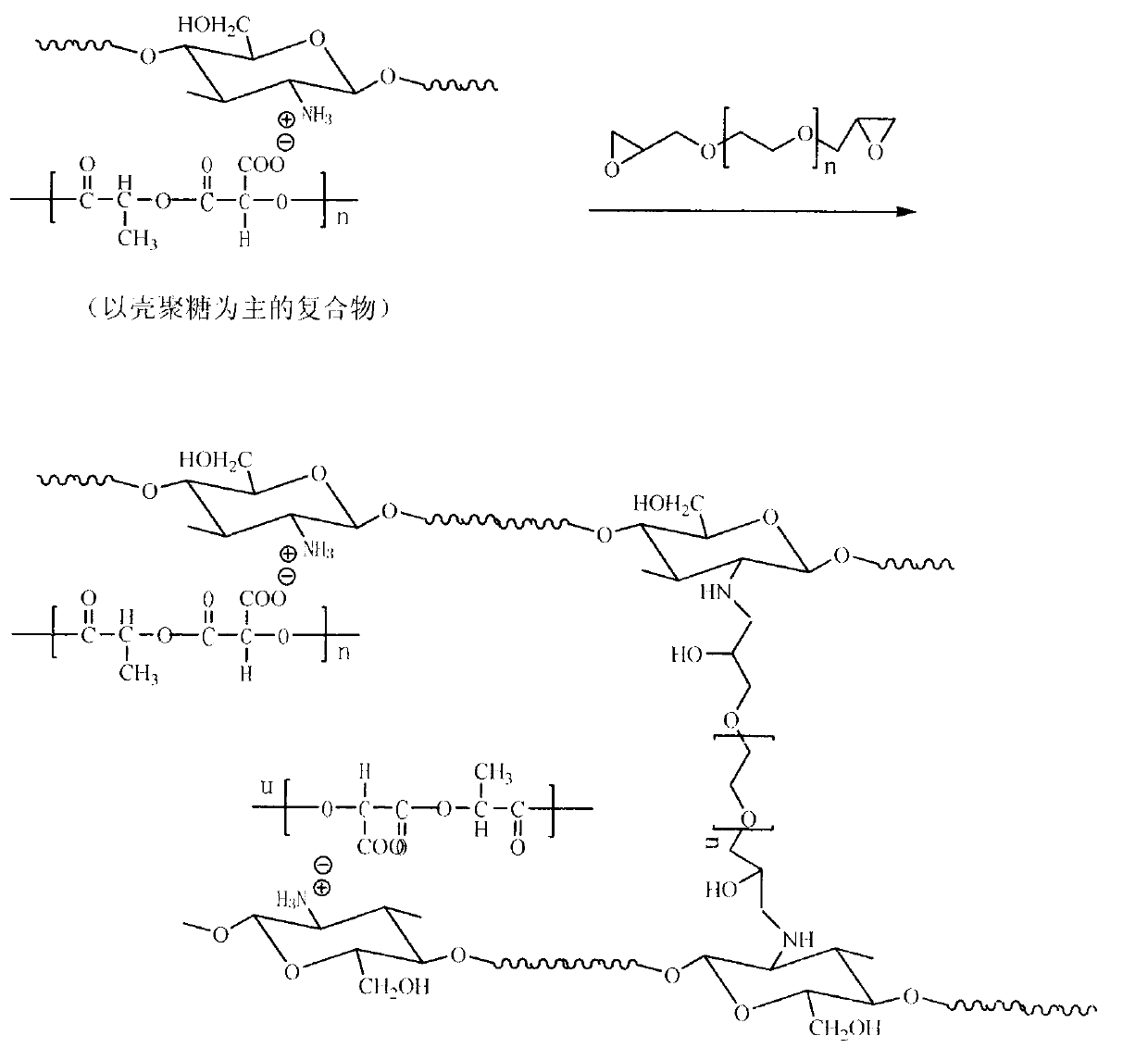

[0021] Embodiment 3: the preparation of amphiphilic copolymer and chitosan complex:

[0022] Add 2.5 grams of water-soluble chitosan and 80 milliliters of distilled water in a 250 milliliter beaker, soak and stir until forming a uniform chitosan solution. A 1:2 copolymer of lactic acid and L-malic acid is prepared as a 3.0% aqueous solution, and 12 milliliters of this solution is slowly dripped into the chitosan aqueous solution under stirring to form a complex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com